- Horizontal V Grooving Machine

- Vertical V Grooving Machine

- Automatic Four Side V Grooving Machine

- V Grooving Machine Accessory

- Metal Forming Machine

- Deburring Machine

- Thin Sheet Deburring Machine

- Abrasive Belt Deburring Machine

- Carbon Steel Deburring Machine

- Deburring and Brushing Machine

- Manual Deburring Machine

- Wet Dust Collector

- Deburring Polishing & Brushing Machine

- Deburring & Chamfering Machine

- Wet Deburring & Brushing Machine

- Deburring, Edge rounding & Polishing Machine

- Carbon Steel Deburring & Brushing & Edge rounding Machine

- Dry Deburring, Brushing, and Polishing Machine

- Deburring and Brushing Machine with Slag Hammer Disc

- Shearing Machine

- Press Brake

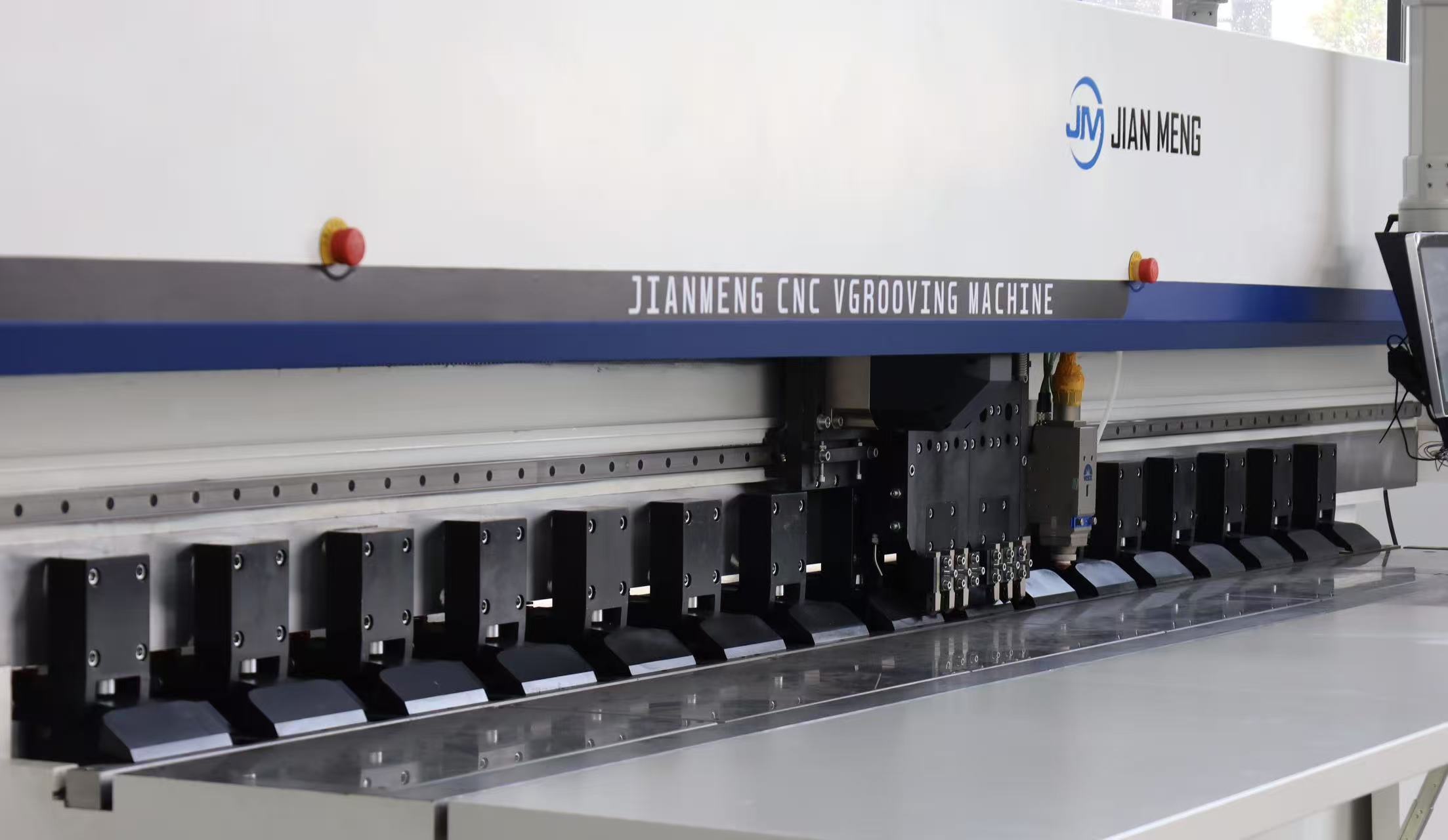

Vertical Laser & V Cutting Machine for Sheet Metal

JIANMENG Laser Cutting Machine integrates high-precision laser cutting, intelligent V-grooving, and fully automated production into one system, enabling one-stop processing from flat sheet to finished workpiece. V Grooving & Laser Integrated Machine achieves positioning accuracy of up to ±0.1 mm, delivering smooth, burr-free, deformation-free edges, and is capable of machining complex irregular shapes and sharp, reflection-free bends. Vertical Laser & V Cutting Machine intelligent control system connects directly to engineering drawings, automatically completing cutting path planning, process parameter matching, and continuous whole-sheet processing. Compared with traditional multi-machine, step-by-step workflows,V Grooving & Laser Integrated Machine boosts efficiency by more than three times, reduces process changeover time by over 80%, and ensures top-tier standards in dimensional accuracy, surface quality, and design complexity—making it the ideal choice for high-end architectural decoration and artistic installations.

Model:GSUM 1500×4000 -3000W

Send Inquiry

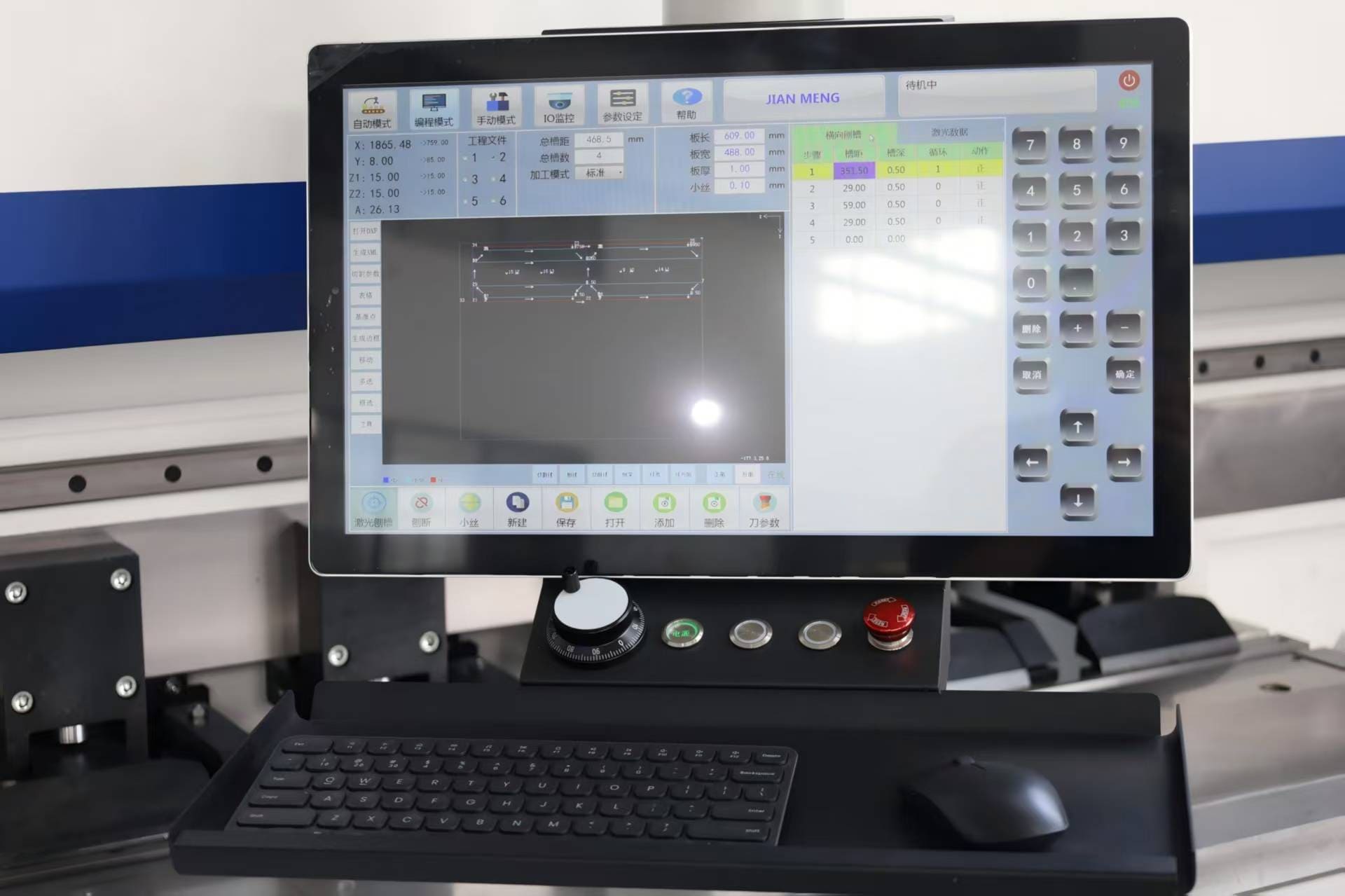

CNC System

The vertical laser & v cutting machine features a 21-inch touch screen that supports both manual input and drawing import, offering a smarter programming method. It displays the working path and real-time position while operating on a full servo control system for enhanced precision and efficiency.

Fiber Laser source

The Fiber Laser source, the core of V Grooving & Laser Integrated Machine, produces a high-energy laser beam by exciting the laser medium to emit a coherent, monochromatic source. Its performance impacts processing accuracy and efficiency. Modern fiber laser generators offer high efficiency, stability, easy maintenance, and long life.

Chiller

A chiller is an industrial cooling system that provides stable chilled water circulation to maintain optimal operating temperatures. It efficiently dissipates heat and controls temperature, extending equipment life and enhancing processing accuracy. Widely used in laser cutting, CNC machining, injection molding, and more, it ensures stable production and equipment safety.

Laser cutting head & v grooving tool holder

The laser cutting head, a key component of laser cutting equipment, is responsible for precisely focusing and directing the laser beam onto the material surface for efficient and accurate cutting. Typically equipped with auto-focus and gas assistance, it ensures process stability and high cut quality, making it widely used in metal processing, electronics, and automotive industries to enhance cutting precision and efficiency. In a V Cutting Machine, the tool holder serves to support and secure the cutting tool, enabling it to cut along a predetermined path during machining. It is usually adjustable to meet various machining requirements, ensuring accuracy and optimal cutting performance.

Fixed Clamp

The function of the fixed clamp on Vertical CNC Grooving Machine is to securely hold the workpiece in place during the milling or slotting process, preventing any movement or shifting. This ensures precise and consistent cuts, improving the accuracy and quality of the machining process.

|

vertical laser & v cutting machine |

Spindle Servo:EASYCAT |

|

Hydraulic control system: Japan Yuken |

|

|

Planetary Gear Reducer:Taiwan AMD/Liming |

|

|

Ground Gear and Rack:Zhejiang BBT |

|

|

AC contacter: Schneider France |

|

|

Bearing: Swedish SKF |

|

|

Alloy knife: JM develop |

|

|

Machine tool cable: Germany Igus |

Vertical Laser & V Cutting Machine Parameter

Working width and length

1500/4000mm-3kW

Thickness range of machinable sheet

0.4-6mm

Maximum shaft speed parallel to X-axis

100m/min

X-axis servo motor power

5.5kW

Axis resolution(X, Y, Z1,Z2,A)

±0.05mm

Axis positioning accuracy(X, Y, Z1, Z2,A)

±0.03mm

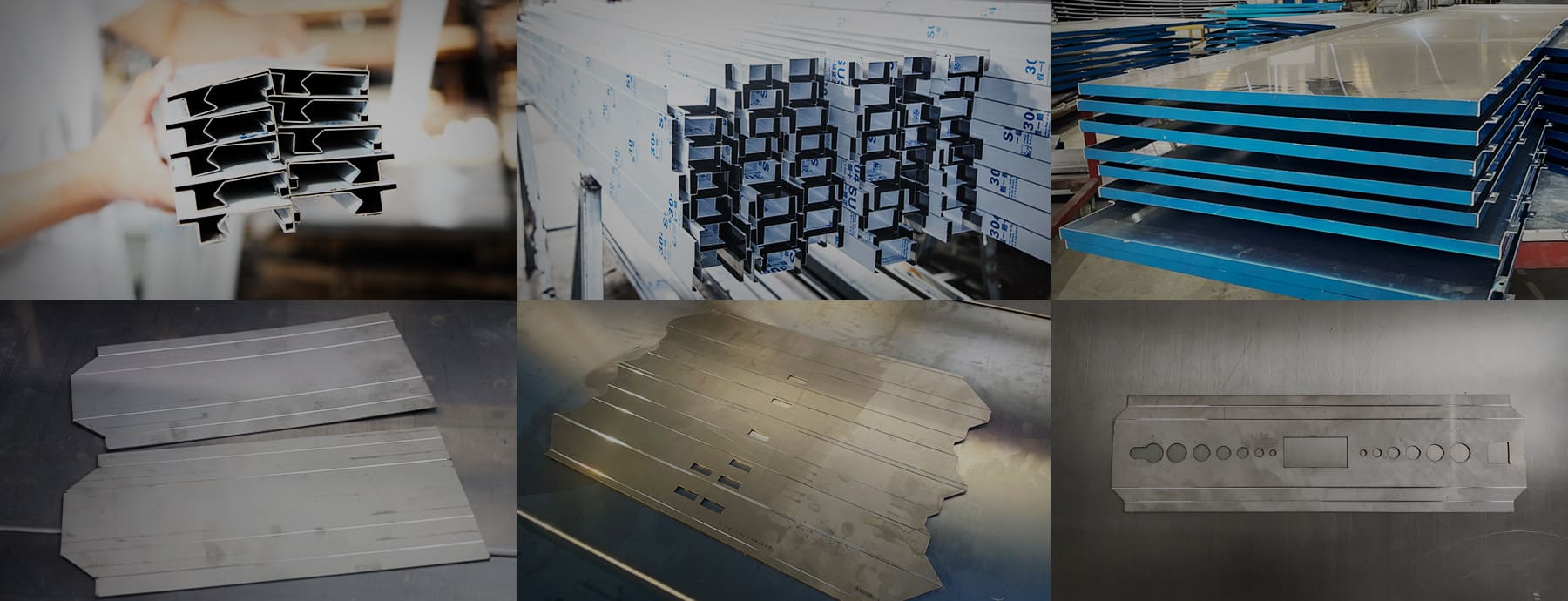

Clients’ Grooving Cases

The laser composite grooving machine combines high-precision laser cutting with intelligent V-grooving technology to achieve efficient processing of sheet metal decorative materials. In a high-end architectural decoration project, this equipment successfully processed complex irregular shapes and sharp bends in metal sheets, significantly improving processing efficiency while ensuring burr-free surfaces and dimensional accuracy of ±0.1mm, meeting designers’ strict requirements for detail and quality.