China Wet Deburring & Brushing Machine Manufacturers, Suppliers, Factory

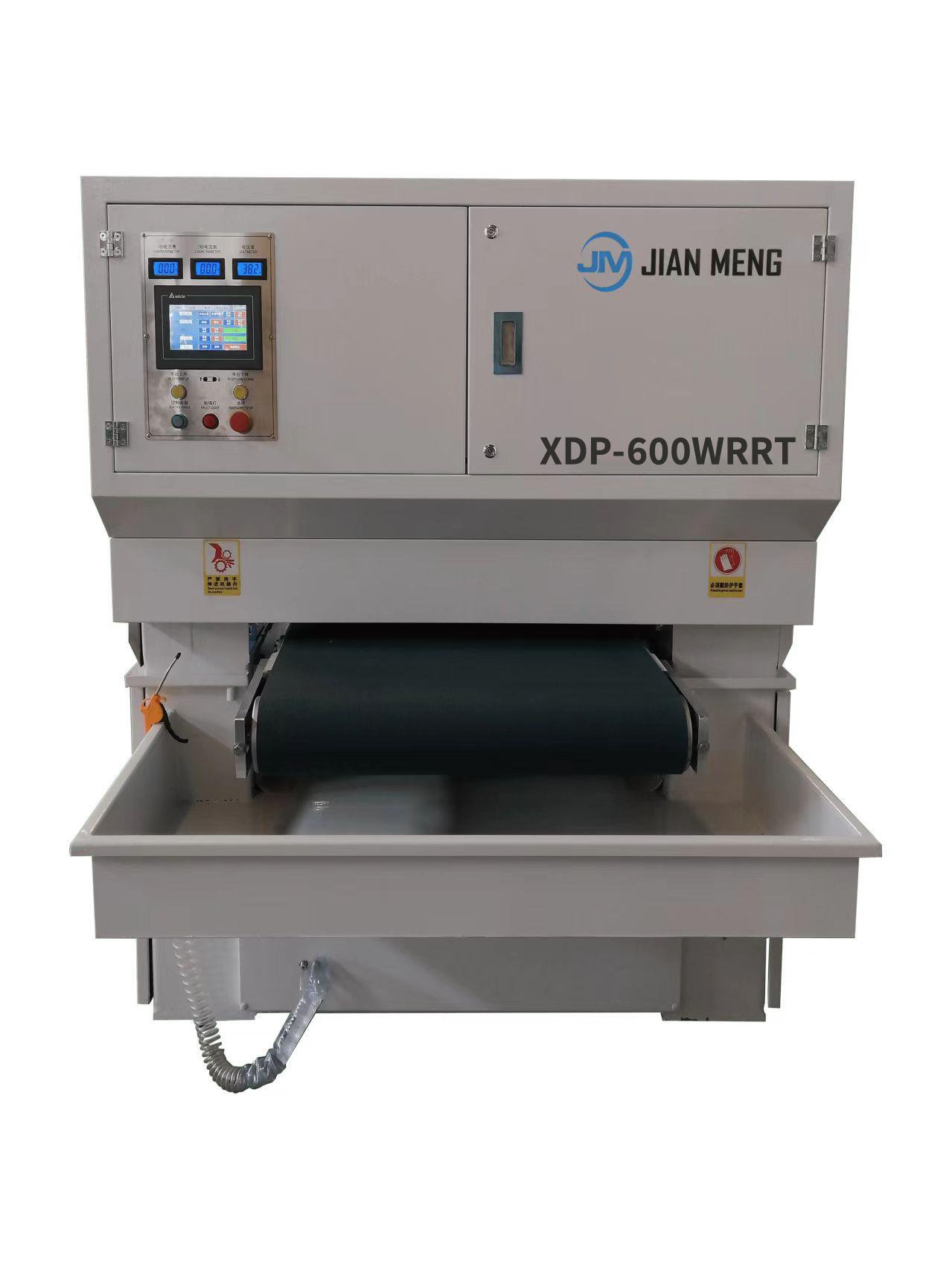

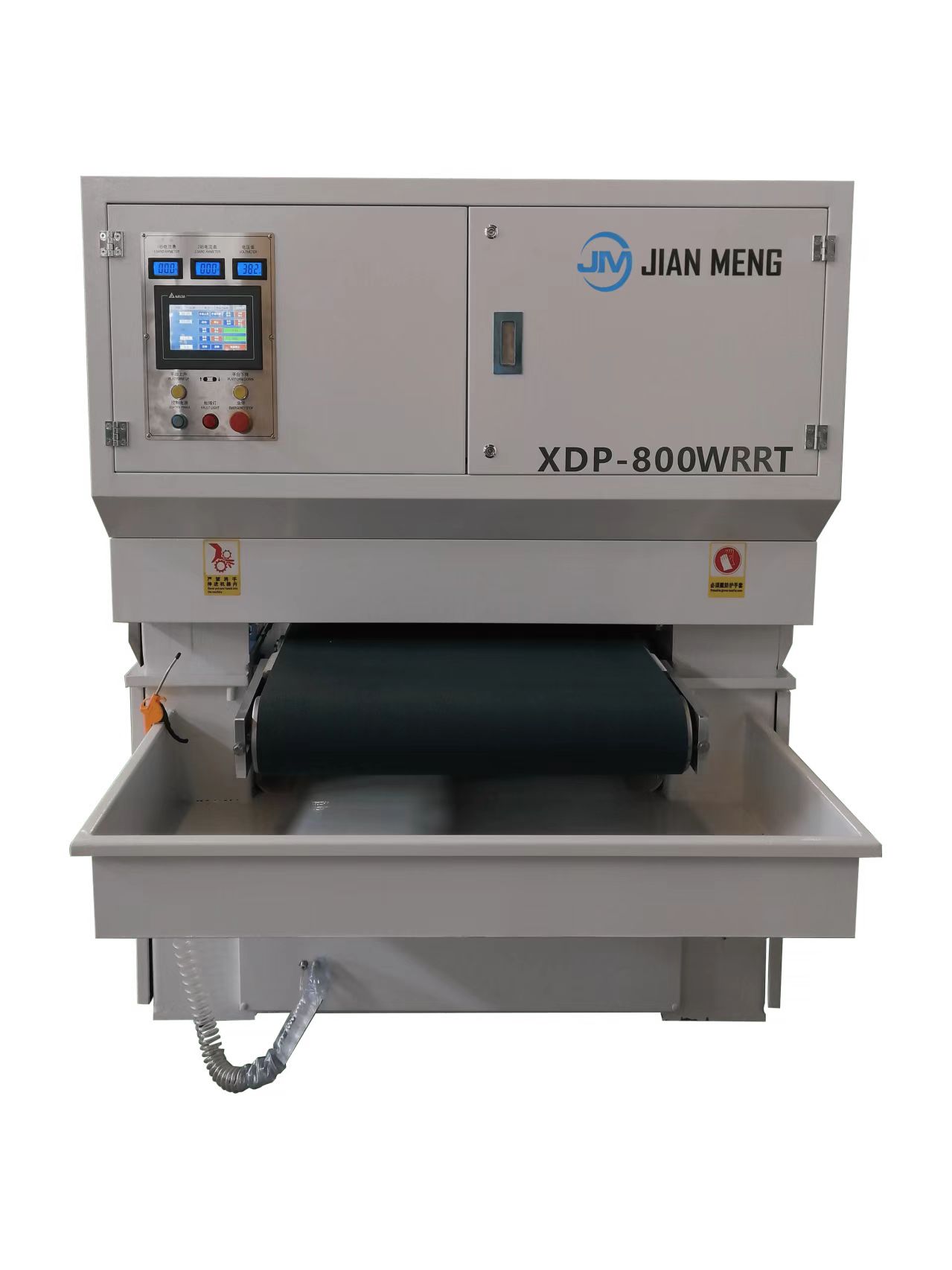

The Wet Deburring & Brushing Machine is a wet abrasive belt machine specially designed for metal sheet surface treatment, offering excellent capabilities in brushing, polishing, removing oxidation, and deburring. The machine features a dual abrasive belt system combined with a wet cooling process, which ensures efficient grinding while effectively reducing thermal deformation and dust generation, significantly enhancing surface quality. It is suitable for aluminum and copper.

The machine is built with a sturdy structure for stable operation and is equipped with a high-precision conveyor platform and an intelligent control system. It supports flexible adjustment for processing different material thicknesses. Each of the two sanding stations can operate independently to meet diverse process requirements. With servo motors and high-performance rubber rollers, the machine ensures consistent and tight contact with the workpiece throughout the process, making it ideal for high-standard, continuous production environments.

- Horizontal V Grooving Machine

- Vertical V Grooving Machine

- Automatic Four Side V Grooving Machine

- V Grooving Machine Accessory

- Metal Forming Machine

- Deburring Machine

- Thin Sheet Deburring Machine

- Abrasive Belt Deburring Machine

- Carbon Steel Deburring Machine

- Deburring and Brushing Machine

- Manual Deburring Machine

- Wet Dust Collector

- Deburring Polishing & Brushing Machine

- Deburring & Chamfering Machine

- Wet Deburring & Brushing Machine

- Deburring, Edge rounding & Polishing Machine

- Carbon Steel Deburring & Brushing & Edge rounding Machine

- Dry Deburring, Brushing, and Polishing Machine

- Deburring and Brushing Machine with Slag Hammer Disc

- Shearing Machine

- Press Brake

- View as

CNC Wet Metal Deburring & Brushing & Polishing Machine

JM Wet Deburring Machine is a high-performance solution designed to efficiently remove burrs, slag, oxide layers, and sharp edges from metal sheets and plates. Utilizing wide abrasive belts in a wet processing environment, it delivers smooth, consistent surface finishes while eliminating harmful dust emissions. This makes it especially effective for post-processing after laser cutting, plasma cutting, or shearing. Equipped with a dual abrasive belt system, the machine ensures fast and uniform material removal across large surfaces. The wet grinding process not only cools the metal during operation—preventing heat-related distortion—but also extends the life of consumables. Its integrated filtration and water recirculation system supports clean, low-maintenance operation. Engineered for m......

Read MoreSend InquiryWet Metal Deburring & Brushing & Polishing Machine

JM Wet Deburring Machine is a high-performance solution designed to efficiently remove burrs, slag, oxide layers, and sharp edges from metal sheets and plates. Utilizing wide abrasive belts in a wet processing environment, it delivers smooth, consistent surface finishes while eliminating harmful dust emissions. This makes it especially effective for post-processing after laser cutting, plasma cutting, or shearing. Equipped with a dual abrasive belt system, the machine ensures fast and uniform material removal across large surfaces. The wet grinding process not only cools the metal during operation—preventing heat-related distortion—but also extends the life of consumables. Its integrated filtration and water recirculation system supports clean, low-maintenance operation. Engineered for m......

Read MoreSend InquiryWet Deburring & Brushing Machine

JM Wet Deburring Machine is a specialized solution for removing burrs, slag, oxide layers, and sharp edges from metal sheets and plates. It operates using wide abrasive belts under wet conditions, ensuring clean, uniform surface finishing without producing harmful dust. This machine is ideal for improving surface quality after laser, plasma, or shear cutting. Featuring a dual abrasive belt structure, the metal finishing machine delivers high-speed, consistent material removal across a wide working width. Automatic deburring machine process cools the material during grinding, prevents thermal deformation, and enhances the lifespan of consumables. Its built-in filtration and water circulation system ensures clean operation and easy maintenance. Suitable for stainless steel, aluminum, co......

Read MoreSend Inquiry