- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Horizontal V Grooving Machine

- Vertical V Grooving Machine

- Automatic Four Side V Grooving Machine

- V Grooving Machine Accessory

- Metal Forming Machine

- Deburring Machine

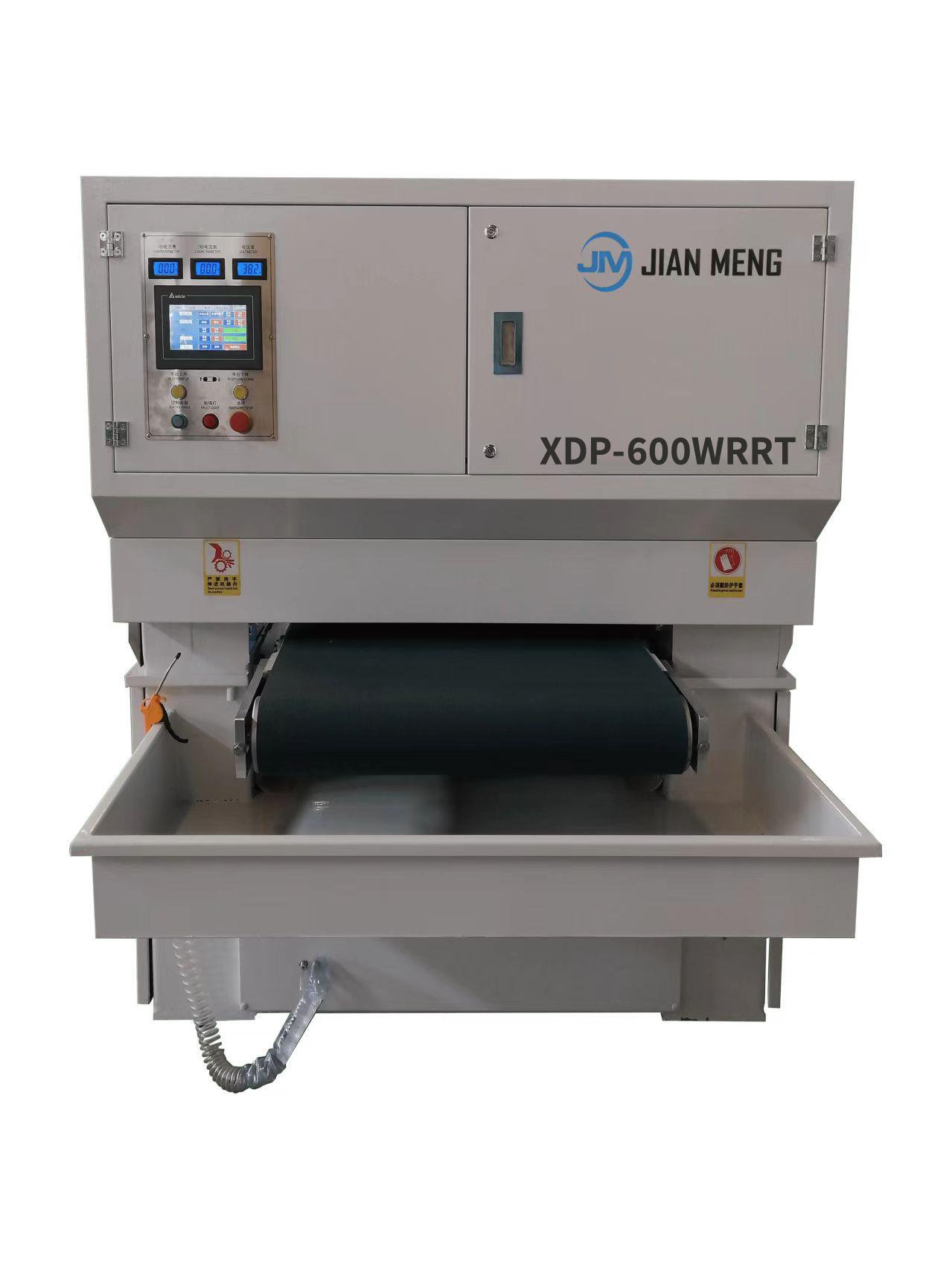

- Thin Sheet Deburring Machine

- Abrasive Belt Deburring Machine

- Carbon Steel Deburring Machine

- Deburring and Brushing Machine

- Manual Deburring Machine

- Wet Dust Collector

- Deburring Polishing & Brushing Machine

- Deburring & Chamfering Machine

- Wet Deburring & Brushing Machine

- Deburring, Edge rounding & Polishing Machine

- Carbon Steel Deburring & Brushing & Edge rounding Machine

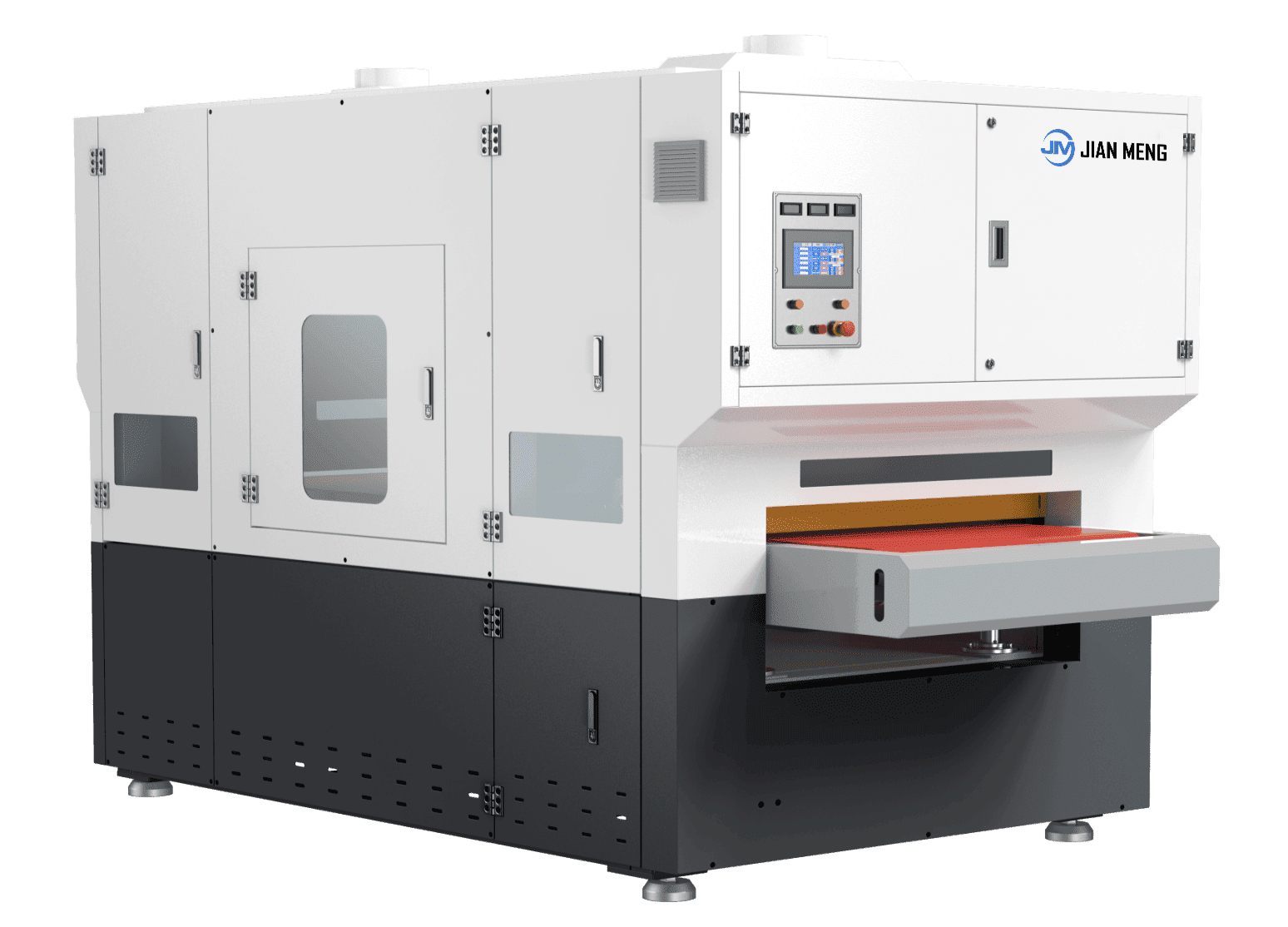

- Dry Deburring, Brushing, and Polishing Machine

- Deburring and Brushing Machine with Slag Hammer Disc

- Shearing Machine

- Press Brake

China Deburring Machine Manufacturers, Suppliers, Factory

- View as

Slag Hammer Discs Deburring Polishing & Brushing Machine

The JM disc-brush deburring machine is designed for metal parts after laser cutting, stamping, or flame cutting. Multiple brush discs work together with wide abrasive belts to complete deburring, edge rounding, slag removal, and surface smoothing in a single pass. This creates softer edges and a finer, more uniform finish, enhancing the visual quality and added value of stainless steel, carbon steel, and aluminum workpieces. With a high-rigidity frame and optimized mechanical structure, the machine maintains consistent performance even during long hours of operation. The intelligent control system makes operation simple—brush pressure and processing intensity can be freely adjusted to match different processes. Its wet dust-removal system greatly reduces dust hazards, keeping the worksp......

Read MoreSend InquiryManual metal sheet deburring machine

JM manual deburring machine is primarily used for removing burrs from the surface of metal workpieces. Due to its design and operation, the machine is suitable for fine surface deburring and polishing. The manual deburring machine effectively removes surface burrs, ensuring smooth and safe workpieces. It is widely used in sheet metal workpieces for medical devices, kitchenware, refrigerators, and other similar applications. JM manual deburring machine excels in surface deburring of metal workpieces. If your focus is on achieving smooth and high-quality surfaces, it provides an efficient and precise solution.

Read MoreSend InquiryCNC Deburring, Brushing & Polishing Machine for metal sheet

JM is a premier manufacturer committed to delivering cutting-edge solutions in metal surface finishing. Our advanced deburring, polishing, and brushing systems combine efficiency, precision, and intelligence—integrating deburring, polishing, oxide removal, chamfering, and surface brushing into a single, seamless process. Designed for the demanding needs of sheet metal fabrication, automotive components, and precision instrument industries, JM’s Industrial Deburring Machines ensure perfectly smooth, safe edges on stainless steel, carbon steel, aluminum, and copper. With outstanding performance in efficiency, stability, and smart control, our automatic systems help manufacturers enhance product quality, maintain consistency, and accelerate production—offering a dependable, all-in-one s......

Read MoreSend InquiryCNC Wet Metal Deburring & Brushing & Polishing Machine

JM Wet Deburring Machine is a high-performance solution designed to efficiently remove burrs, slag, oxide layers, and sharp edges from metal sheets and plates. Utilizing wide abrasive belts in a wet processing environment, it delivers smooth, consistent surface finishes while eliminating harmful dust emissions. This makes it especially effective for post-processing after laser cutting, plasma cutting, or shearing. Equipped with a dual abrasive belt system, the machine ensures fast and uniform material removal across large surfaces. The wet grinding process not only cools the metal during operation—preventing heat-related distortion—but also extends the life of consumables. Its integrated filtration and water recirculation system supports clean, low-maintenance operation. Engineered for m......

Read MoreSend InquiryCNC Carbon Steel Deburring &Brushing& Edge roundingBrushing Machine

The deburring and chamfering machine is specifically designed for surface treatment of carbon steel components. Automatic Deburring Machine features an innovative combination of three sets of wide abrasive belts and six universal rotary brushes for chamfering. This design ensures efficient and precise removal of surface burrs while achieving edge chamfering and surface brushing, significantly improving the surface quality and appearance of the workpiece. The Deburring & Brushing&edge rounding Machine meets the precision and quality requirements of carbon steel surface treatment across various industries, enhancing both production efficiency and product value. Parameters can be adjusted according to different processing needs, and suitable abrasives can be selected accordingly. The me......

Read MoreSend InquiryCNC Deburring, Chamfering & Polishing Machine

JM, a trusted manufacturer, has developed the advanced RPT series of deburring, polishing, and brushing machines to meet the highest standards of modern metal finishing. This versatile machine combines abrasive belt deburring, universal roller brush chamfering, and polishing and brushing finishing into a single, efficient process, providing a comprehensive surface treatment solution. The RPT machine is widely used in sheet metal fabrication, automotive parts production, precision instrument manufacturing, and other industries where edge quality and surface finish are critical. It reliably removes burrs, sharp edges, and irregularities from stainless steel, carbon steel, aluminum, copper, and various other metals, resulting in a smooth, secure, and fine finish. Designed for high perfo......

Read MoreSend Inquiry