- Horizontal V Grooving Machine

- Vertical V Grooving Machine

- Automatic Four Side V Grooving Machine

- V Grooving Machine Accessory

- Metal Forming Machine

- Deburring Machine

- Thin Sheet Deburring Machine

- Abrasive Belt Deburring Machine

- Carbon Steel Deburring Machine

- Deburring and Brushing Machine

- Manual Deburring Machine

- Wet Dust Collector

- Deburring Polishing & Brushing Machine

- Deburring & Chamfering Machine

- Wet Deburring & Brushing Machine

- Deburring, Edge rounding & Polishing Machine

- Carbon Steel Deburring & Brushing & Edge rounding Machine

- Dry Deburring, Brushing, and Polishing Machine

- Deburring and Brushing Machine with Slag Hammer Disc

- Shearing Machine

- Press Brake

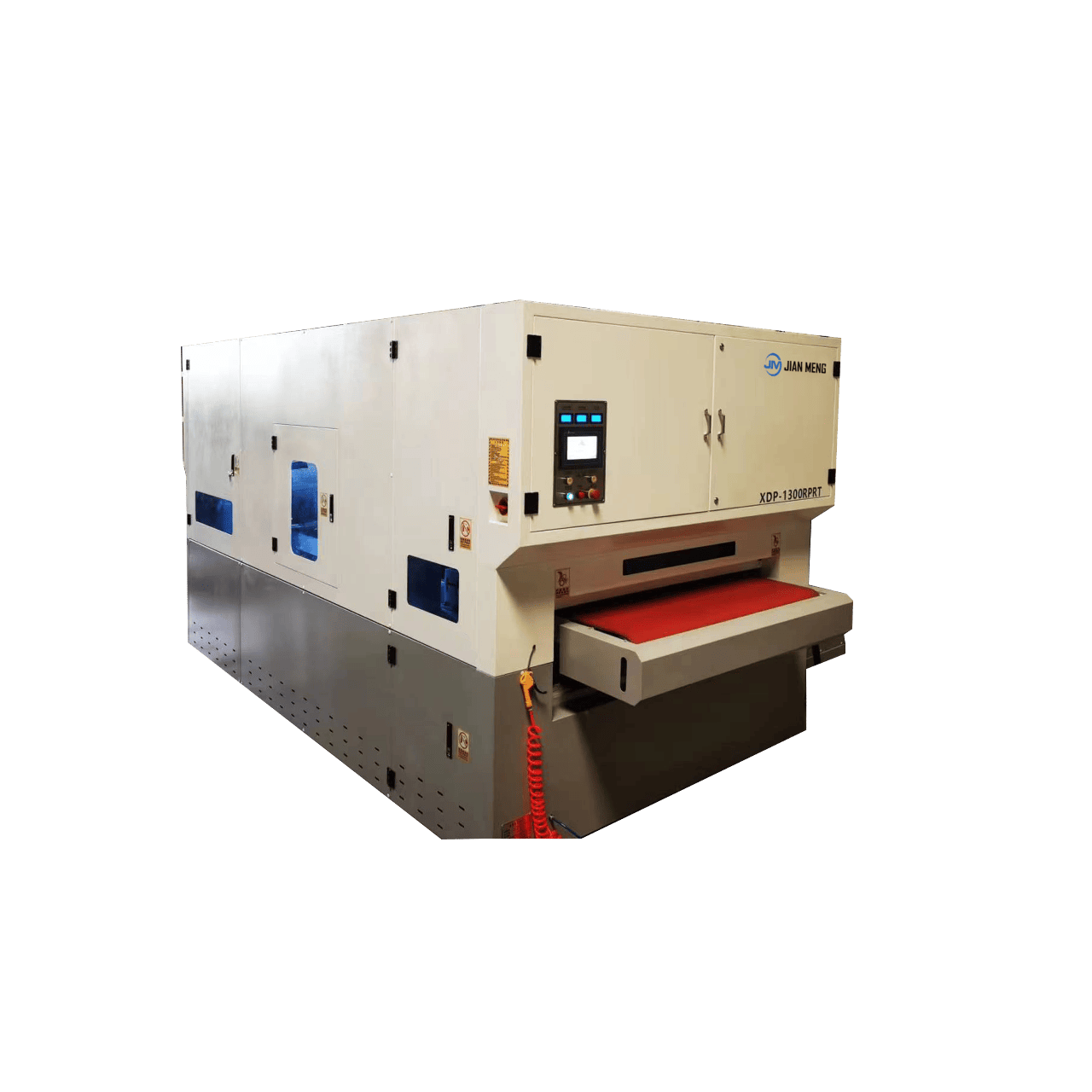

Deburring Polishing & Brushing & Chamfering Machine

JM Deburring & Brushing Machine stands at the forefront of metal surface treatment technology, specializing in the development of advanced Deburring, Polishing & Brushing Machines. Our solutions combine multiple processes—deburring, polishing, oxide removal, chamfering, and surface brushing—into one streamlined operation. Designed for industries such as sheet metal fabrication, automotive components, and precision instruments, Metal Finishing Machine delivers exceptional results across materials including stainless steel, carbon steel, aluminum, and copper. It removes burrs, sharp edges, and surface imperfections with ease, ensuring clean, safe, and consistent finishes. With a focus on efficiency, reliability, and intelligent control, Metal Finishing Machine help manufacturers enhance both product quality and throughput. By integrating superior performance with user-friendly operation, we provide a complete surface finishing solution that drives productivity and consistency. For companies seeking to raise their standards in metalworking, Deburring & Brushing Machine offers the trusted choice in achieving flawless surface quality and optimized production efficiency.

Model:XDP-1000RPRT

Send Inquiry

Deburring Machines

Perfect Deburring: The XDP-1000RPRT Deburring, Polishing & Brushing Machine is designed to deliver precise edge processing for metal parts, sheets, and plates by removing burrs and sharp edges created during manufacturing. Precision Deburring Machine ensures a smooth, safe, and high-quality surface finish. Beyond edge treatment, the machine also removes oxide layers and heat-affected zones left after welding, greatly enhancing the adhesion of coatings and paints. With its comprehensive surface preparation capabilities, the XDP-1000RPRT is an indispensable solution for improving both the appearance and performance of metal components across diverse industrial applications.

|

Main configuration list |

PCL touch screen(7-inch): Delta |

|

Abrasive belt motor(11kW): Huarui |

|

|

Roller brush self-rotation motor(2.2kW): Huarui |

|

|

Roller brush orbital motor (1.5kW): Jinwanshun |

|

|

Vacuum suction fan (15kW): Jiuzhou Puhui |

|

|

Wet dust collector motor (5.5kW): Jiuzhou Puhui |

|

|

Control buttons: Schneider (France) |

|

|

Solenoid valve: Airtac |

|

|

Pneumatic components: Mobang |

CNC Display Screen

The CNC display screen of the deburring machine is a key component of the equipment, responsible for centrally displaying and controlling all operation parameters during the deburring process, improving processing efficiency and precision. The CNC display not only provides real-time feedback but also allows the operator to make precise parameter adjustments according to the needs, ensuring the quality of the workpiece.

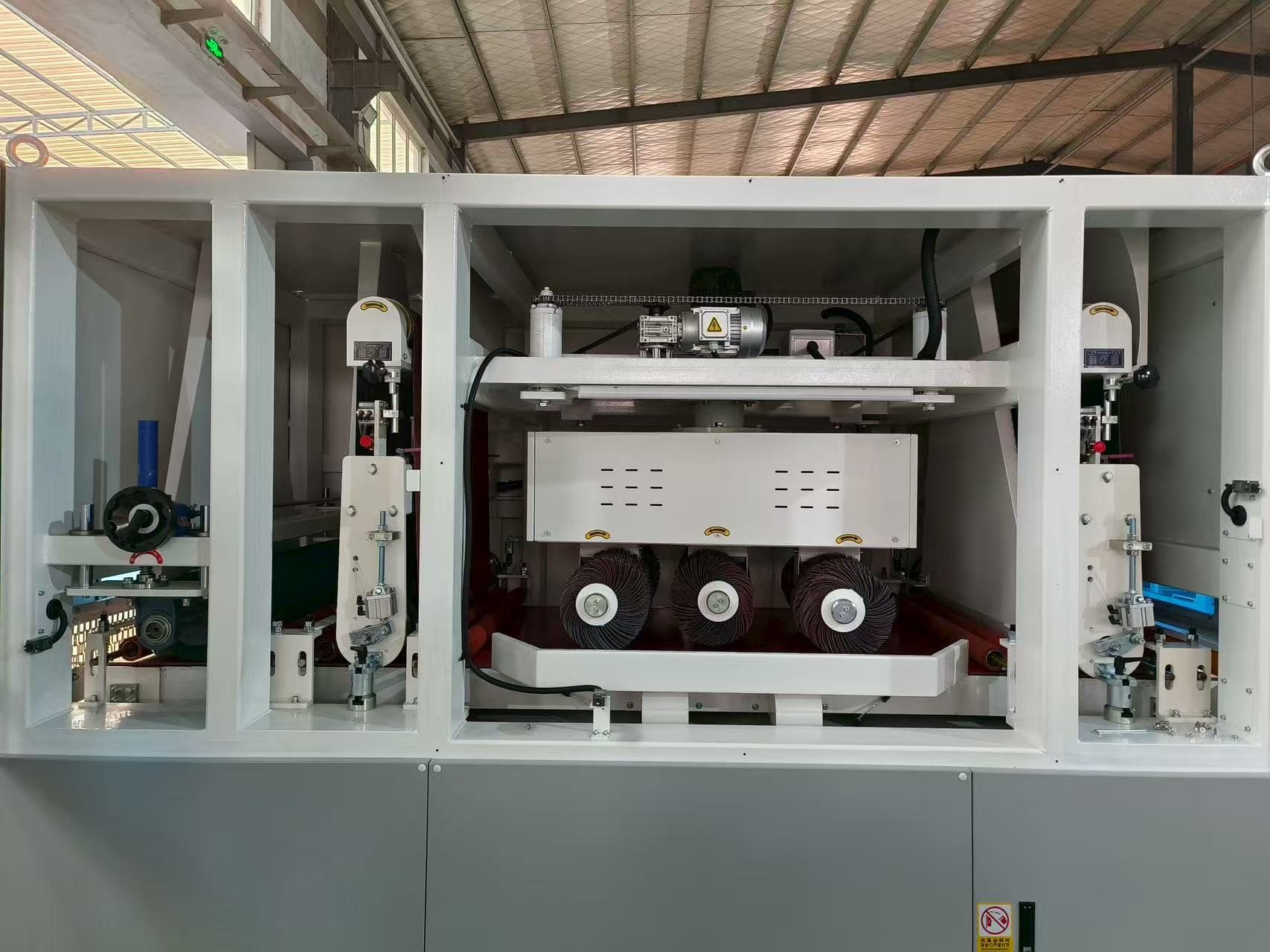

Internal Structure

The internal structure of the 1000RPRT consists of one set of abrasive belts + six roller brushes + one set of abrasive belts + one polishing roller, forming a four-stage processing system. The first abrasive belt is used for the initial removal of burrs from the workpiece surface; the second stage with six roller brushes performs brushing treatment, ensuring thorough deburring without damaging the surface; the second set of abrasive belts provides further fine grinding to improve surface flatness; and finally, the polishing roller carries out precision polishing, making the surface smooth, uniform, and visually refined. With its well-designed structure, the machine enables efficient, stable, and continuous surface treatment.

Consumables

Abrasive Belt

Abrasive belts are widely used as abrasive tools for metal surface treatment. After undergoing special processing, they are formed into a belt structure, suitable for various tasks such as grinding, deburring, polishing, finishing, and wire drawing. The abrasive belt removes excess material through friction with the workpiece surface, improving the surface quality and appearance of the workpiece.

Roller brushes

The roller brush is a highly efficient tool for metal processing and surface treatment, widely used in deburring, brushing, cleaning, and removing oxide layers or oil residues. By rotating against the workpiece surface, its bristles deliver effective deburring, chamfering, and surface finishing, ensuring cleaner edges and an improved overall appearance.

Comparison of Before and After Deburring

Before deburring:

Workpieces often exhibit burrs, sharp edges, or protruding fins as a result of cutting, stamping, milling, sawing, or drilling. These imperfections can be accompanied by surface oxides, welding slag, oil stains, or other contaminants. Such defects not only compromise the surface quality but may also interfere with subsequent processing steps like coating, welding, or assembly.

After Deburring:

Following the deburring process, the workpiece surface becomes smooth, clean, and free of burrs and sharp edges. All irregular projections and sharp corners generated during manufacturing are effectively removed. Edges are more uniform and rounded, minimizing the risk of injury, reducing wear on tooling, and ensuring better performance and compatibility in downstream operations.

XDP-1000RPRT Machine Parameter

| Worktable width |

1000mm |

|

Maximum load capacity |

200kg |

|

Processing thickness |

1-100mm |

|

Minimum processing size |

(non-perforated plate) 50*50*0.5mm |

|

Abrasive belt size |

2200*1020 mm |

|

Polishing roller size |

Φ250*1020mm |

|

Roller brush size |

300*300*40 mm |

Clients’ Deburring Cases

A leading stainless steel component manufacturer was struggling with uneven edge finishing, low processing efficiency, and inadequate surface preparation that compromised coating and paint adhesion. After implementing the JM Deburring, Polishing & Brushing Machine, the company achieved notable improvements in production efficiency, edge uniformity, and overall surface quality—especially in removing weld oxidation and heat-affected zones. The intelligent automation of the system also minimized manual labor requirements and ensured greater process stability.