China Industrial Deburring Machine Manufacturers, Suppliers, Factory

We support our consumers with ideal good quality merchandise and large level provider. Becoming the specialist manufacturer in this sector, we have attained wealthy practical encounter in producing and managing for Industrial Deburring Machine,Deburring Machine,Metal Deburring Machine,CNC Deburring Machine,Automatic Deburring Machine, We hope we can have a friendly relationship with businessman from all over the world.

Industrial Deburring Machine, After years' creating and developing, with the advantages of trained qualified talents and rich marketing experience, outstanding achievements were gradually made. We get good reputation from the customers due to our good solutions quality and fine after-sale service. We sincerely wish to create a more prosperous and flourishing future together with all the friends home and abroad!

Hot Products

CNC Vertical High Speedv Grooving Machine

The Chinese V grooving machine manufacturer JM has the most types of CNC Vertical High Speedv Grooving Machine. Its CNC vertical high speed V grooving machine is efficient during mirror plates processing.Vertical High Speed V Groove Cutting Machine

The V grooving machine manufacturer JM in China is professional and durable, its vertical high speed V groove cutting machine is the best choice, when there is a need to process the mirror plate.Automatic Four Side V-shaped Grooving Machine

JM as a professional automatic four side v-shaped grooving machine manufacturer in China, it offers high energy efficiency automatic four side V -shaped grooving machine. This machine can play an important role in rigid boxes processing.CNC Automatic Four Side V Grooving Machine

JM is a leading China CNC Automatic Four Side V Grooving Machine manufacturers. The professional V grooving machine manufacturer JIANMENG has a standardized rack production work shop, with technological innovation as its core advantage. The CNC automatic four side V grooving machine form it is equipped with simple and intelligent system, easy to operate, easy to learn and understand.CNC Carbon Steel Deburring Machine

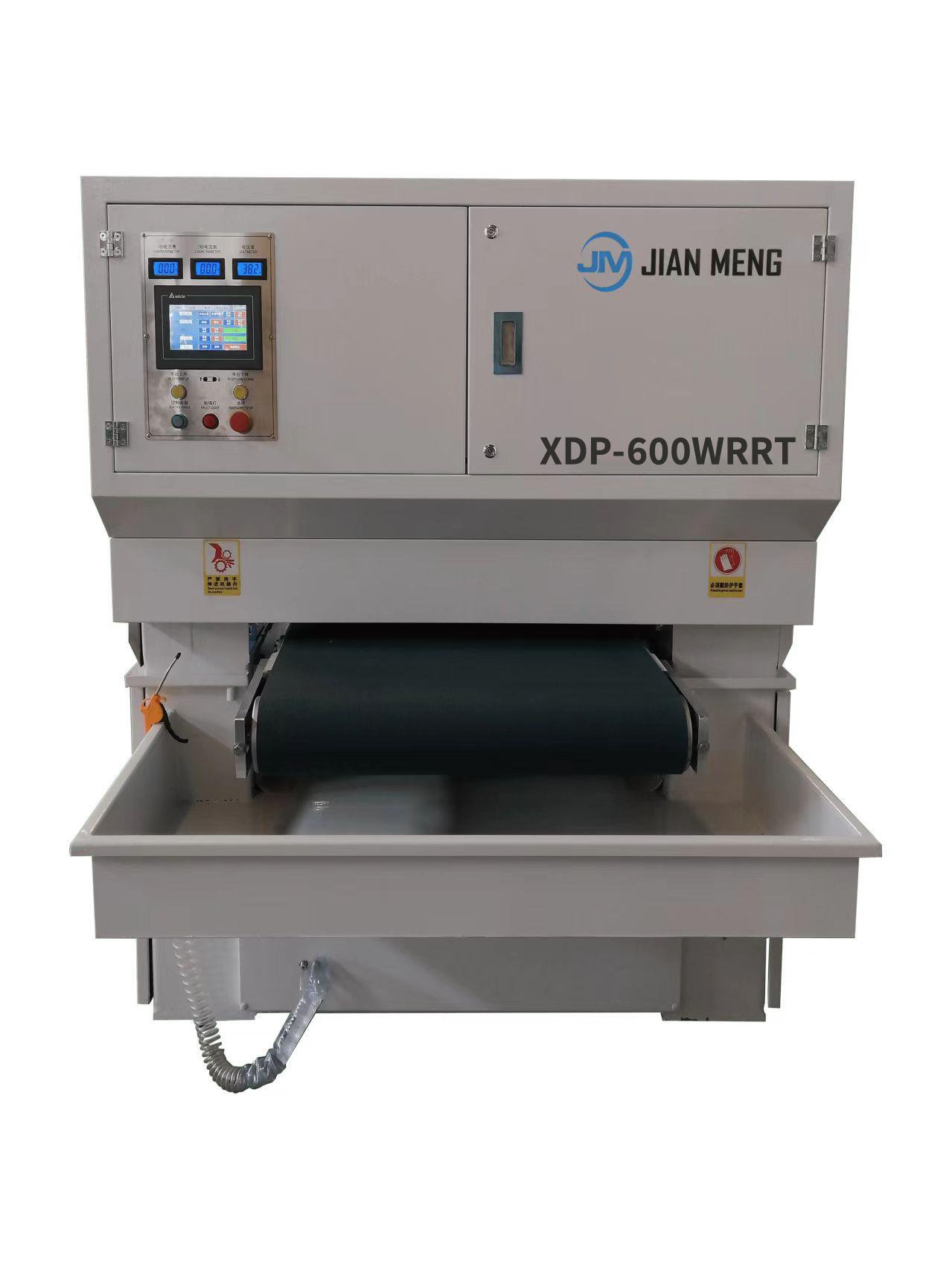

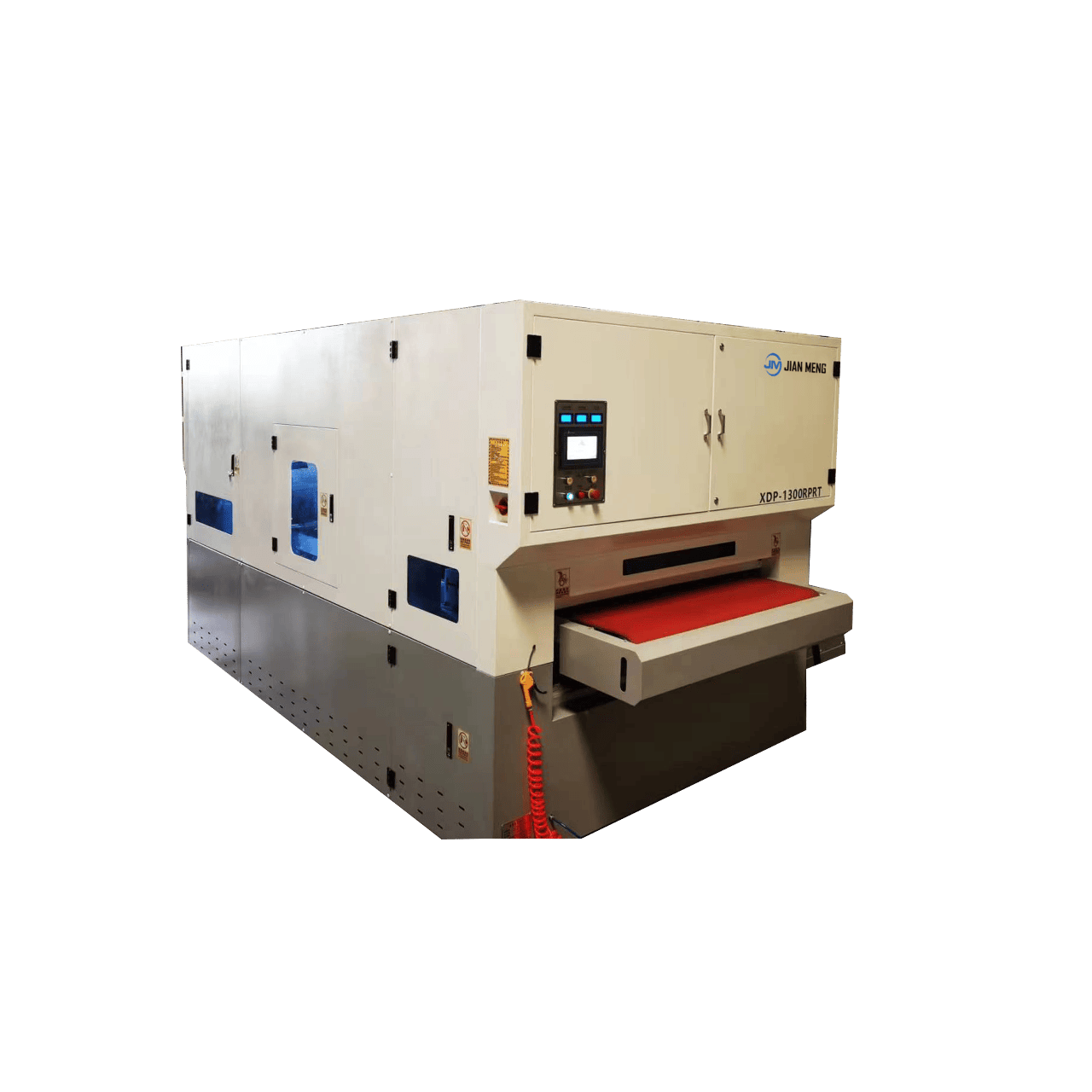

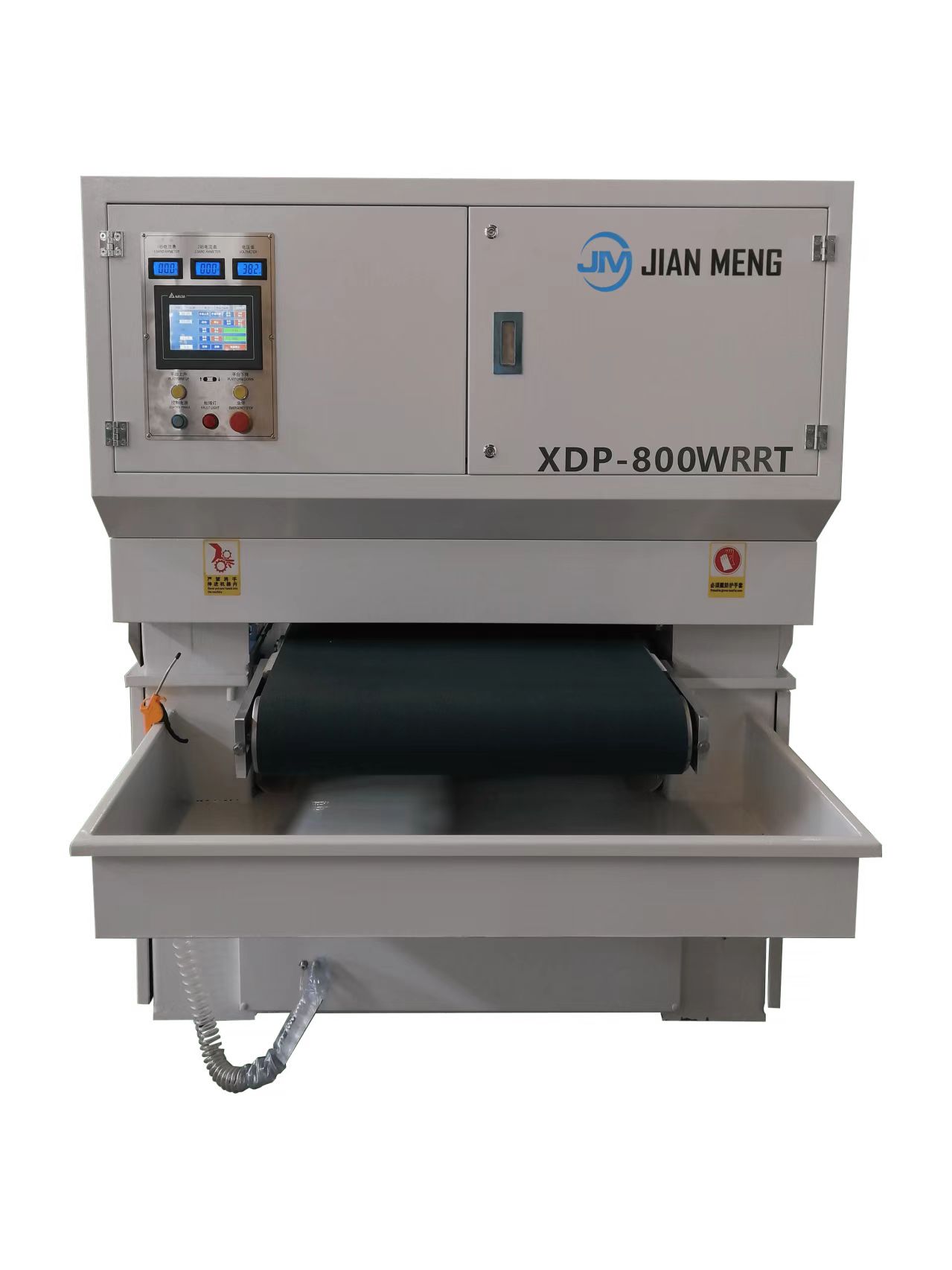

JM is a leading manufacturer specializing in CNC Carbon Steel Deburring Machine. The Carbon Steel Deburring machine is an industrial device specifically designed for removing burrs, sharp edges, and oxide layers from carbon steel parts, plates, and workpieces. Deburring Machine for Carbon Steel Plates is widely used in metal processing, machinery manufacturing, automotive components, Carbon Steel Structure, shipbuilding, and electrical cabinets. JM Carbon Steel Deburring Machine is an efficient deburring, chamfering, and surface finishing equipment specially designed for carbon steel workpieces. It combines advanced technology and high-quality craftsmanship to significantly improve production efficiency while ensuring processing accuracy. Whether used for cutting, stamping, or laser-processed workpieces, the JM Carbon Steel Deburring Machine provides excellent deburring results and ensures that the surface of the workpieces is smooth and flat.CNC Thin Sheet Deburring Machine

JM is a leading manufacturer specializing in CNC Thin Sheet Deburring Machine.The deburring machine is primarily used for deburring and chamfering the surfaces of various metal workpieces to improve surface quality. The JM deburring machine combines two functions: abrasive belt deburring and roller brush chamfering, allowing multiple surface processing steps to be completed in a single operation, thus enhancing production efficiency and product quality stability. It is suitable for materials such as stainless steel, aluminum alloy plates, steel plates, and copper plates. Different parameters can be adjusted, and appropriate abrasives can be selected based on processing requirements. JM Thin Sheet Deburring Machine, with its high efficiency, stability, and intelligent features, provides a one-stop surface treatment solution for metal processing enterprises. Whether it is improving workpiece quality or enhancing production efficiency, this machine meets all processing demands, making it an essential piece of equipment for modern manufacturing.