- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Sheet Metal Cutting Manufacturers, Suppliers, Factory

We purpose to understand high quality disfigurement with the output and supply the top service to domestic and overseas buyers wholeheartedly for Sheet Metal Cutting,Shearing Machine for Carbon Steel,Shearing Machine for Aluminum Sheet,Shearing Machine for Construction Industry,Sheet Metal Shearing Machine, Seeing believes! We sincerely welcome the new prospects abroad to set up company interactions and also expect to consolidate the interactions with all the long-established clients.

Sheet Metal Cutting, We rely on high-quality materials, perfect design, excellent customer service and the competitive price to win the trust of many customers at home and abroad. 95%products are exported to overseas markets.

Hot Products

CNC Horizontal High Speed V Groove Slotting Machine

The Chinese manufacturer JM has the most types of V grooving machines in China, the CNC horizontal high speed v groove slotting machine from it is a professional and cost-effectiveness V grooving equipment.CNC Horizontal High Speed V Grooving Machine For Stainless Steel Plates

The CNC Horizontal High Speed V Grooving Machine For Stainless Steel Plates from Chinese manufacturer JM is not only to process stainless steel plate, but also can be used for cooper plates, aluminium plates, galvanized plates and son on.Horizontal Double Drive V Cutting Machine For Metal Plates

JM is a leading China Horizontal Double Drive V Cutting Machine For Metal Plates manufacturers. The professional metal plate manufacturer Jianmeng in China has a standardized production workshop. Currently, it has multiple intelligent horizontal double drive V cutting machine, these machines are cost-effective in stainless steel processing.Automatic Four Side CNC V Grooving Machine

JM is a professional leader China Automatic Four Side CNC V Grooving Machine manufacturer with high quality and reasonable price. A metal sheet v grooving machine can create V-shaped grooves in stainless steel sheets, aluminum sheets, composite aluminum sheets, copper sheets, and other metal plates. Four side v grooving machine realize the horizontal grooving of the plate. This allows the bent workpieces to have a very small edge radius, meeting the high precision and aesthetic demands of the high-end sheet metal decoration industry. JIANMENG provides various solutions, making metal fabrication easier!Pneumatic Metal Forming Machine

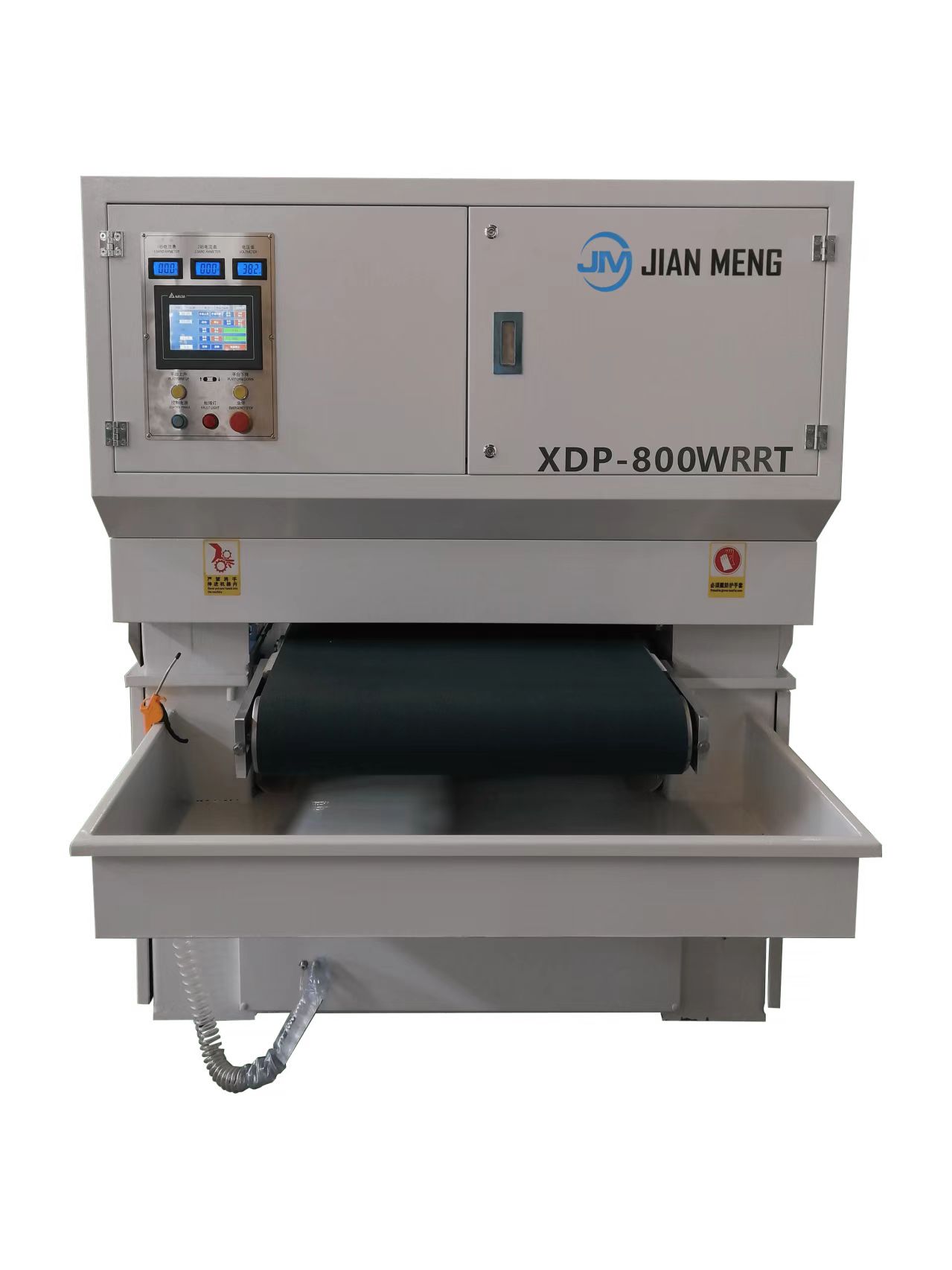

JIANMENG specializes in advanced Metal Shaping Machine, engineered for high-precision, chip-free processing of metal sheets with exceptionally low noise. These Metal shrinker machine support a wide range of metal forming applications, making them an ideal solution for both manufacturing new components and performing precise adjustments or repairs on existing parts. With rapid tool change capabilities and smooth transitions between functions, JIANMENG solutions are designed to maximize flexibility and efficiency. The PMF 400Metal Shaping Machine stands out with its reinforced structure and significantly increased forming pressure, enabling it to handle more demanding tasks. Its modular die system supports a variety of easily interchangeable tools—including shrinker and stretcher toolings—offering unmatched adaptability in metal forming operations. Built for long service life, high precision, and multifunctionality, JIANMENG delivers next-generation forming technology that sets a new standard for efficiency, control, and performance in modern metal fabrication.Wet Metal Deburring & Brushing & Polishing Machine

JM Wet Deburring Machine is a high-performance solution designed to efficiently remove burrs, slag, oxide layers, and sharp edges from metal sheets and plates. Utilizing wide abrasive belts in a wet processing environment, it delivers smooth, consistent surface finishes while eliminating harmful dust emissions. This makes it especially effective for post-processing after laser cutting, plasma cutting, or shearing. Equipped with a dual abrasive belt system, the machine ensures fast and uniform material removal across large surfaces. The wet grinding process not only cools the metal during operation—preventing heat-related distortion—but also extends the life of consumables. Its integrated filtration and water recirculation system supports clean, low-maintenance operation. Engineered for materials like stainless steel, aluminum, and copper, this sheet metal deburring machine is widely used in sectors including kitchen appliance manufacturing, electronics, and general metalworking. Compared to dry processing methods, it provides better surface quality, enhances workplace safety, and promotes environmentally responsible manufacturing.