- Horizontal V Grooving Machine

- Vertical V Grooving Machine

- Automatic Four Side V Grooving Machine

- V Grooving Machine Accessory

- Metal Forming Machine

- Deburring Machine

- Thin Sheet Deburring Machine

- Abrasive Belt Deburring Machine

- Carbon Steel Deburring Machine

- Deburring and Brushing Machine

- Manual Deburring Machine

- Wet Dust Collector

- Deburring Polishing & Brushing Machine

- Deburring & Chamfering Machine

- Wet Deburring & Brushing Machine

- Deburring, Edge rounding & Polishing Machine

- Carbon Steel Deburring & Brushing & Edge rounding Machine

- Dry Deburring, Brushing, and Polishing Machine

- Deburring and Brushing Machine with Slag Hammer Disc

- Shearing Machine

- Press Brake

Vertical V-Grooving and Laser Cutting Integrated Machine

This Vertical V-Grooving and Laser Cutting Integrated Machine automates the entire process of transforming flat sheets into finished products. This Vertical V-Grooving and Laser Cutting Integrated Machine combines high-precision laser cutting for smooth, burr-free edges and intelligent V-grooving for creating sharp, clean folds. Simply send your digital design, and the system automatically handles all the steps, boosting efficiency over 3 times and ensuring top quality—ideal for architectural decoration and artistic installations.

Model:100T/3200

Send Inquiry

Product Overview

This Vertical V-Grooving and Laser Cutting Integrated Machine automates the entire process of transforming flat sheets into finished products. This Vertical V-Grooving and Laser Cutting Integrated Machine combines high-precision laser cutting for smooth, burr-free edges and intelligent V-grooving for creating sharp, clean folds. Simply send your digital design, and the system automatically handles all the steps, boosting efficiency over 3 times and ensuring top quality—ideal for architectural decoration and artistic installations.

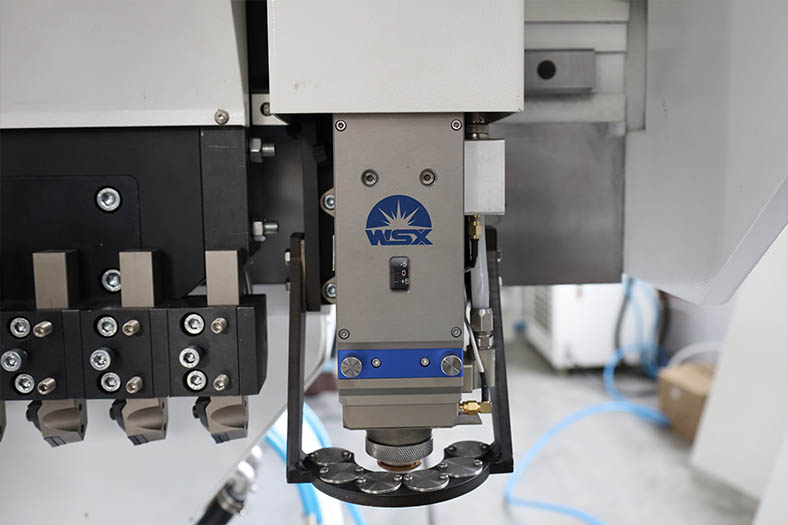

Cutting Head

The laser cutting head is the "executive end-effector" of a laser cutting machine. It precisely focuses the high-energy beam generated by the laser source onto the workpiece surface to melt or vaporize the material for cutting. Its core components—including the focusing lens, protective lens, nozzle, and follow-up system—work together to control the focal position, provide assist gas, and maintain a stable cutting distance. Its performance directly determines the cutting accuracy, speed, and edge quality.

Laser Source

It generates a powerful, concentrated beam of light called a laser. This beam is focused into an extremely fine, high-energy point that acts like an ultra-sharp, super-hot "light knife.This "light knife" instantly melts or vaporizes materials upon contact, allowing the machine to cut with incredible precision, smooth edges, and without any physical force or tool wear.

Follow-up controller

The follow-up controller acts as the core "sensory nerve" for the laser cutting head. It utilizes high-precision sensors to continuously monitor the distance between the nozzle and the material surface, then instantly drives a servo motor to adjust the head height. This ensures a constant focus position and standoff distance, guaranteeing cutting quality and effectively preventing collisions.

Chiller

The chiller is the machine's air conditioner.It circulates cooled water to the laser source and other components to keep them from overheating. This prevents damage and ensures stable, precise operation during long working hours.

Product Specifications

Category

Item

Parameter

Processing Range

Maximum Plate Width

1500 mm

Maximum Plate Length

4000 mm

Maximum Plate Thickness

6 mm

Minimum Plate Thickness

0.4mm

Minimum V-groove distance from edge

8.0mm

Minimum laser cutting distance from edge

25mm

Maximum Axis Speed

X-axis Speed

100m/min

Y-axis Speed

80m/min

Z1/Z2/A-axis Speed

10m/min

Power Consumption

X-axis Servo Motor Power

4.4KW

Y-axis Servo Motor Power

4.4KW

Z1/Z2/A-axis Servo Motor Power

0.75KW

4.Configuration List

Our component suppliers are all internationally renowned brands, ensuring reliable quality and worry-free after-sales service.

Structural Design

This Vertical V-Grooving and Laser Cutting Integrated Machine features a vertical, integrated welded bed and precision rack-and-pinion drive, establishing a foundation of high rigidity and stability. Its unique universal ball worktable effectively protects sheet surfaces and ensures smooth feeding. Combined with core components treated with vibration aging, it collectively guarantees exceptional machining accuracy and an extended service life, even under long-term, high-intensity operation.

Options

Air Compressor:The air compressor provides a stable air supply for the equipment, ensuring the proper operation of pneumatic components and improving the overall stability and efficiency of the system.

Voltage Stabilizer:It provides stable voltage to the equipment, preventing malfunctions caused by voltage fluctuations, thus improving operational reliability and extending service life.

Dust collector:The dust collector, or dust and smoke purifier, is an essential component designed to capture and filter harmful particulate matter and fumes generated during laser cutting and grooving processes. By extracting pollutants directly at the source and purifying the air through a multi-stage filtration system—including features such as a spray tower—it effectively maintains workshop air quality, ensures compliance with environmental standards, and safeguards operator health by reducing exposure to hazardous airborne contaminants.

Light Curtain Safety Device:A reliable light curtain that protects personnel’s safety, significantly reducing the risk of injuries.

Application

Home Appliance Industry

In furniture manufacturing, this Vertical V-Grooving and Laser Cutting Integrated Machine can process metal furniture frames, decorative inserts, and custom furniture components. It achieves precise tube cutting and connection groove processing, combined with 3D bending technology, to create modern metal furniture while ensuring assembly accuracy and structural strength.

Construction Industry

In the construction industry, this Vertical V-Grooving and Laser Cutting Integrated Machine excels in producing building facade panels, metal curtain wall units, and artistic components. Through precise cutting and grooving, it achieves complex geometric shapes for building facades, ensures component connection accuracy, while maintaining material surface integrity, meeting the dual requirements of precision and aesthetics in modern architecture.

Decorative Industry

In the decoration industry, this Vertical V-Grooving and Laser Cutting Integrated Machine can precisely process metal decorative materials such as stainless steel and brass to create complex artistic patterns, hollow screens, and relief effects. Its laser cutting achieves mirror-finish processing, while V-grooving creates three-dimensional edges, meeting the aesthetic demands of high-end interior and exterior decoration.

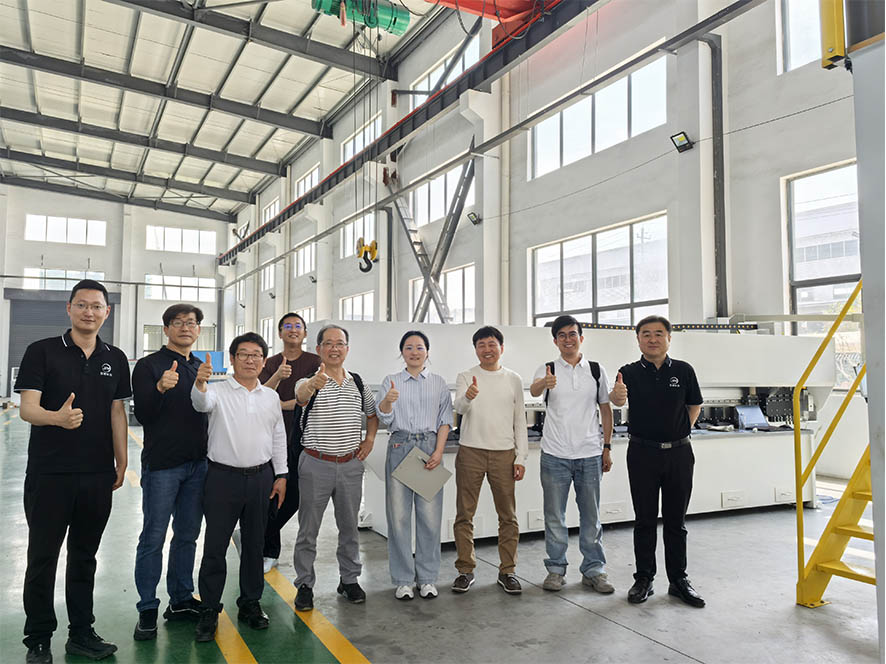

Customer Case

In this project, we supplied Vertical V-Grooving and Laser Cutting Integrated Machine to a well-known manufacturer in South Korea.

The clients provided positive feedback regarding the machine’s precision, stability, and overall operating performance.

Through continuous communication and technical support, we have built a stable and reliable partnership with these customers.