China Precision V Groove Welding Equipment Manufacturers, Suppliers, Factory

We now have a skilled, performance team to supply good quality services for our consumer. We often follow the tenet of customer-oriented, details-focused for Precision V Groove Welding Equipment,Automatic V Groove Notcher,Automatic V Groove Welding System,Precision V Groove Shearing Machine,Steel Sheet V Groove Bending Machine, Our solutions are widely recognized and reliable by users and can satisfy continuously acquiring economic and social needs.

Precision V Groove Welding Equipment, Why we can do these? Because: A, We are honest and reliable. Our products have high quality, attractive price, sufficient supply capacity and perfect service. B, Our geographical position has a big advantage . C, Various types: Welcome your inquiry, It will be highly appreciated.

Hot Products

Horizontal High Speed V Slotting Machine

The horizontal high speed v slotting machine is a stable V grooving equipment produced by JM, the Chinese enterprise integrates the the research and development, production, sales and after-sales of v grooving machine. The horizontal high speed V slotting machines is cost-effective.Automatic Four Side V Groove Cutting Machine

JM is the professional China manufacturer and supplier of automatic four side V groove cutting machine with affordable price. If customers choose to use automatic four side V groove cutting machine, the workpiece no longer needs to be shifted manually, which greatly improves the dimensional accuracy, saves labor costs, saves time costs and improves production efficiency.KORLOY Knife

JM is a leading China KORLOY Knife manufacturers and suppliers. In order to help customers to survive in international competition, the Chinese V grooving machine manufacturer JIANMENG provide excellent equipment and accessory. The KORLOY knife offered by JIANMENG provide stable cutting quality and high productivity.Thick Sheet Deburring Machine

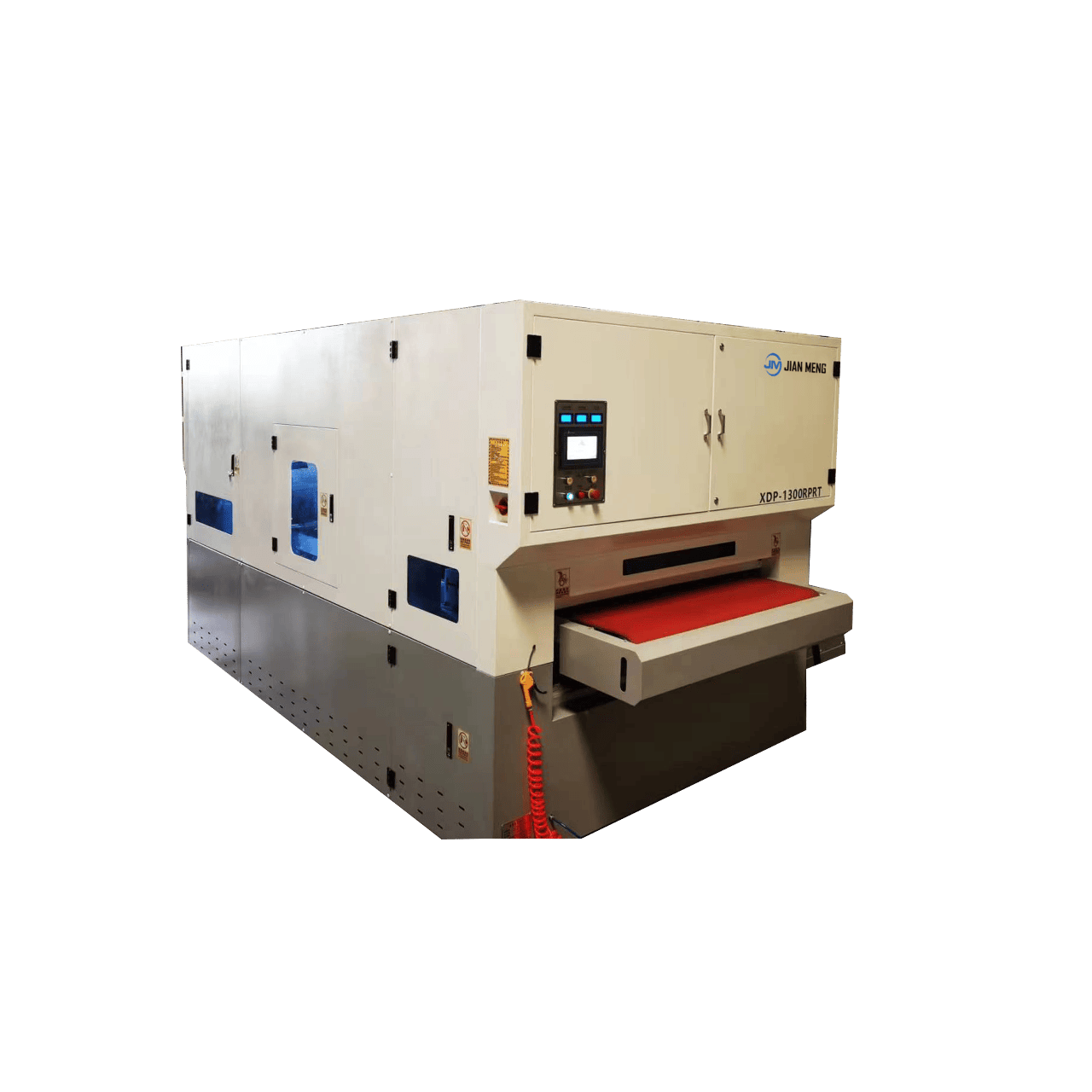

The deburring and chamfering machine is specifically designed for surface treatment of carbon steel components. It features an innovative combination of two sets of wide abrasive belts for deburring and four universal rotary brushes for chamfering. This design ensures efficient and precise removal of surface burrs while achieving edge chamfering and surface brushing, significantly improving the surface quality and appearance of the workpiece. The Deburring & Brushing Machine meets the precision and quality requirements of carbon steel surface treatment across various industries, enhancing both production efficiency and product value. Parameters can be adjusted according to different processing needs, and suitable abrasives can be selected accordingly. The metal deburring machine is equipped with one 5.5kW wet dust collector. Dust removal method: The dust generated during operation is effectively extracted through a dust collection port, eliminating most of the dust, preventing potential dust explosion hazards, and keeping the internal structure clean.Deburring Polishing & Brushing Machine for metal sheet

JM is a leading manufacturer dedicated to developing and producing advanced deburring, polishing, and brushing equipment that meets the highest standards of modern metal surface processing. This efficient and intelligent machine integrates deburring, polishing, oxide removal, chamfering, and surface brushing in one process. Widely used in sheet metal fabrication, automotive parts, and precision instruments, the Industrial Deburring Machine effectively removes burrs, sharp edges, and defects from stainless steel, carbon steel, aluminum, and copper, ensuring smooth and safe edges. Designed for high efficiency, stability, and smart operation, Automatic Deburring Machine enhances workpiece quality, improves consistency, and boosts production speed—providing manufacturers with a reliable, all-in-one surface treatment solution. For superior product quality and streamlined processing, JM’s equipment is the top choice for metalworking enterprises.Electro-Hydraulic Dual Servo Pump CNC Press Brake

This Electro-Hydraulic Dual Servo Pump CNC Press Brake is a high-performance, intelligent machine for sheet metal bending. Its core advantage is the energy-saving dual-servo pump system, which cuts electricity costs significantly. It guarantees extreme precision and consistent quality with automatic real-time adjustments, even for off-center parts. Built for stability and ease of use, it is a reliable and cost-effective solution for efficient manufacturing.