- Horizontal V Grooving Machine

- Vertical V Grooving Machine

- Automatic Four Side V Grooving Machine

- V Grooving Machine Accessory

- Metal Forming Machine

- Deburring Machine

- Thin Sheet Deburring Machine

- Abrasive Belt Deburring Machine

- Carbon Steel Deburring Machine

- Deburring and Brushing Machine

- Manual Deburring Machine

- Wet Dust Collector

- Deburring Polishing & Brushing Machine

- Deburring & Chamfering Machine

- Wet Deburring & Brushing Machine

- Deburring, Edge rounding & Polishing Machine

- Carbon Steel Deburring & Brushing & Edge rounding Machine

- Dry Deburring, Brushing, and Polishing Machine

- Deburring and Brushing Machine with Slag Hammer Disc

- Shearing Machine

- Press Brake

CNC Guillotine Shearing Machine

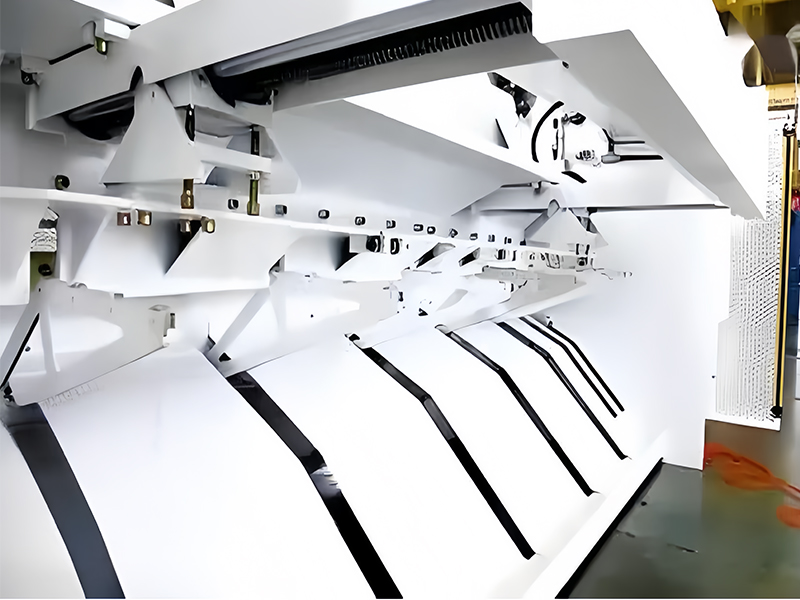

JM CNC Guillotine Shearing Machine is a commonly used shearing device in metal processing, primarily designed for cutting metal sheets of various thicknesses. It operates by applying a vertical downward motion of the upper blade against the lower blade, generating a shearing force to achieve precise cutting. It is mainly used for high-precision shearing of metal materials such as steel plates, stainless steel, and aluminum sheets. The shearing machine is widely applied in industries such as machinery manufacturing, automotive production, and electrical equipment manufacturing. The shearing method of the JM Guillotine Shearing Machine is similar to a "gate" moving up and down. Using hydraulic or mechanical transmission, the upper blade holder moves linearly downward along a fixed track (usually vertical or at an inclined angle) to shear metal sheets. With high shearing precision, it is especially suitable for cutting thick plates. JM shearing machine is designed for sheet metal processing, providing high-precision cutting solutions suitable for various metal sheets.

Model:QC11Y-6×2500

Send Inquiry

Guillotine Shearing Machine

Perfect Shearing: The QC11Y-6×2500 CNC Guillotine Shearing Machine achieves perfect cutting, efficiently and precisely processing various metal sheets to ensure smooth, burr-free edges with every cut. With advanced technology and high-precision control systems, it is widely used in industries such as machinery manufacturing, sheet metal processing, and automotive production for fine cutting of materials like steel plates, stainless steel, and aluminum sheets, meeting high-standard processing requirements.

|

Main configuration list |

Control System:Nanjing Estun (E21S) |

|

Internal Gear Pump:USA Sunny |

|

|

Main Motor:China Weite Motor |

|

|

Sealing Components:USA Parker |

|

|

Main Electrical Components:France Schneider |

|

|

Blade:China SJ |

|

|

Ball Screw:China Taiwan Hiwin |

E21S control system

The Estun E21S control system is a specialized CNC device designed for Guillotine Shearing Machine , suitable for a wide range of users. It significantly reduces the cost of CNC shearing machine while ensuring high work precision.

Back Gauge

Back Gauge System is a key component in sheet metal processing equipment, specifically in guillotine shears. It is responsible for accurately positioning the workpiece to ensure precision and consistency in cutting or bending operations. The structural design is robust, capable of withstanding the stresses of prolonged operation, and the linear guides enhance movement stability while reducing wear over time.

Spring Pressure Cylinder

The Spring Pressure Cylinder of a guillotine shear is a component used to assist in stabilizing and supporting the material, especially during the cutting process. The role of the Spring Pressure Cylinder is to ensure that the material is firmly pressed and held in place during cutting, preventing displacement or warping, thereby improving cutting accuracy and safety.

QC11Y-6×2500 Guillotine Shearing Machine

|

Maximum Shearable Plate Thickness ( Mild Steel) |

6.0mm |

|

Maximum Shearable Plate Thickness (Stainless Steel) |

3.0mm |

|

Plate Tensile Strength for Shearing |

450-650 N/mm2 |

|

Maximum Shearable Plate Width |

2500 mm |

|

Working Table Height |

800 mm |

|

Backgauge Stroke |

10-600 mm |

Clients’ Shearing Cases

A metal processing factory faced the challenge of processing various types of metal materials and aimed to improve production efficiency while reducing waste. To address this, we provided the factory with a JM guillotine shear, equipped with the E21S control system and hydraulic clamp, ensuring that each plate remained stable and immobile during the cutting process. After implementation, the cutting quality stabilized, and accuracy improved by 10%. Hourly production efficiency increased by 22%, and the factory saved material costs by reducing waste. The customer’s production cycle was shortened, allowing for timely order delivery and significantly enhancing their market competitiveness.