- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

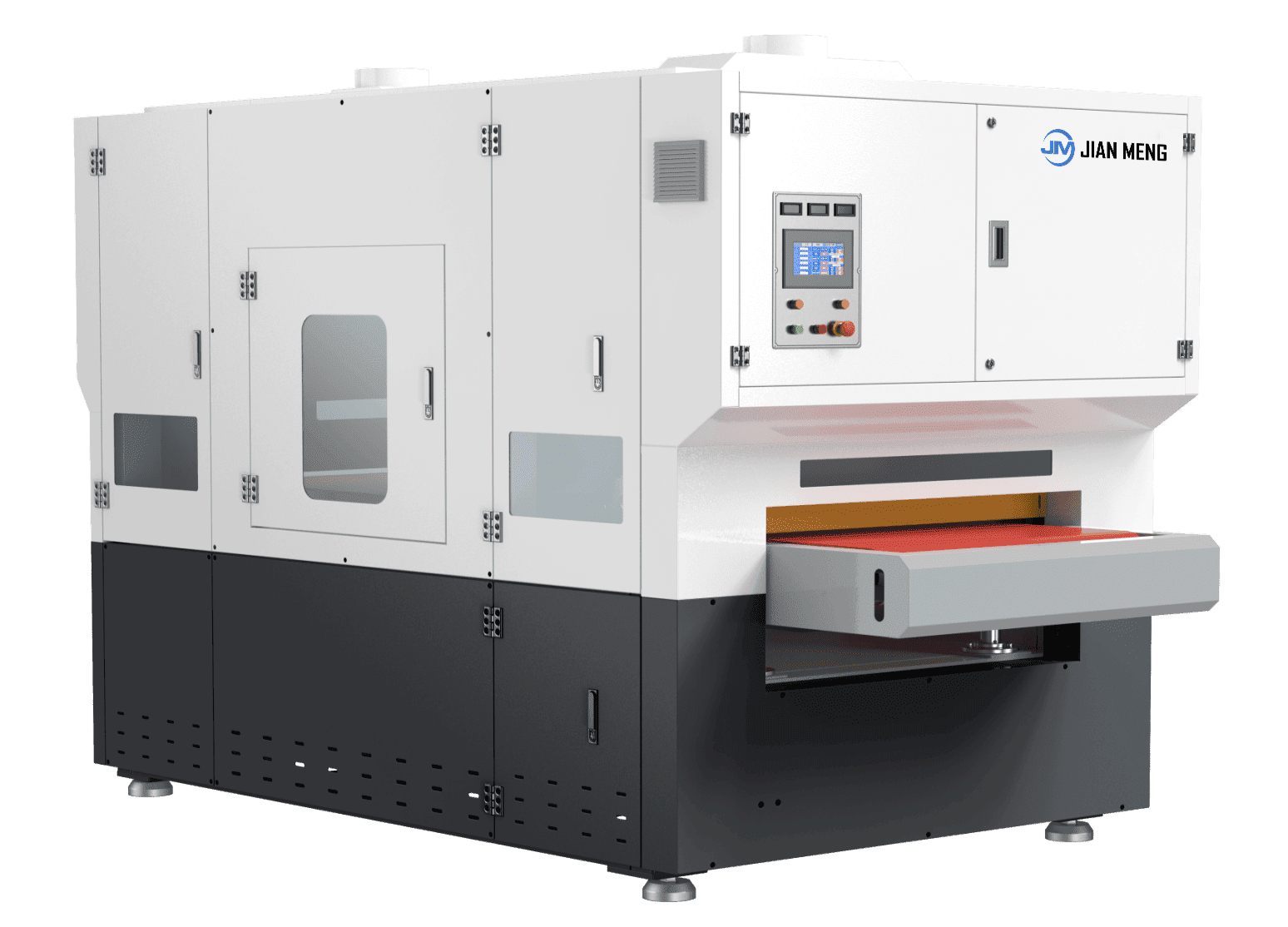

China Steel Sheet V Groove Notching Machine Manufacturers, Suppliers, Factory

Our purpose would be to give good quality items at competitive rates, and top-notch service to consumers around the world. We are ISO9001, CE, and GS certified and strictly adhere to their quality specifications for Steel Sheet V Groove Notching Machine,Automatic V Groove Notcher,Automatic V Groove Welding System,Precision V Groove Shearing Machine,Precision V Groove Welding Equipment, Never-ending improvement and striving for 0% deficiency are our two main quality policies. Should you need anything, never hesitate to get in touch with us.

Steel Sheet V Groove Notching Machine, we have now complete material production line, assembling line , quality control system, and the most importantly, we now have many patents technology and experienced technical&production team, expert sales service team. With all those advantages, we're about to create"the reputable international brand of nylon monofilaments", and spreading our solutions to every corner of the world. We've been keep moving and try our best to serve our customers.

Hot Products

CNC Horizontal High Speed V Grooving Machine

The CNC Horizontal High Speed V Grooving Machine is a stable V grooving equipment produced by JM, the Chinese manufacturer with the most types of V grooving machines. The CNC horizontal high speed V grooving machines is the most cost-effective grooving machine at medium to low utilization rates.Horizontal High Speed V Groove Cutting Machine

The horizontal high speed V groove cutting machine is a professional V groove cutting equipment produced by JM, the Chinese manufacturer with the most types of V groove cutting machines. The horizontal high speed cutting machines have high cost-effectiveness at medium to low utilization rates.Horizontal Double Drive Cutting Machine

The Chinese professional manufacturer of V grooving machine JM has the most types of V grooving machines, the CNC horizontal double drive cutting machine from it makes the dissimilar work processing is convenient.CNC Vertical High Speed V Slotting Machine For Stainless Steel Plates

The V grooving machine manufacturer JM in China provides the professional CNC vertical high speed V slotting machine for stainless steel plates with high energy efficiency and low maintenance, it can significantly improve production energy efficiency and slot speed.Vertical Back And Forth V Cutting Machine

The professional V cutting machine manufacturer and supplier JM in China offer customer from all over the world the excellent vertical back and forth V cutting machine. The vertical back and forth cutting machine have all characteristics of traditional V cutting machine.Vertical Laser & V Cutting Machine for Sheet Metal

JIANMENG Laser Cutting Machine integrates high-precision laser cutting, intelligent V-grooving, and fully automated production into one system, enabling one-stop processing from flat sheet to finished workpiece. V Grooving & Laser Integrated Machine achieves positioning accuracy of up to ±0.1 mm, delivering smooth, burr-free, deformation-free edges, and is capable of machining complex irregular shapes and sharp, reflection-free bends. Vertical Laser & V Cutting Machine intelligent control system connects directly to engineering drawings, automatically completing cutting path planning, process parameter matching, and continuous whole-sheet processing. Compared with traditional multi-machine, step-by-step workflows,V Grooving & Laser Integrated Machine boosts efficiency by more than three times, reduces process changeover time by over 80%, and ensures top-tier standards in dimensional accuracy, surface quality, and design complexity—making it the ideal choice for high-end architectural decoration and artistic installations.