China Precision V Groove Shearing Machine Manufacturers, Suppliers, Factory

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our firm for the long-term to create jointly with consumers for mutual reciprocity and mutual reward for Precision V Groove Shearing Machine,Automatic V Groove Notcher,Automatic V Groove Welding System,Precision V Groove Welding Equipment,Steel Sheet V Groove Bending Machine, Being a young escalating company, we might not the top, but we're trying our best to generally be your superior partner.

Precision V Groove Shearing Machine, The credibility is the priority, and the service is the vitality. We promise we now have the ability to supply excellent quality and reasonable price products and solutions for customers. With us, your safety is guaranteed.

Hot Products

V-Shaped Grooving Machine

The horizontal high speed v-shaped grooving machine is a professional V grooving equipment produced by JM, a manufacturer in China with the most types of V grooving machines. The horizontal high speed v-shaped grooving machines have high economic benefits and cost-effectiveness at medium to low utilization rates.Horizontal Double Drive V Slotting Machine For Stainless Steel Plate

The professional V grooving machine manufacturer JM in China not only has excellent horizontal double drive V slotting machine for stainless steel plate, but also provide considerate after-sales service. The groove processed by horizontal double drive V slotting machine for stainless steel plate is as smooth as a mirror.CNC Thin Sheet Deburring Machine

JM is a leading manufacturer specializing in CNC Thin Sheet Deburring Machine.The deburring machine is primarily used for deburring and chamfering the surfaces of various metal workpieces to improve surface quality. The JM deburring machine combines two functions: abrasive belt deburring and roller brush chamfering, allowing multiple surface processing steps to be completed in a single operation, thus enhancing production efficiency and product quality stability. It is suitable for materials such as stainless steel, aluminum alloy plates, steel plates, and copper plates. Different parameters can be adjusted, and appropriate abrasives can be selected based on processing requirements. JM Thin Sheet Deburring Machine, with its high efficiency, stability, and intelligent features, provides a one-stop surface treatment solution for metal processing enterprises. Whether it is improving workpiece quality or enhancing production efficiency, this machine meets all processing demands, making it an essential piece of equipment for modern manufacturing.Wet Metal Deburring & Brushing & Polishing Machine

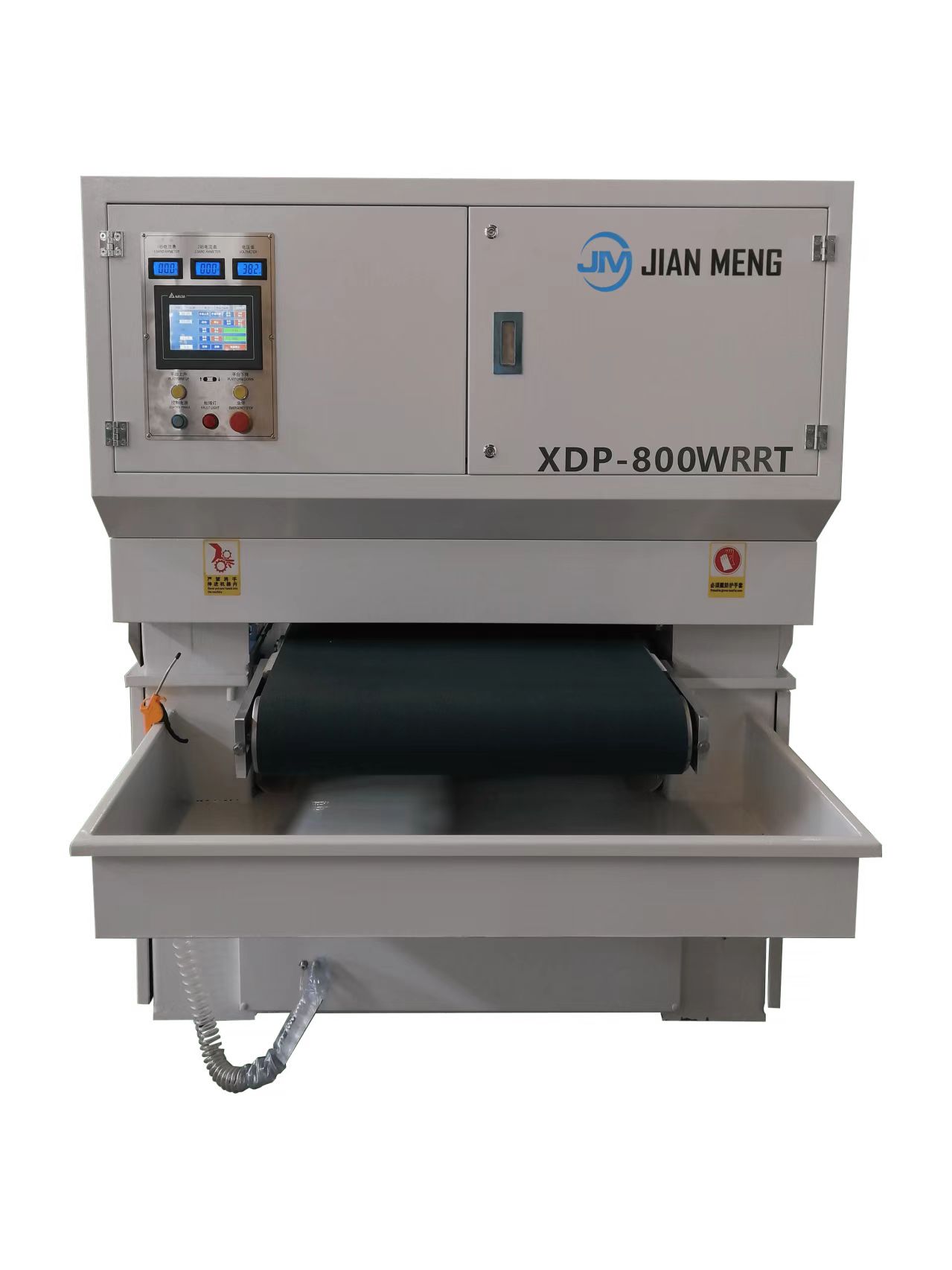

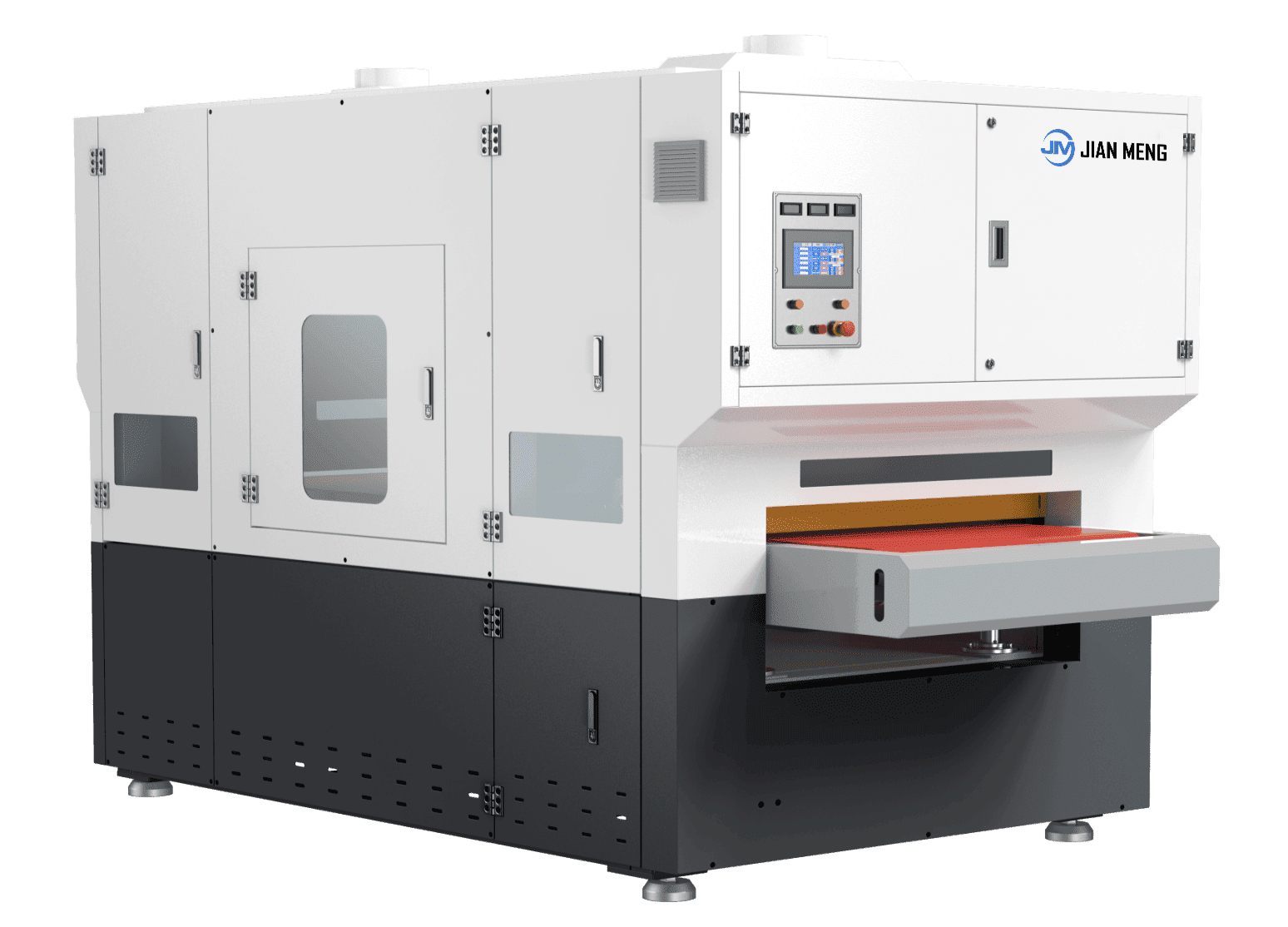

JM Wet Deburring Machine is a high-performance solution designed to efficiently remove burrs, slag, oxide layers, and sharp edges from metal sheets and plates. Utilizing wide abrasive belts in a wet processing environment, it delivers smooth, consistent surface finishes while eliminating harmful dust emissions. This makes it especially effective for post-processing after laser cutting, plasma cutting, or shearing. Equipped with a dual abrasive belt system, the machine ensures fast and uniform material removal across large surfaces. The wet grinding process not only cools the metal during operation—preventing heat-related distortion—but also extends the life of consumables. Its integrated filtration and water recirculation system supports clean, low-maintenance operation. Engineered for materials like stainless steel, aluminum, and copper, this sheet metal deburring machine is widely used in sectors including kitchen appliance manufacturing, electronics, and general metalworking. Compared to dry processing methods, it provides better surface quality, enhances workplace safety, and promotes environmentally responsible manufacturing.Deburring Polishing & Brushing & Chamfering Machine

JM Deburring & Brushing Machine stands at the forefront of metal surface treatment technology, specializing in the development of advanced Deburring, Polishing & Brushing Machines. Our solutions combine multiple processes—deburring, polishing, oxide removal, chamfering, and surface brushing—into one streamlined operation. Designed for industries such as sheet metal fabrication, automotive components, and precision instruments, Metal Finishing Machine delivers exceptional results across materials including stainless steel, carbon steel, aluminum, and copper. It removes burrs, sharp edges, and surface imperfections with ease, ensuring clean, safe, and consistent finishes. With a focus on efficiency, reliability, and intelligent control, Metal Finishing Machine help manufacturers enhance both product quality and throughput. By integrating superior performance with user-friendly operation, we provide a complete surface finishing solution that drives productivity and consistency. For companies seeking to raise their standards in metalworking, Deburring & Brushing Machine offers the trusted choice in achieving flawless surface quality and optimized production efficiency.CNC Carbon Steel Deburring &Brushing& Edge roundingBrushing Machine

The deburring and chamfering machine is specifically designed for surface treatment of carbon steel components. Automatic Deburring Machine features an innovative combination of three sets of wide abrasive belts and six universal rotary brushes for chamfering. This design ensures efficient and precise removal of surface burrs while achieving edge chamfering and surface brushing, significantly improving the surface quality and appearance of the workpiece. The Deburring & Brushing&edge rounding Machine meets the precision and quality requirements of carbon steel surface treatment across various industries, enhancing both production efficiency and product value. Parameters can be adjusted according to different processing needs, and suitable abrasives can be selected accordingly. The metal deburring machine is equipped with one 5.5kW wet dust collector. Dust removal method: The dust generated during operation is effectively extracted through a dust collection port, eliminating most of the dust, preventing potential dust explosion hazards, and keeping the internal structure clean.