- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

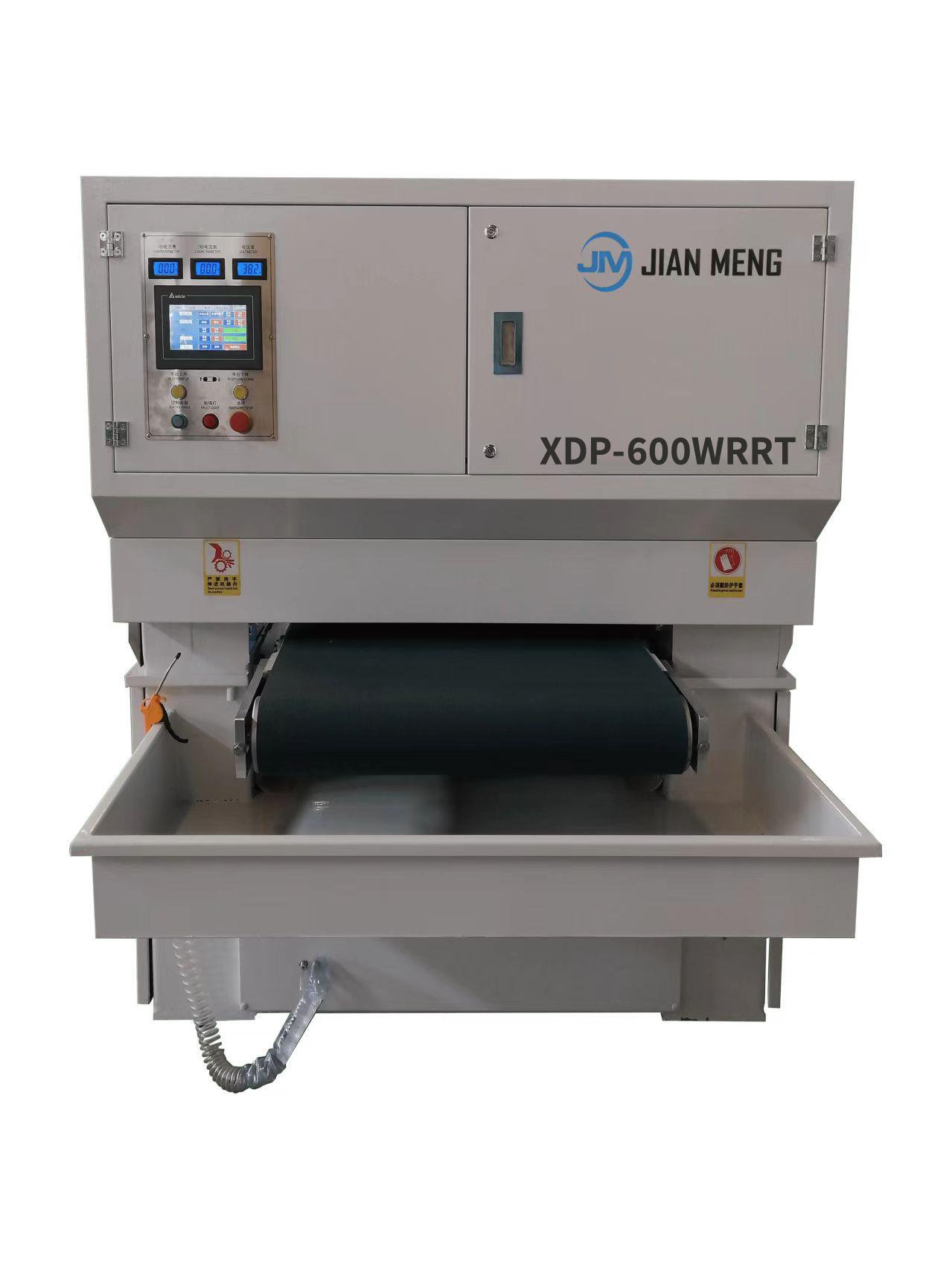

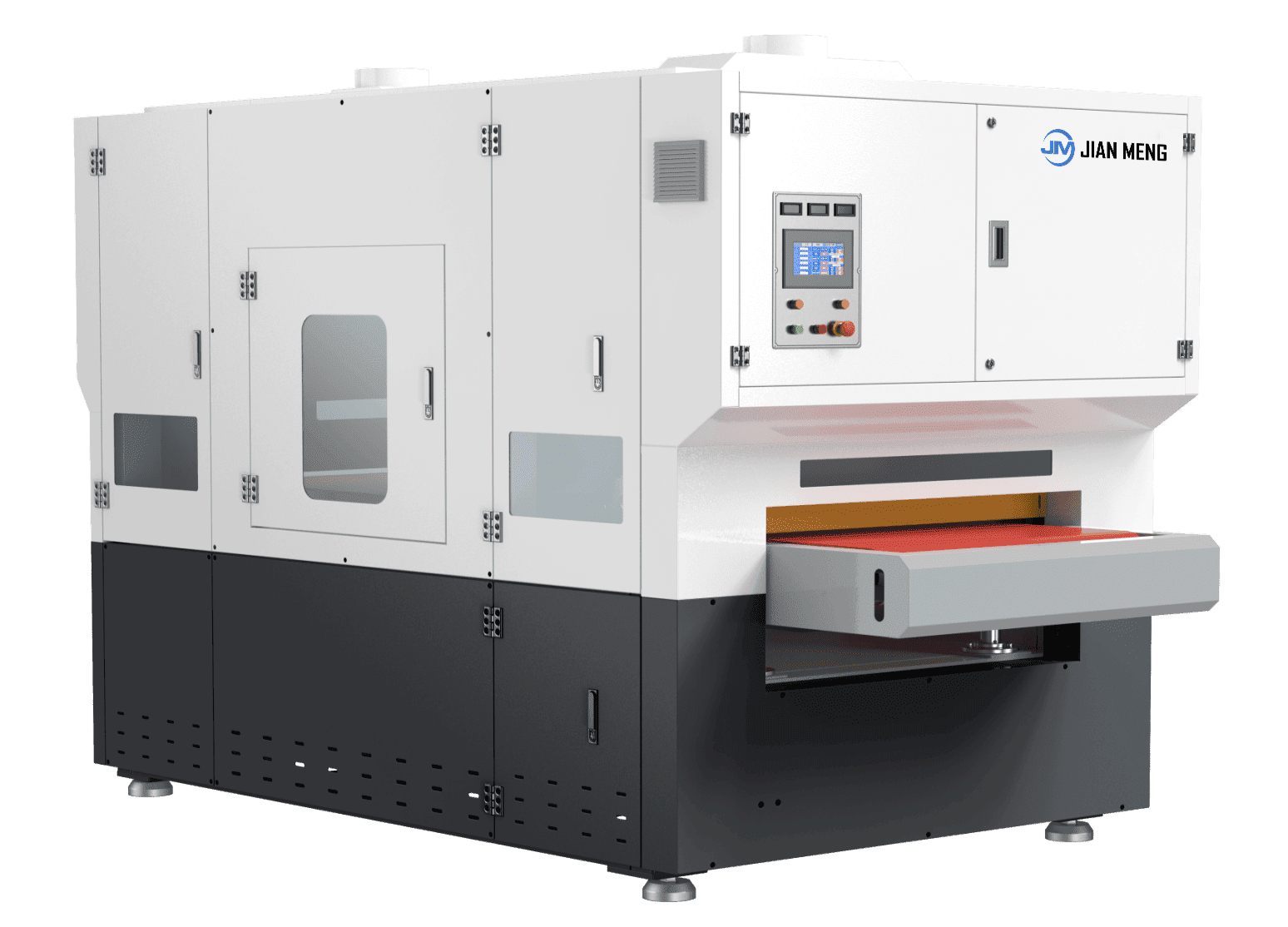

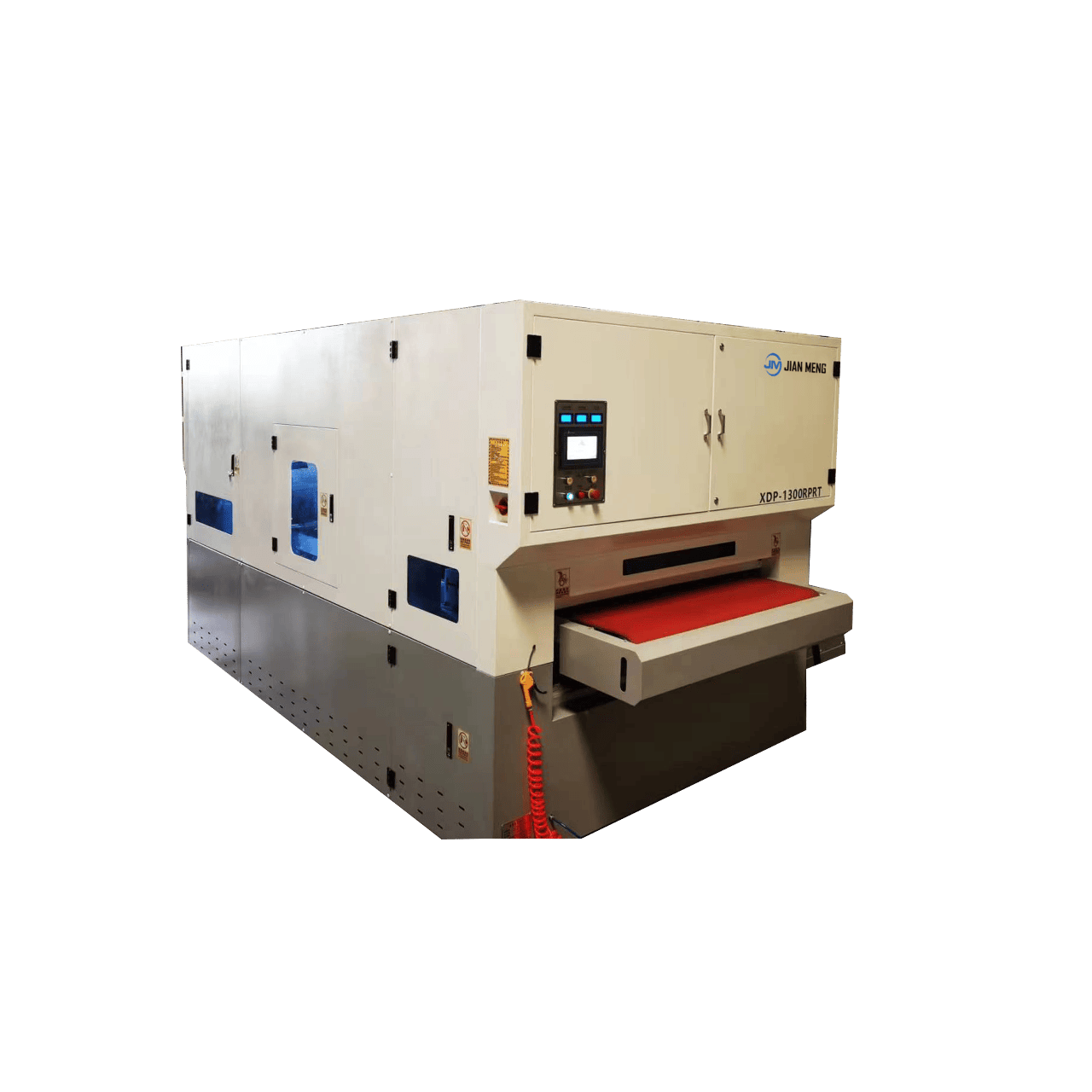

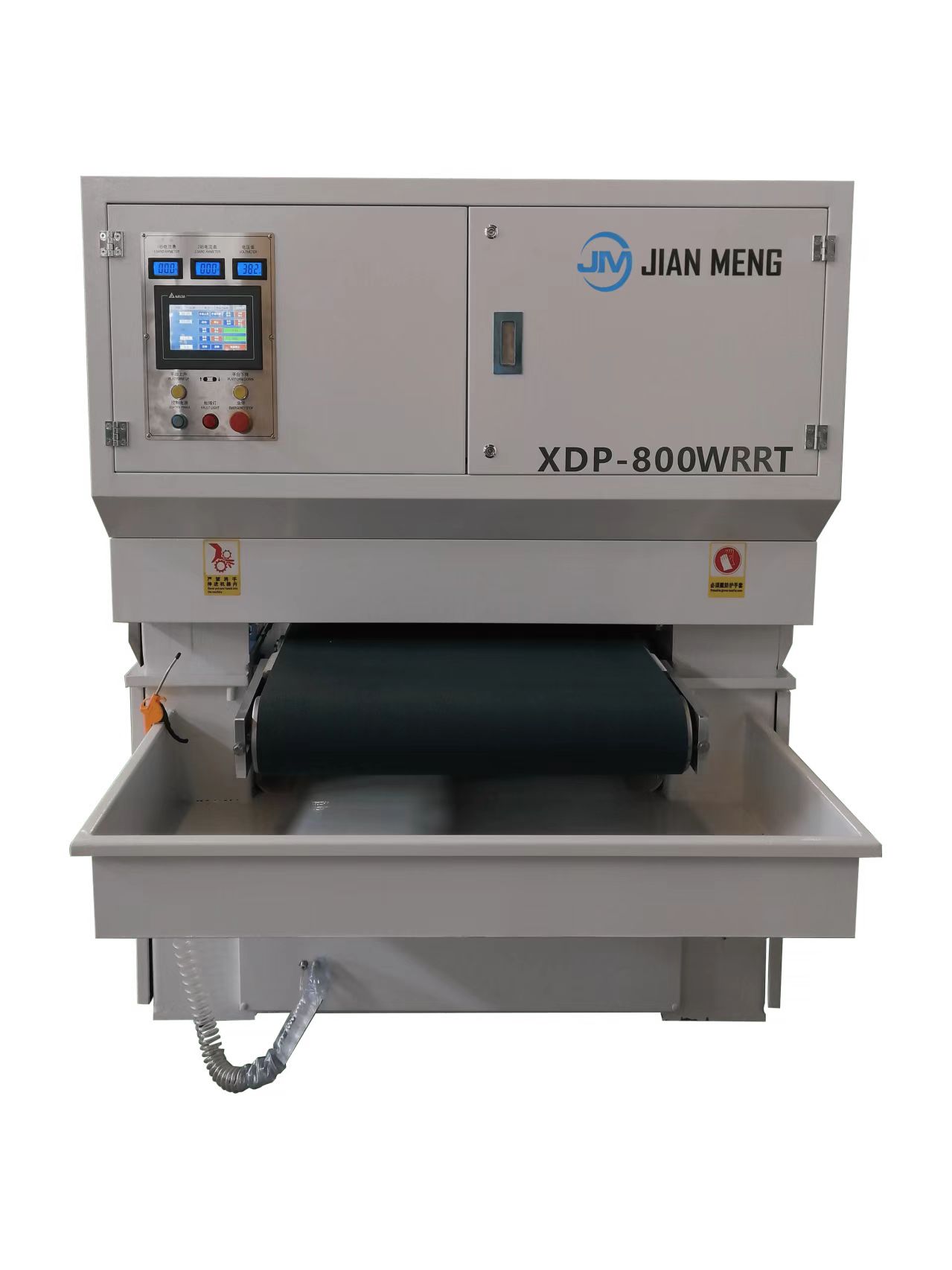

China Automatic Deburring Machine Manufacturers, Suppliers, Factory

Our commission is to serve our buyers and purchasers with most effective good quality and aggressive portable goods for Automatic Deburring Machine,Deburring Machine,Metal Deburring Machine,CNC Deburring Machine,Industrial Deburring Machine, Our experienced specialized group will be wholeheartedly at your support. We sincerely welcome you to check out our site and enterprise and send out us your inquiry.

Automatic Deburring Machine, Being guided by customer demands, aiming at improving the efficiency and quality of customer service, we constantly improve products and provide more comprehensive services. We sincerely welcome friends to negotiate business and start cooperation with us. We hope to join hands with friends in different industries to create a brilliant future.

Hot Products

Vertical High Speed V Cutting Machine For Stainless Steel Plates

The manufacturer JM in China is one of professional manufacturer and exporter of Vertical High Speed V Cutting Machine For Stainless Steel Plates. The vertical high speed V cutting machine for stainless steel plates is an upgraded product of traditional grooving machine.Vertical High Speed V Slotting Machine

The V grooving machine manufacturer JM in China not only has excellent vertical high speed V slotting machine, bust also can provide the full range of service. From the project planning and starting, to production tracking and operation training, to equipment maintenance, spare parts supply and maintenance.Vertical Back And Forth Cutting Machine

The V cutting machine manufacturer JM in China produces the excellent vertical back and forth cutting machine. The vertical back and forth cutting machine combines with all characteristics of traditional models.CNC Vertical Back And Forth V Groove Cutting Machine

The leading V cutting machine manufacturer and supplier JM in China has the most types of V grooving machines, the CNC vertical back and forth V groove cutting machine from it is equipped with simple and intelligent system.Four Side CNC V Grooving Machine

JM is a leading China Four Side CNC V Grooving Machine manufacturer. A metal sheet v grooving machine can create V-shaped grooves in stainless steel sheets, aluminum sheets, composite aluminum sheets, copper sheets, and other metal plates. Four side v grooving machine realize the horizontal grooving of the plate. This allows the bent workpieces to have a very small edge radius, meeting the high precision and aesthetic demands of the high-end sheet metal decoration industry. JIANMENG provides various solutions, making metal fabrication easier!Electro-Hydraulic CNC Press Brake

The Press Brake is an advanced and intelligent sheet metal forming solution engineered to accommodate a wide range of fabrication requirements. Its structural design, developed by JIANMENG Smart, incorporates PRO/E 3D modeling and finite element analysis (FEA) to optimize frame strength and rigidity in compliance with international standards. Constructed from high-quality Q235B steel, the frame undergoes shot blasting, anti-corrosion coating, and vibration stress-relief treatment to enhance mechanical stability, durability, and long-term performance.