China V groove cutting machine Manufacturers, Suppliers, Factory

Our company insists all along the quality policy of "product good quality is base of enterprise survival; buyer fulfillment will be the staring point and ending of an company; persistent improvement is eternal pursuit of staff" and also the consistent purpose of "reputation very first, shopper first" for V groove cutting machine,V Grooving Machine,V cutting machine,V-Grooving & Laser Cutter,V Grooving & Laser Integrated Machine, We glance ahead to receiving your enquires quickly and hope to have the chance to operate together with you inside the future. Welcome to just take a seem at our organization.

V groove cutting machine, Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant expert knowledge, to develop advanced production equipment and production process , to create the first-call quality merchandise, reasonable price , high quality of service , quick delivery , to present you create new value .

Hot Products

Horizontal Double Drive V Cutting Machine For Stainless Steel Plate

The Chinese professional Horizontal Double Drive V Cutting Machine For Stainless Steel Plate manufacturer JM has over 10 years history in V grooving machine processing. Its horizontal double drive V cutting machine for stainless steel plate can make processing is stable and efficient.Vertical High Speed V Cutting Machine For Metal Plates

The V grooving machine manufacturer JM in China provide customer all over the world with the best vertical high speed V cutting machine for metal plates. This machine can cope with long time non-stop working state.Vertical High Speed V Groove Slotting Machine

The Vertical High Speed V Groove Slotting Machine manufacturer JM in China has a standard rack production workshop, with technological innovation as its core advantage. Its vertical high speed V grooving machine make use in processing mirror plates.Automatic Four Side CNC V Grooving Machine

JM is a professional leader China Automatic Four Side CNC V Grooving Machine manufacturer with high quality and reasonable price. A metal sheet v grooving machine can create V-shaped grooves in stainless steel sheets, aluminum sheets, composite aluminum sheets, copper sheets, and other metal plates. Four side v grooving machine realize the horizontal grooving of the plate. This allows the bent workpieces to have a very small edge radius, meeting the high precision and aesthetic demands of the high-end sheet metal decoration industry. JIANMENG provides various solutions, making metal fabrication easier!CNC Thin Sheet Deburring Machine

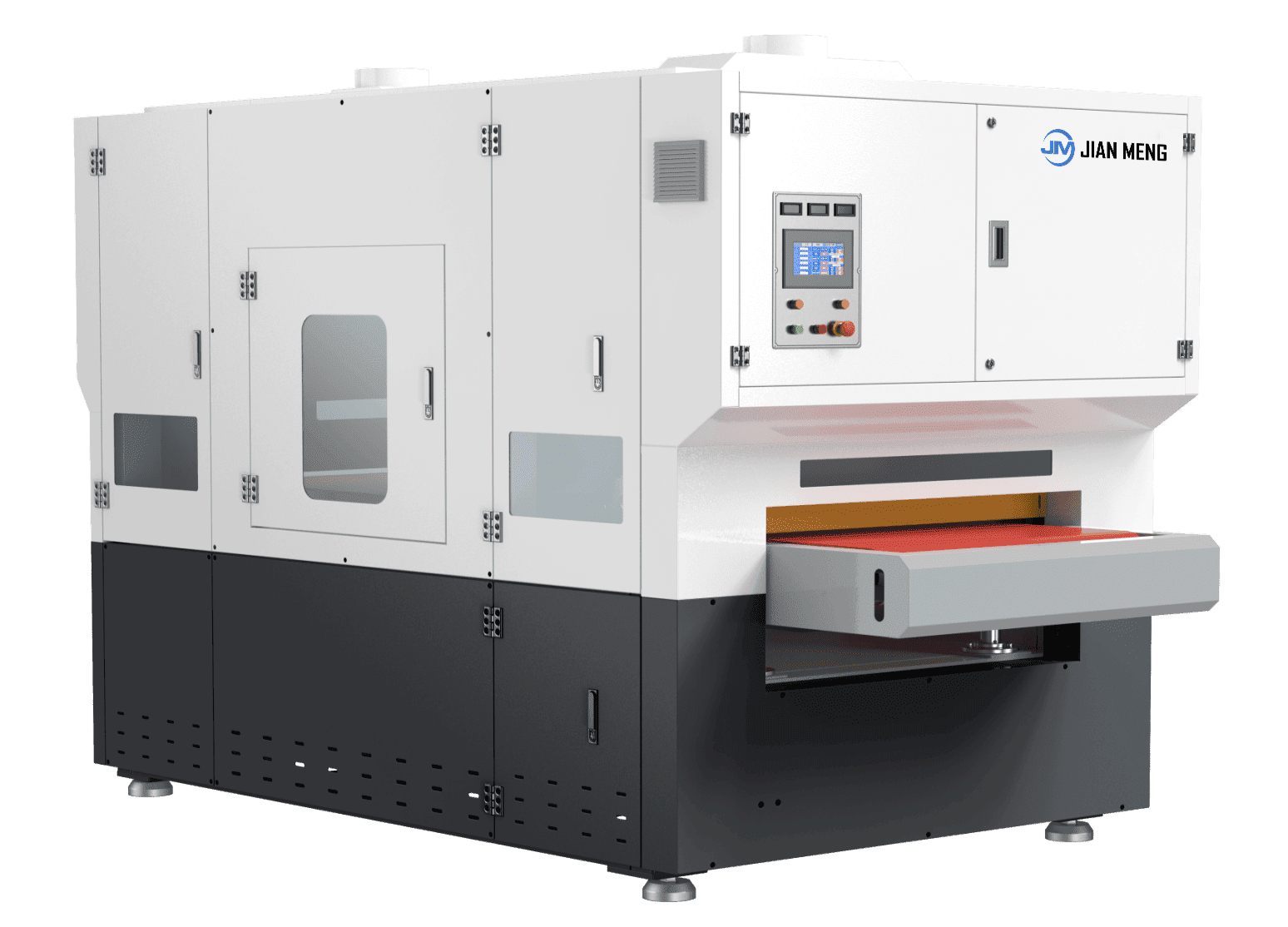

JM is a leading manufacturer specializing in CNC Thin Sheet Deburring Machine.The deburring machine is primarily used for deburring and chamfering the surfaces of various metal workpieces to improve surface quality. The JM deburring machine combines two functions: abrasive belt deburring and roller brush chamfering, allowing multiple surface processing steps to be completed in a single operation, thus enhancing production efficiency and product quality stability. It is suitable for materials such as stainless steel, aluminum alloy plates, steel plates, and copper plates. Different parameters can be adjusted, and appropriate abrasives can be selected based on processing requirements. JM Thin Sheet Deburring Machine, with its high efficiency, stability, and intelligent features, provides a one-stop surface treatment solution for metal processing enterprises. Whether it is improving workpiece quality or enhancing production efficiency, this machine meets all processing demands, making it an essential piece of equipment for modern manufacturing.CNC Carbon Steel Deburring &Brushing& Edge roundingBrushing Machine

The deburring and chamfering machine is specifically designed for surface treatment of carbon steel components. Automatic Deburring Machine features an innovative combination of three sets of wide abrasive belts and six universal rotary brushes for chamfering. This design ensures efficient and precise removal of surface burrs while achieving edge chamfering and surface brushing, significantly improving the surface quality and appearance of the workpiece. The Deburring & Brushing&edge rounding Machine meets the precision and quality requirements of carbon steel surface treatment across various industries, enhancing both production efficiency and product value. Parameters can be adjusted according to different processing needs, and suitable abrasives can be selected accordingly. The metal deburring machine is equipped with one 5.5kW wet dust collector. Dust removal method: The dust generated during operation is effectively extracted through a dust collection port, eliminating most of the dust, preventing potential dust explosion hazards, and keeping the internal structure clean.