- Horizontal V Grooving Machine

- Vertical V Grooving Machine

- Automatic Four Side V Grooving Machine

- V Grooving Machine Accessory

- Metal Forming Machine

- Deburring Machine

- Thin Sheet Deburring Machine

- Abrasive Belt Deburring Machine

- Carbon Steel Deburring Machine

- Deburring and Brushing Machine

- Manual Deburring Machine

- Wet Dust Collector

- Deburring Polishing & Brushing Machine

- Deburring & Chamfering Machine

- Wet Deburring & Brushing Machine

- Deburring, Edge rounding & Polishing Machine

- Carbon Steel Deburring & Brushing & Edge rounding Machine

- Dry Deburring, Brushing, and Polishing Machine

- Deburring and Brushing Machine with Slag Hammer Disc

- Shearing Machine

- Press Brake

Manual metal sheet deburring machine

JM manual deburring machine is primarily used for removing burrs from the surface of metal workpieces. Due to its design and operation, the machine is suitable for fine surface deburring and polishing. The manual deburring machine effectively removes surface burrs, ensuring smooth and safe workpieces. It is widely used in sheet metal workpieces for medical devices, kitchenware, refrigerators, and other similar applications. JM manual deburring machine excels in surface deburring of metal workpieces. If your focus is on achieving smooth and high-quality surfaces, it provides an efficient and precise solution.

Model:XDP-1308D

Send Inquiry

Manual Deburring Machine

Perfect Deburring: The XDP-1308D manual deburring machine is commonly used in the metalworking industry, specially designed for removing burrs from the surface of workpieces. The machine is suitable for sheet metal parts such as medical devices, kitchenware, refrigerators, and more, providing smooth and high-quality surface finishing.

Manual Deburring Machine Structure

The manual deburring machine is constructed from high-strength metal, providing long-lasting stability and reliability. Its compact design saves space, making it well-suited for processing sheet metal workpieces in applications like medical devices, kitchenware, and refrigerators.

Abrasive Belt Motor

The manual deburring machine is typically equipped with a high-performance motor to provide stable and reliable power support, remove burrs, chamfer edges, and optimize the side quality of workpieces.

Worktable

The manual deburring machine features a stable and sturdy operating platform for placing workpieces.

After deburring:

After being processed by the manual deburring machine, the surface of the workpiece is smooth and free of burrs, ensuring safe handling and high precision. Any sharp or rough spots are removed, preventing interference during subsequent processing or assembly. The uniform surface provides a better foundation for operations such as welding, painting, or finishing.

XDP-1308D Machine Parameter

|

Worktable |

1300*800 mm |

|

Maximum Processing Thickness |

60 mm |

|

Grinding Motor |

1kW |

|

Voltage |

380V |

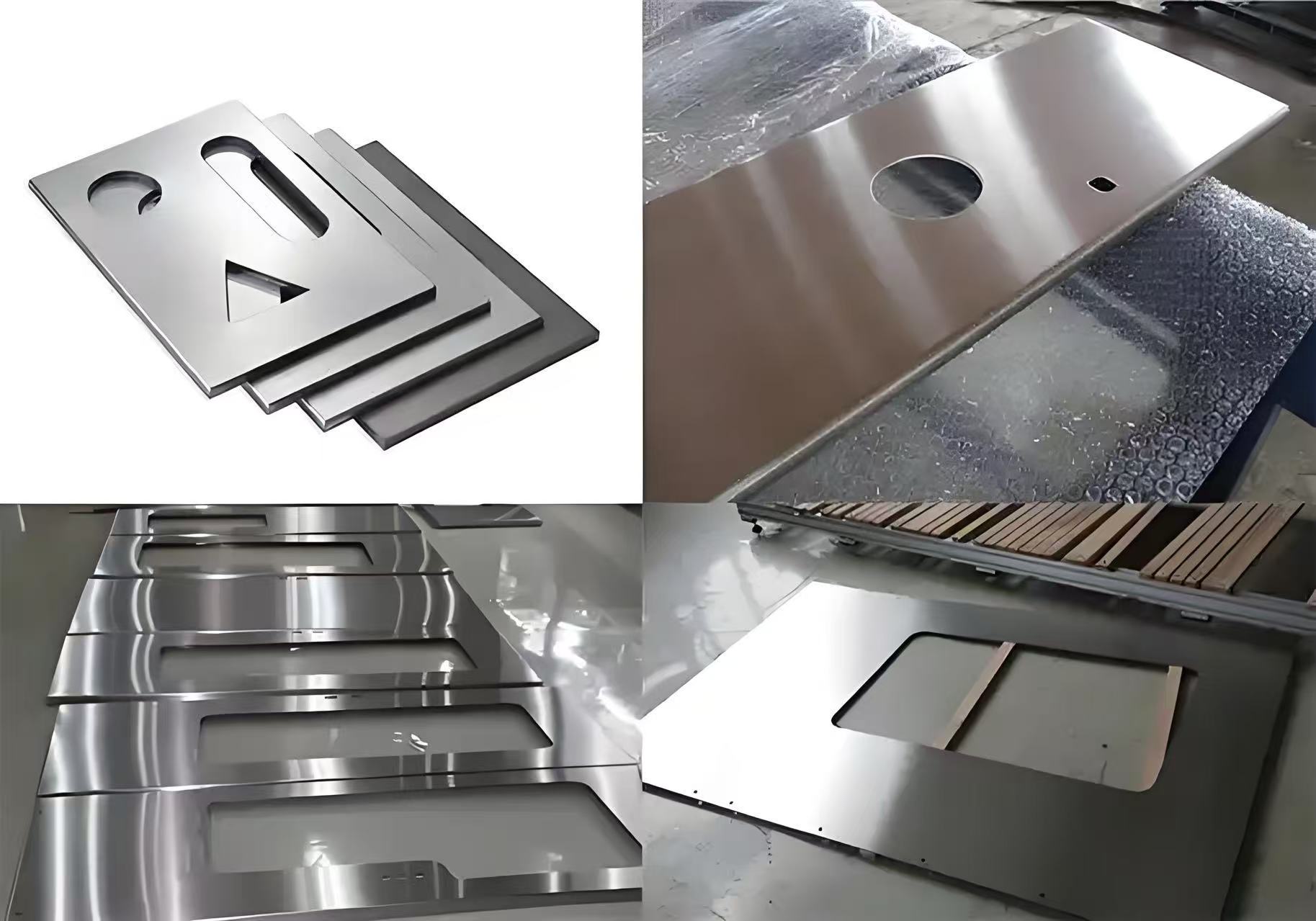

Clients’ Deburring Cases

A company specializing in kitchenware needed to remove burrs from the surface of metal components, so ordinary deburring machines were not suitable.

The company used a manual deburring machine for fine surface finishing, effectively removing burrs and ensuring product quality and safety. This improved the smoothness and uniformity of the workpiece surfaces, reduced the costs of subsequent processing and rework, and greatly increased overall efficiency.