China Steel Plate Numeric Control V Groove Machine Manufacturers, Suppliers, Factory

Our personnel are generally in the spirit of "continuous improvement and excellence", and together with the outstanding top quality merchandise, favorable price tag and fantastic after-sales solutions, we try to gain every single customer's rely on for Steel Plate Numeric Control V Groove Machine,Automatic V Groove Notcher,Automatic V Groove Welding System,Precision V Groove Shearing Machine,Precision V Groove Welding Equipment, Warmly welcome to cooperate and develop with us! we will continue to provide product with high quality and competitive price.

Steel Plate Numeric Control V Groove Machine, Now, with the development of internet, and the trend of internationalization, we've got decided to extend business to overseas market. With the propose of bringing more profits to oversea customers by providing directly abroad. So we have changed our mind, from home to abroad, hope to give our customers more profit, and looking forward to more chance to make business.

Hot Products

CNC Horizontal Double Drive V Groove Cutting Machine

The Chinese V grooving machine manufacturer JM has been focus on CNC Horizontal Double Drive V Groove Cutting Machine for many years. Its CNC horizontal double drive V groove cutting machine is effective and competitive in market.The CNC horizontal double drive V groove machine from Chinese manufacturer Jianmeng is equipped with intelligent system, easy to master and operate.CNC Vertical High Speed V Slotting Machine For Metal Plates

The CNC vertical high speed V slotting machine for metal plates from professional Chinese V slotting machine manufacturer JM has a long service life, this machine with easy CNC operating system, and can automatically processing by inputting parameters.TAEGUTEC Knife

JM is the professional V grooving machine manufacturer in China, it offers equipment and accessory with good quality. The TAEGUTEC knife from JIANMENG is negative Square inserts for medium rough applications of steel, cast iron and stainless steel.Vertical V Grooving Machine with Two Head

High quality Vertical V Grooving Machine with Two Head is offered by China manufacturer JM. Grooving machine is highly effective in precision work and corner bending to maintain edges. By using V grooving machine which is stable to bend metal sheets, they can be folded into tight, seamless workpieces.Vertical CNC V Groove Machine for Metal Sheet

JM is a leading China vertical cnc v groove machine for metal sheet manufacturer. A metal sheet v grooving machine can create V-shaped grooves in stainless steel sheets, aluminum sheets, composite aluminum sheets, copper sheets, and other metal plates. Vertical v cut machine allows the bent workpieces to have a very small edge radius, meeting the high precision and aesthetic demands of the high-end sheet metal decoration industry. JIANMENG provides various solutions, making metal fabrication easier!Wet Metal Deburring & Brushing & Polishing Machine

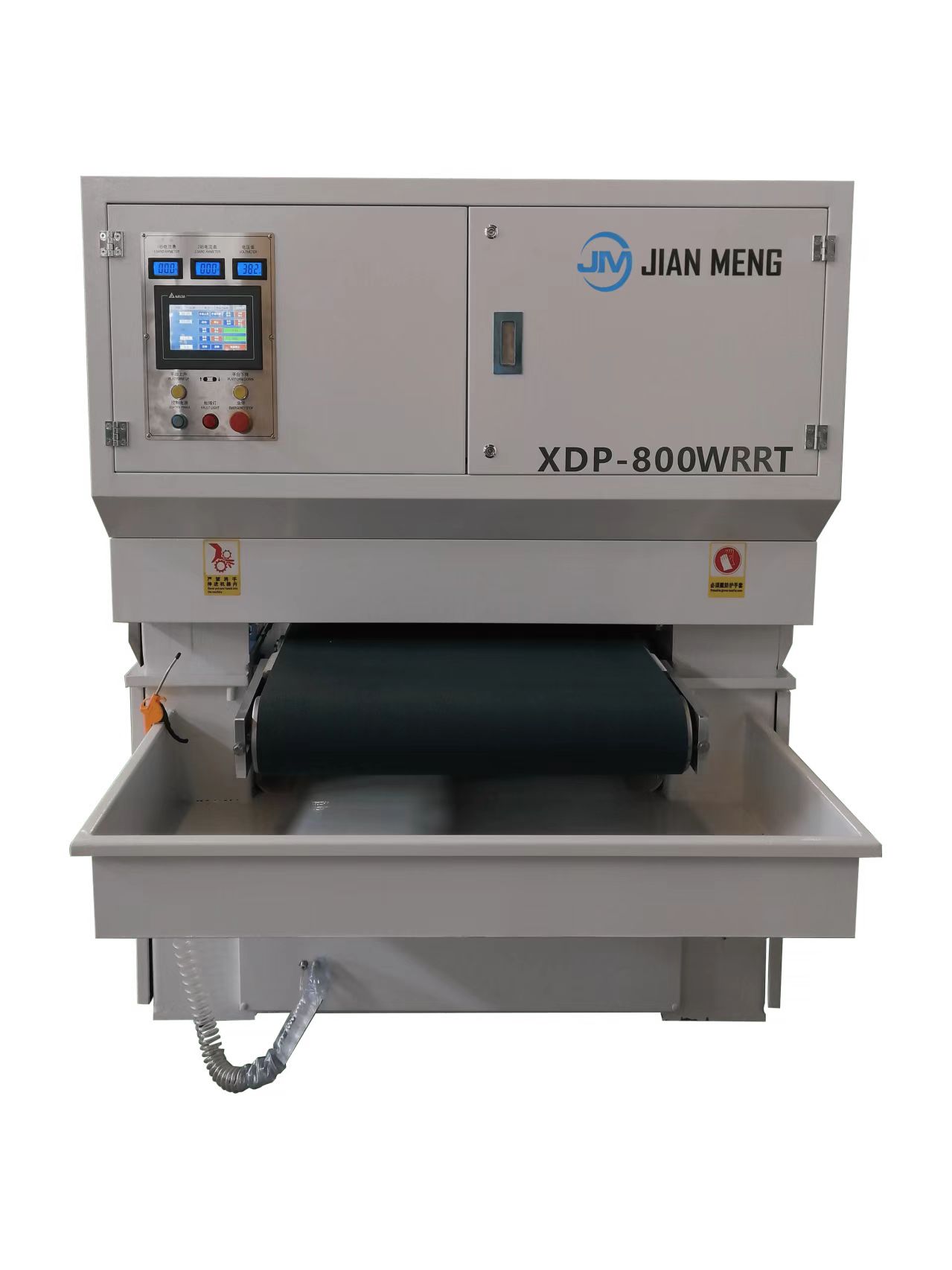

JM Wet Deburring Machine is a high-performance solution designed to efficiently remove burrs, slag, oxide layers, and sharp edges from metal sheets and plates. Utilizing wide abrasive belts in a wet processing environment, it delivers smooth, consistent surface finishes while eliminating harmful dust emissions. This makes it especially effective for post-processing after laser cutting, plasma cutting, or shearing. Equipped with a dual abrasive belt system, the machine ensures fast and uniform material removal across large surfaces. The wet grinding process not only cools the metal during operation—preventing heat-related distortion—but also extends the life of consumables. Its integrated filtration and water recirculation system supports clean, low-maintenance operation. Engineered for materials like stainless steel, aluminum, and copper, this sheet metal deburring machine is widely used in sectors including kitchen appliance manufacturing, electronics, and general metalworking. Compared to dry processing methods, it provides better surface quality, enhances workplace safety, and promotes environmentally responsible manufacturing.