- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Horizontal V Grooving Machine

- Vertical V Grooving Machine

- Automatic Four Side V Grooving Machine

- V Grooving Machine Accessory

- Metal Forming Machine

- Deburring Machine

- Thin Sheet Deburring Machine

- Abrasive Belt Deburring Machine

- Carbon Steel Deburring Machine

- Deburring and Brushing Machine

- Manual Deburring Machine

- Wet Dust Collector

- Deburring Polishing & Brushing Machine

- Deburring & Chamfering Machine

- Wet Deburring & Brushing Machine

- Deburring, Edge rounding & Polishing Machine

- Carbon Steel Deburring & Brushing & Edge rounding Machine

- Dry Deburring, Brushing, and Polishing Machine

- Deburring and Brushing Machine with Slag Hammer Disc

- Shearing Machine

- Press Brake

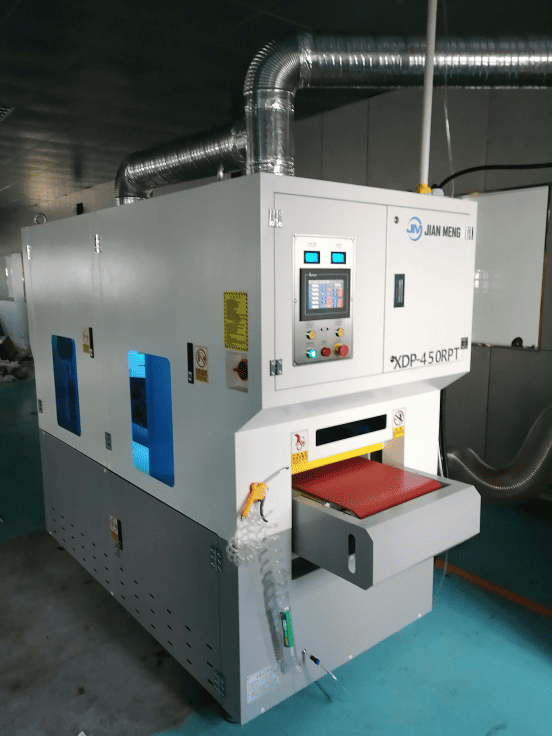

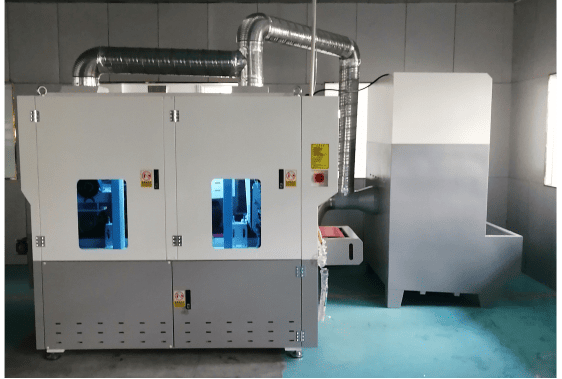

CNC Deburring, Edge rounding & Polishing Machine

JM is a leading manufacturer specializing in the production of advanced RPT Deburring, Polishing & Brushing Machines, designed to meet the highest standards of modern metal surface processing. This highly efficient and intelligent equipment integrates abrasive belt deburring, universal roller brush chamfering, and polishing roller brushing into one process, providing an all-in-one solution for surface finishing. The RPT Machine is widely applied in sheet metal fabrication, automotive parts manufacturing, precision instrument production, and other industries that require superior edge and surface quality. It effectively removes burrs, sharp edges, and surface irregularities from stainless steel, carbon steel, aluminum, copper, and other metals, ensuring smooth, safe, and refined surfaces. Engineered for high efficiency, stability, and intelligent operation, the RPT Machine not only enhances the aesthetic and functional quality of workpieces but also improves consistency and production efficiency. It offers manufacturers a reliable, versatile, and comprehensive surface treatment solution. Whether your goal is to achieve higher product quality or streamline processing efficiency, the JM RPT Deburring, Polishing & Brushing Machine is the indispensable choice for enterprises aiming for excellence in metal surface finishing.

Model:XDP-450RPT

Send Inquiry

Deburring Machines

Perfect Deburring: The XDP-450RPT Deburring Polishing & Brushing Machine efficiently processes the edges of metal parts, sheets, and plates by removing rough burrs and sharp edges left behind during manufacturing, ensuring a smooth, safe, and high-quality surface finish. In addition to edge treatment, the machine effectively eliminates oxide layers and heat-affected zones from metal surfaces after welding, significantly improving the adhesion of coatings and paints. This comprehensive surface preparation makes it an essential tool for enhancing both the appearance and performance of metal components across various industrial applications.

Main configuration list

PCL touch screen(7-inch): Delta

Abrasive belt motor(5.5kW): Huarui

Roller brush self-rotation motor(2.2kW): Huarui

Roller brush orbital motor (1.1kW):Jinwanshun

Vacuum suction fan (7.5kW):Jiuzhou Puhui

Control buttons:Schneider (France)

Solenoid valve:Airtac

Pneumatic components:Mobang

CNC Display Screen

The CNC display screen serves as the central control hub of the deburring machine, presenting all operational parameters in a clear and integrated interface. It enables real-time monitoring and precise adjustments during processing, helping operators optimize settings for different requirements. By enhancing both efficiency and accuracy, the CNC display ensures stable operation and guarantees the high-quality finish of every workpiece.

Internal Structure

The internal structure of the 450RPT consists of one set of abrasive belts + four roller brushes + one polishing roller, forming processing system. The first abrasive belt is used for the initial removal of burrs from the workpiece surface; the second stage with four roller brushes performs brushing treatment, ensuring thorough deburring without damaging the surface; and finally, the polishing roller carries out precision polishing, making the surface smooth, uniform, and visually refined. With its well-designed structure, the Metal Finishing Machine enables efficient, stable, and continuous surface treatment.

Consumables

Abrasive Belt

Abrasive belts are widely used as abrasive tools for metal surface treatment. After undergoing special processing, they are formed into a belt structure, suitable for various tasks such as grinding, deburring, polishing, finishing, and wire drawing. The abrasive belt removes excess material through friction with the workpiece surface, improving the surface quality and appearance of the workpiece.

Roller brushes

The roller brush is an efficient tool used in metal processing and surface treatment, widely applied in deburring, surface brushing, cleaning, and removing oxide layers and oil stains. Its working principle is to make contact between the rotating bristles and the workpiece surface, achieving deburring, chamfering, and surface finishing.

Comparison of Before and After Deburring

Before deburring:

Workpieces often exhibit burrs, sharp edges, or protruding fins as a result of cutting, stamping, milling, sawing, or drilling. These imperfections can be accompanied by surface oxides, welding slag, oil stains, or other contaminants. Such defects not only compromise the surface quality but may also interfere with subsequent processing steps like coating, welding, or assembly.

After Deburring:

Following the deburring process, the workpiece surface becomes smooth, clean, and free of burrs and sharp edges. All irregular projections and sharp corners generated during manufacturing are effectively removed. Edges are more uniform and rounded, minimizing the risk of injury, reducing wear on tooling, and ensuring better performance and compatibility in downstream operations.

XDP-450RPT Machine Parameter

|

Worktable width |

450mm |

|

Maximum load capacity |

150kg |

|

Processing thickness |

1-90mm |

|

Minimum processing size |

(non-perforated plate) 50*50*0.5mm |

|

Abrasive belt size |

1650*450mm |

|

Polishing roller size |

Φ200*450mm |

|

Roller brush size |

150*250*25 mm |

Clients’ Deburring Cases

A leading manufacturer specializing in stainless steel components faced challenges with inconsistent edge finishing, low processing efficiency, and poor surface preparation that affected coating and paint adhesion. After adopting the JM Deburring Polishing & Brushing Machine, the company experienced a significant increase in production efficiency, enhanced edge consistency, and improved surface quality—particularly in removing weld oxidation and heat-affected zones. The intelligent, automated system also reduced manual labor and improved overall process stability.