- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Horizontal V Grooving Machine

- Vertical V Grooving Machine

- Automatic Four Side V Grooving Machine

- V Grooving Machine Accessory

- Metal Forming Machine

- Deburring Machine

- Thin Sheet Deburring Machine

- Abrasive Belt Deburring Machine

- Carbon Steel Deburring Machine

- Deburring and Brushing Machine

- Manual Deburring Machine

- Wet Dust Collector

- Deburring Polishing & Brushing Machine

- Deburring & Chamfering Machine

- Wet Deburring & Brushing Machine

- Deburring, Edge rounding & Polishing Machine

- Carbon Steel Deburring & Brushing & Edge rounding Machine

- Dry Deburring, Brushing, and Polishing Machine

- Deburring and Brushing Machine with Slag Hammer Disc

- Shearing Machine

- Press Brake

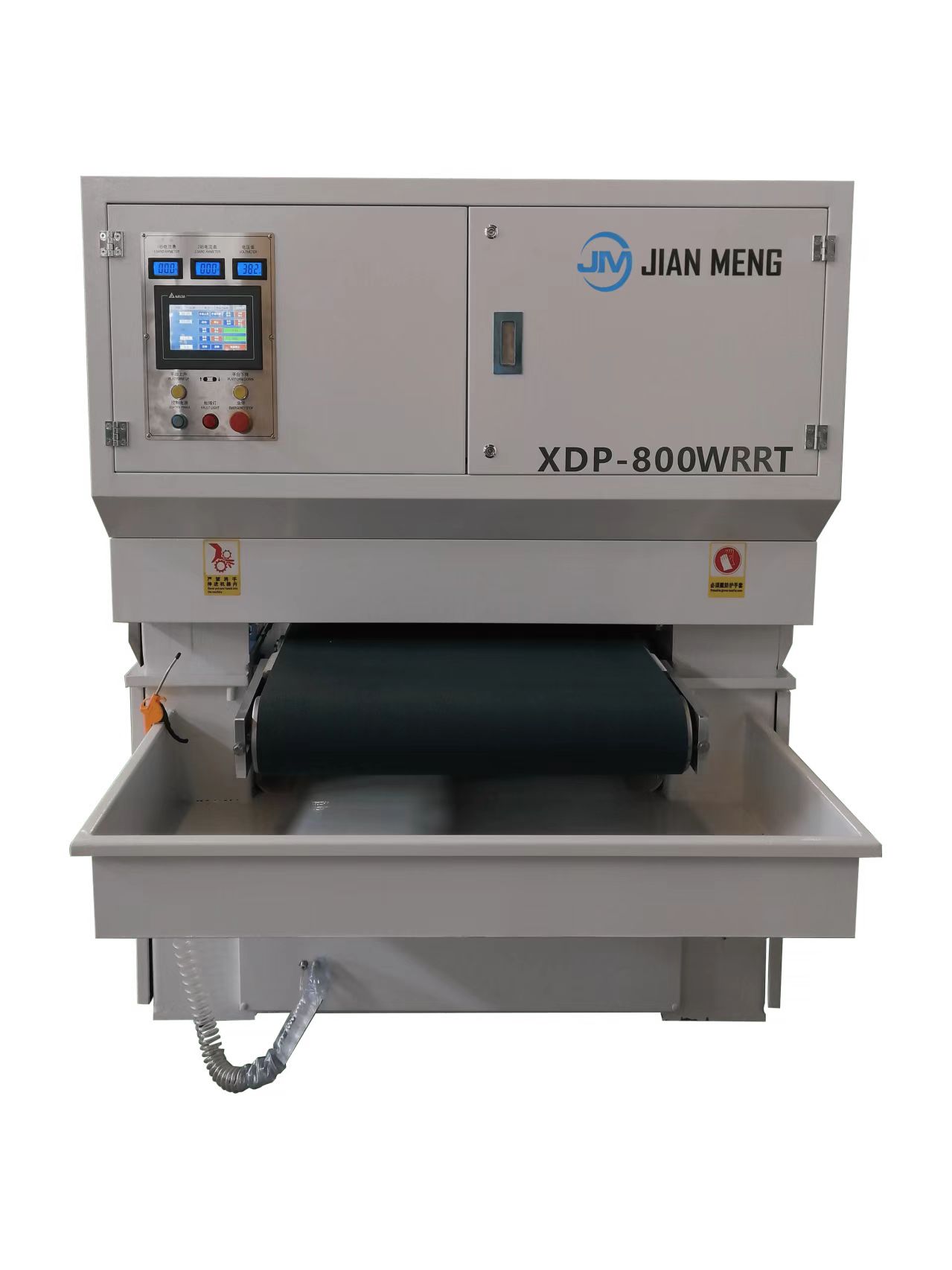

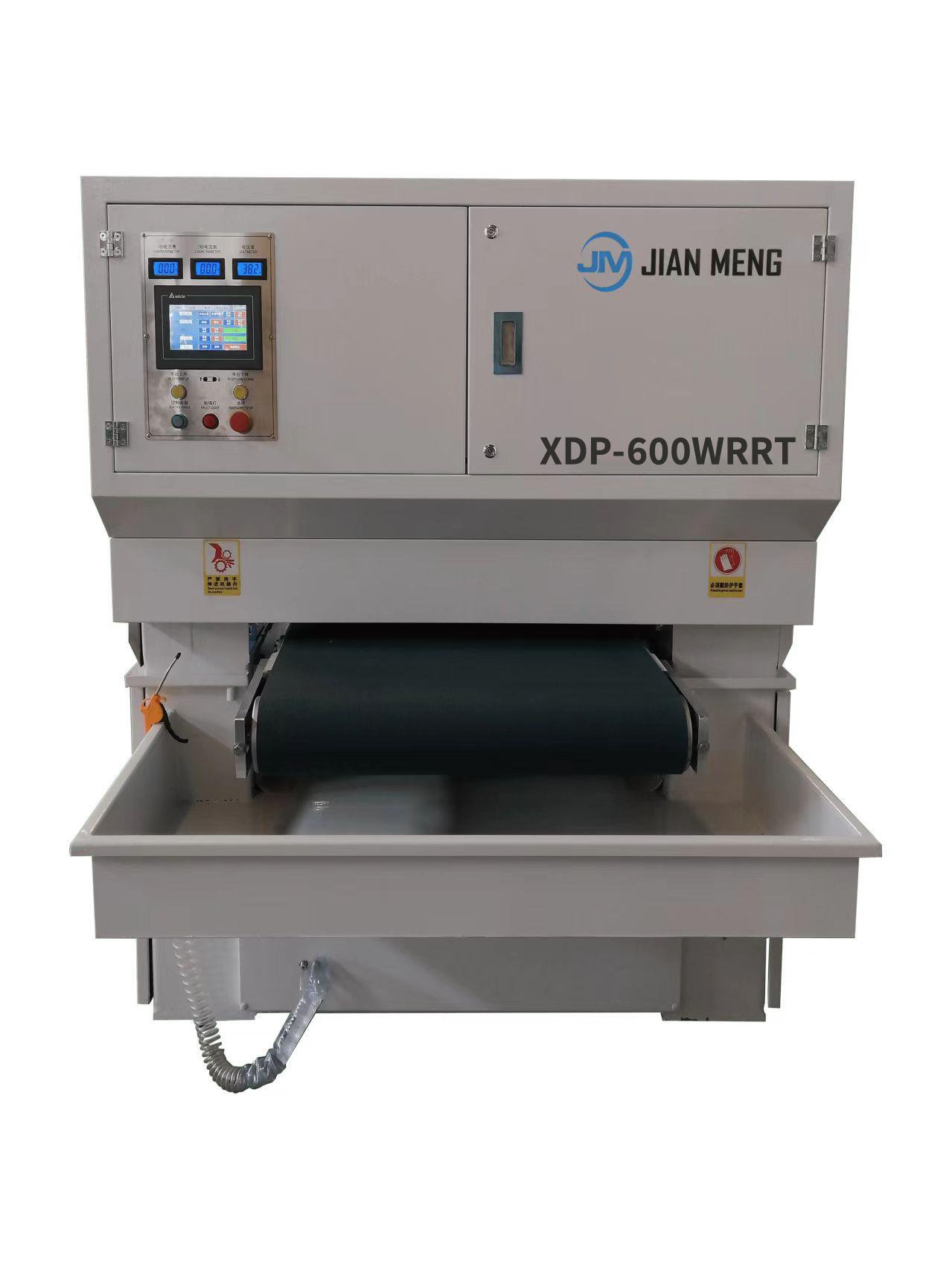

Wet Deburring & Brushing Machine

JM Wet Deburring Machine is a specialized solution for removing burrs, slag, oxide layers, and sharp edges from metal sheets and plates. It operates using wide abrasive belts under wet conditions, ensuring clean, uniform surface finishing without producing harmful dust. This machine is ideal for improving surface quality after laser, plasma, or shear cutting. Featuring a dual abrasive belt structure, the metal finishing machine delivers high-speed, consistent material removal across a wide working width. Automatic deburring machine process cools the material during grinding, prevents thermal deformation, and enhances the lifespan of consumables. Its built-in filtration and water circulation system ensures clean operation and easy maintenance. Suitable for stainless steel, aluminum, copper, the deburring equipment for metal sheet is widely used in industries such as kitchenware, electronics, and general metal fabrication. Compared to dry processing, it offers superior surface results, improved workplace safety, and a more environmentally friendly production process.

Model:XDP-600WRR

Send Inquiry

Deburring Machines

Perfect Deburring: Wet deburring machine is a piece of equipment used for surface treatment of workpieces.

It primarily utilizes water or other liquid media in combination with abrasive materials to perform deburring, oxide removal, edge trimming, polishing, and other finishing processes. Compared to dry deburring methods, it offers a cleaner operation, better surface finish, and enhanced environmental performance.

Main configuration list

PCL touch screen (7-inch): Delta

Abrasive belt motor (7.5kw): Huarui

Conveyor Motor (1.5 kW) : Jinwanshun

Platform Servo Lifting Motor (1 kW): Xinshida

Water Pump Motor (0.55 kW)– Zhejiang Lanbang

Touchscreen: Delta

Control buttons:Schneider (France)

Solenoid valve:Airtac

Pneumatic components:Mobang

CNC Display Screen

The CNC display screen of the deburring machine is a key component of the equipment, responsible for centrally displaying and controlling all operation parameters during the deburring process, improving processing efficiency and precision. The CNC display not only provides real-time feedback but also allows the operator to make precise parameter adjustments according to the needs, ensuring the quality of the workpiece.

Consumables

Abrasive Belt

The deburring and brushing system of this machine adopts a wide-format abrasive belt structure. The belts are arranged longitudinally across the full width and utilize our patented technology for automatic belt tracking and flat surface polishing along metal edges. This allows for high-precision brushing and efficient removal of tough burrs such as those caused by punching or shearing. The abrasive belts are easy and quick to replace, ensuring smooth operation and minimal downtime.

Comparison of Before and After Deburring

Before deburring:

Workpieces often exhibit burrs, sharp edges, or protruding fins as a result of cutting, stamping, milling, sawing, or drilling. These imperfections can be accompanied by surface oxides, welding slag, oil stains, or other contaminants. Such defects not only compromise the surface quality but may also interfere with subsequent processing steps like coating, welding, or assembly.

After Deburring:

Following the deburring process, the workpiece surface becomes smooth, clean, and free of burrs and sharp edges. All irregular projections and sharp corners generated during manufacturing are effectively removed. Edges are more uniform and rounded, minimizing the risk of injury, reducing wear on tooling, and ensuring better performance and compatibility in downstream operations.

XDP-600 WRR Machine Parameter

|

Worktable width |

600mm |

|

Maximum load capacity |

150kg |

|

Processing thickness |

1-80mm |

|

Minimum processing size |

(non-perforated plate) 300*50*1mm |

|

Abrasive belt size |

1900*650 mm |

|

Machine Weight |

2800kg |

|

Dimensions |

2500 *1800 * 2200 mm |

Clients’ Deburring Cases

A client of ours from Malaysia specializes in manufacturing aluminum and copper connectors for power systems. Due to the low melting points of aluminum and copper, the company introduced the WRR Wet Deburring Machine. With its dual abrasive belt structure and water-cooling system, the machine effectively solved the issue of thermal damage and enabled efficient, low-temperature processing. The resulting surfaces are smooth and free of oxidation, greatly improving product consistency and yield. At the same time, the cleaner workshop environment has been highly appreciated by the customer.