- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Horizontal V Grooving Machine

- Vertical V Grooving Machine

- Automatic Four Side V Grooving Machine

- V Grooving Machine Accessory

- Metal Forming Machine

- Deburring Machine

- Thin Sheet Deburring Machine

- Abrasive Belt Deburring Machine

- Carbon Steel Deburring Machine

- Deburring and Brushing Machine

- Manual Deburring Machine

- Wet Dust Collector

- Deburring Polishing & Brushing Machine

- Deburring & Chamfering Machine

- Wet Deburring & Brushing Machine

- Deburring, Edge rounding & Polishing Machine

- Carbon Steel Deburring & Brushing & Edge rounding Machine

- Dry Deburring, Brushing, and Polishing Machine

- Deburring and Brushing Machine with Slag Hammer Disc

- Shearing Machine

- Press Brake

Pneumatic Metal Forming Machine

JIANMENG specializes in advanced Metal Shaping Machine, engineered for high-precision, chip-free processing of metal sheets with exceptionally low noise. These Metal shrinker machine support a wide range of metal forming applications, making them an ideal solution for both manufacturing new components and performing precise adjustments or repairs on existing parts. With rapid tool change capabilities and smooth transitions between functions, JIANMENG solutions are designed to maximize flexibility and efficiency. The PMF 400Metal Shaping Machine stands out with its reinforced structure and significantly increased forming pressure, enabling it to handle more demanding tasks. Its modular die system supports a variety of easily interchangeable tools—including shrinker and stretcher toolings—offering unmatched adaptability in metal forming operations. Built for long service life, high precision, and multifunctionality, JIANMENG delivers next-generation forming technology that sets a new standard for efficiency, control, and performance in modern metal fabrication.

Model:PMF-400

Send Inquiry

Pneumatic forming machine

Metal Forming Machine is a low-noise, high-efficiency machine that uses pneumatic technology to achieve multifunctional processing such as metal precision forming, shrinking and stretching.

PMF 400 Metal Shrinking Machine Parameter

|

Horizontal throat |

400 mm |

|

Vertical throat |

500 mm |

|

Working stroke |

50 mm |

|

Working strokes per minute |

60-80 |

|

Cylinder thrust |

(0.6MPa) 1529 kg |

|

Air supply pressure |

0.5-0.8 MPa |

|

Weight |

350 kg |

Pneumatic Forming Machine Toolings

Kraftformer is configured with various tools, allowing for quick and easy die installation and replacement. This ensures optimal and purposeful utilization of the equipment. JIANMENG's integrated technology is globally leading.

Why book with us?

·New intelligent design

·Adjustable stroke speed

·Adjustable stroke frequency

·Tool monitoring

·Electronic counter

·Quick air on/off device

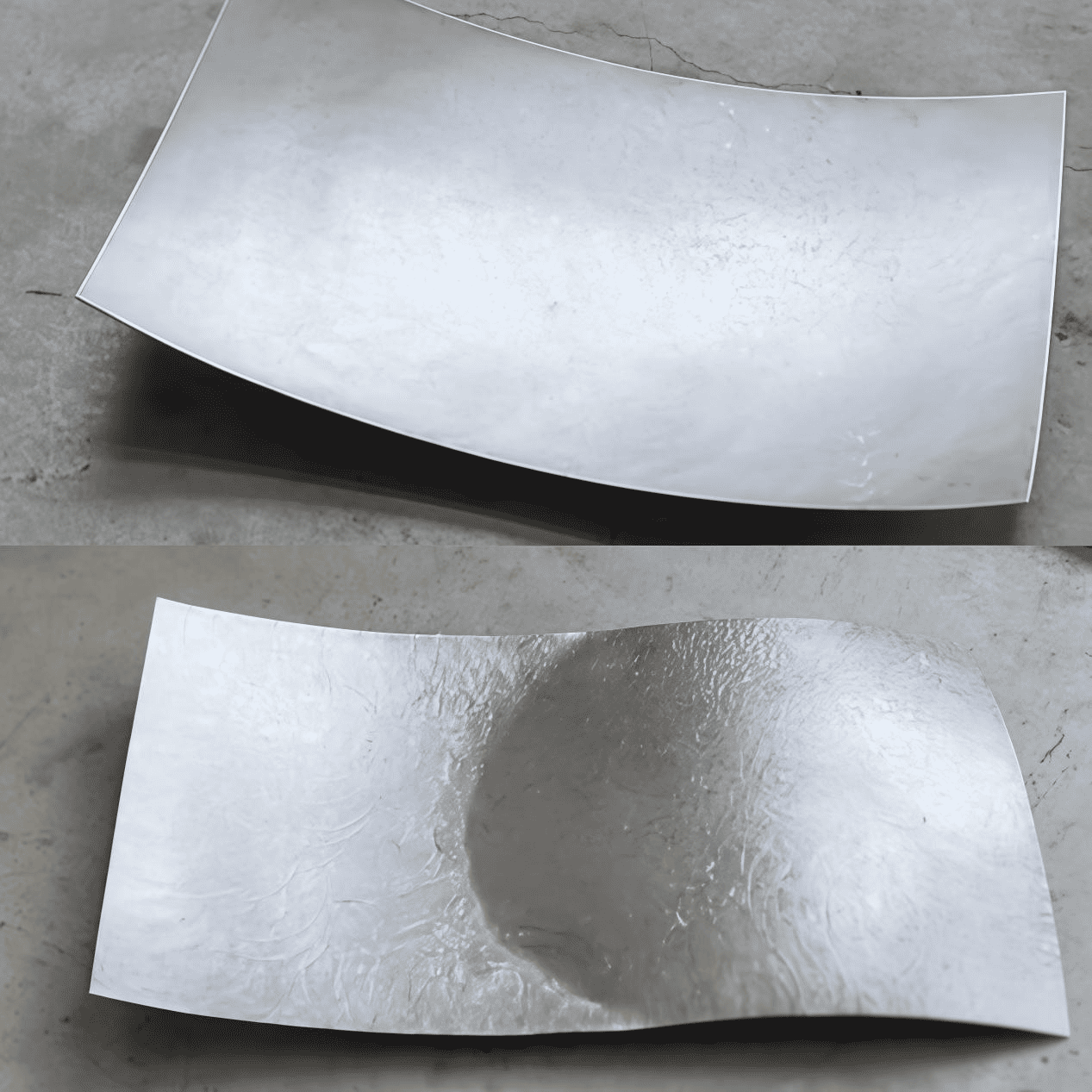

Before and after comparison of the workpiece

After precise shaping and forming by the pneumatic forming machine, the workpiece’s surface dimensions and shape become more accurate, with significant improvements in overall quality and appearance.

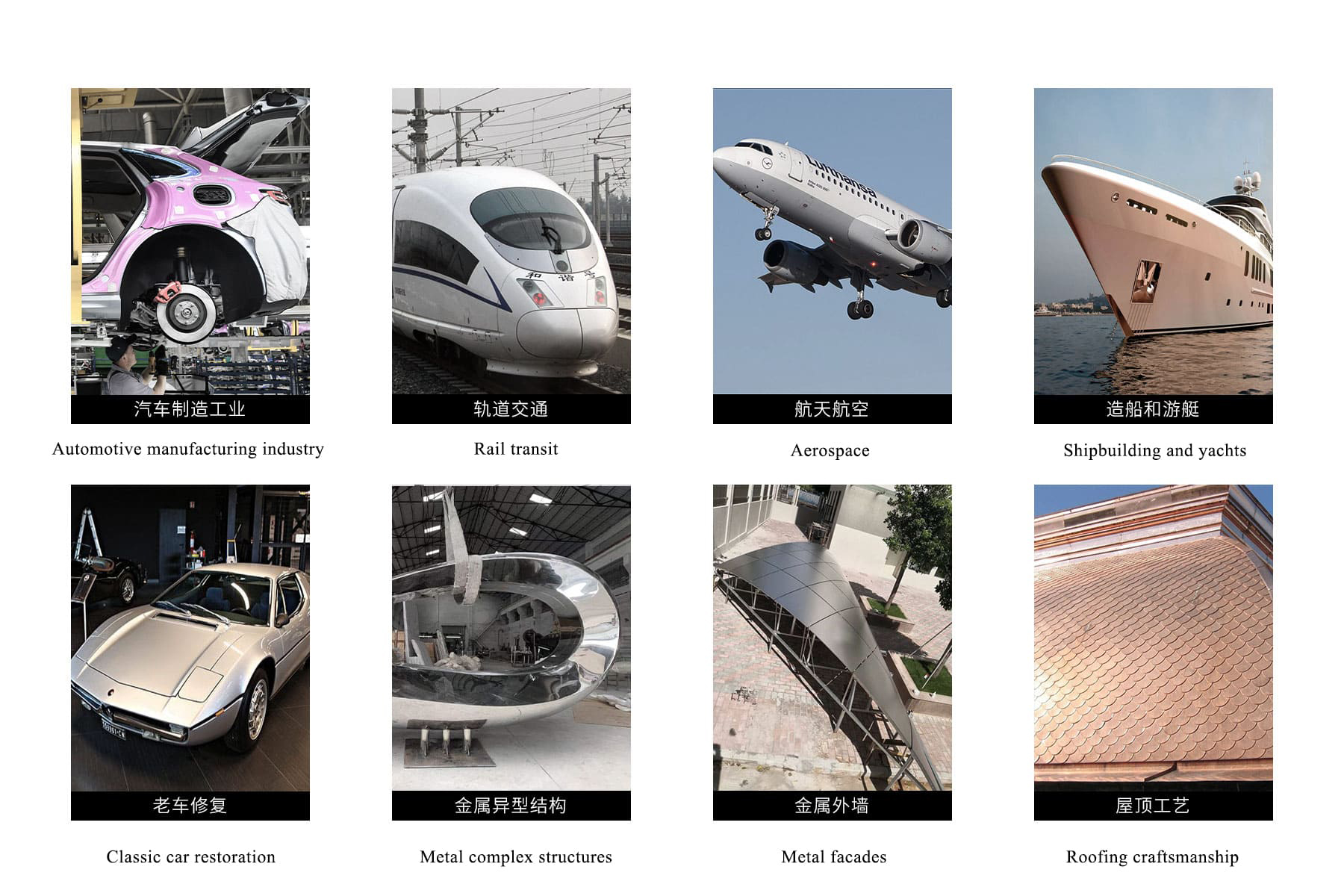

Industry application of pneumatic forming machine

JIANMENG Metal Shrinking Machines are widely used across various industries, including automotive manufacturing and repair, classic car restoration, shipbuilding, aerospace, metal sculpture, and metal art . With their high precision and multifunctional forming capabilities, these machines effectively support sheet metal restoration and metal work, especially for vintage car restoration and classic car body shaping.

In shipbuilding and aircraft manufacturing, JIANMENG Power machines enable the accurate forming and repair of complex, curved metal components. Additionally, they provide strong support to sculptors, metal artists, and craftspeople, helping them bring to life intricate, imaginative, and creative metal artworks, fostering a deep integration of industrial technology and artistic expression.