- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

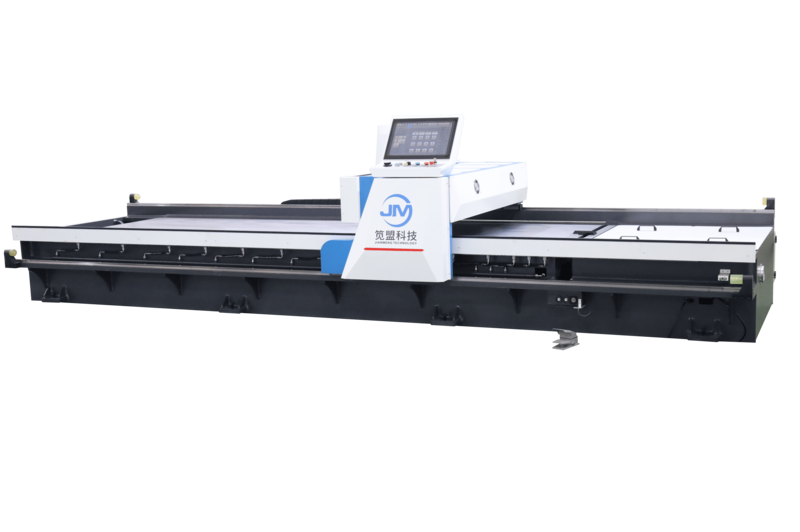

V-Grooving Machine: An Indispensable All-Rounder on the Production Line

2025-07-25

Speaking of V-grooving machines, many people may feel unfamiliar, but it is a "hidden champion" in industrial production. This machine is like a precise "scalpel" that specializes in making V-shaped grooves on materials. Don't be fooled by its simple shape, it is very sophisticated to use!

1. A great helper in the field of metal processing

In metal processing workshops, V-grooving machines are a powerful assistant for processing aluminum profiles and stainless steel. It can quickly open standard V-grooves, laying a good foundation for subsequent bending and welding. Especially when making door and window frames, the groove accuracy is directly related to the sealing of the final product.

2. Fine work of stone processing

Hard materials such as marble and granite can also be handled with V-grooving machines. It is necessary to open decorative grooves for stones or make transition grooves for splicing. Today's machines can also adjust the groove depth to meet different design requirements.

3. The secret weapon of woodworking

Don’t underestimate the softness of wood. Grooving is a big deal. The V-grooving machine can form a beautiful V-shaped seam on the edge of the board. This process is especially needed when making high-end furniture. Some masters also use it to make anti-skid grooves for wooden floors.

4. Flexible application of plastic processing

PVC and acrylic plastic materials can be processed with V-grooving machines to avoid cracking. Many of the splicing grooves of billboards and display racks are processed with this machine. Some models also have a cooling system to prevent plastic deformation.

5. Precision operation in the electronics industry

In circuit board processing, V-grooving machines are used to groove positioning holes. Although the grooves are small, the precision requirements are extremely high. If they are slightly off, the whole board will be scrapped. Today's CNC V-grooving machines can control the error within 0.01 mm.

6. Pioneer of new materials

With the increasing popularity of carbon fiber and composite materials, traditional grooving tools can no longer handle it. The new V-grooving machine uses diamond tools specifically for these high-tech materials. This equipment is widely used in the aerospace industry.

7. Practical tools for the maintenance industry

When repairing equipment, it is often necessary to groove. Portable V-grooving machines have become popular, especially when dealing with pipes and mechanical parts, which can quickly make standard grooves. Some masters say that this machine is more than ten times more efficient than hand tools.

8. Innovative means of artistic creation

Unexpectedly? Artists also use V-grooving machines. In the creation of wood carvings and metal sculptures, it is used to depict detailed lines. The special textures of some installation art works are processed by this machine.

9. All-round player in the construction industry

From steel structures to decorative lines, V-grooving machines can be seen everywhere on construction sites. It can not only groove, but some models can also do cutting and chamfering. The masters on the construction site all say that with it, at least three labors can be saved.

10. Intelligent Trends in Future Development

Now the latest V-grooving machines are equipped with intelligent control systems that can automatically identify material thickness and adjust the groove parameters. Some can also be connected to the Internet to transmit processing data to the cloud in real time. This machine is getting smarter and easier to operate.

In short, the V-grooving machine is like the "Swiss Army Knife" of the industrial world, seemingly simple but powerful. From traditional manufacturing to high-tech fields, from rough processing to precision operations, it can be found everywhere. Next time you see it in a factory, don't underestimate this "V" master!

As a professional manufacturer and supplier, we provide high-quality products. If you are interested in our products or have any questions, please feel free to contact us.