- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Vertical Laser & V Cutting Machine

2025-08-02

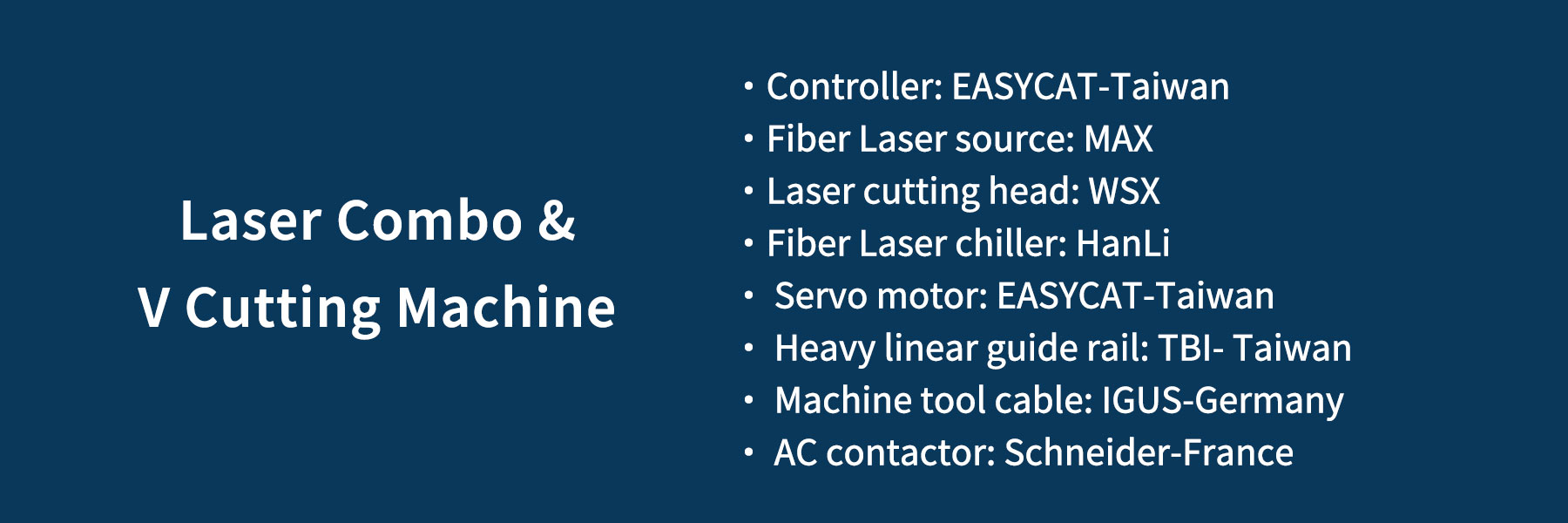

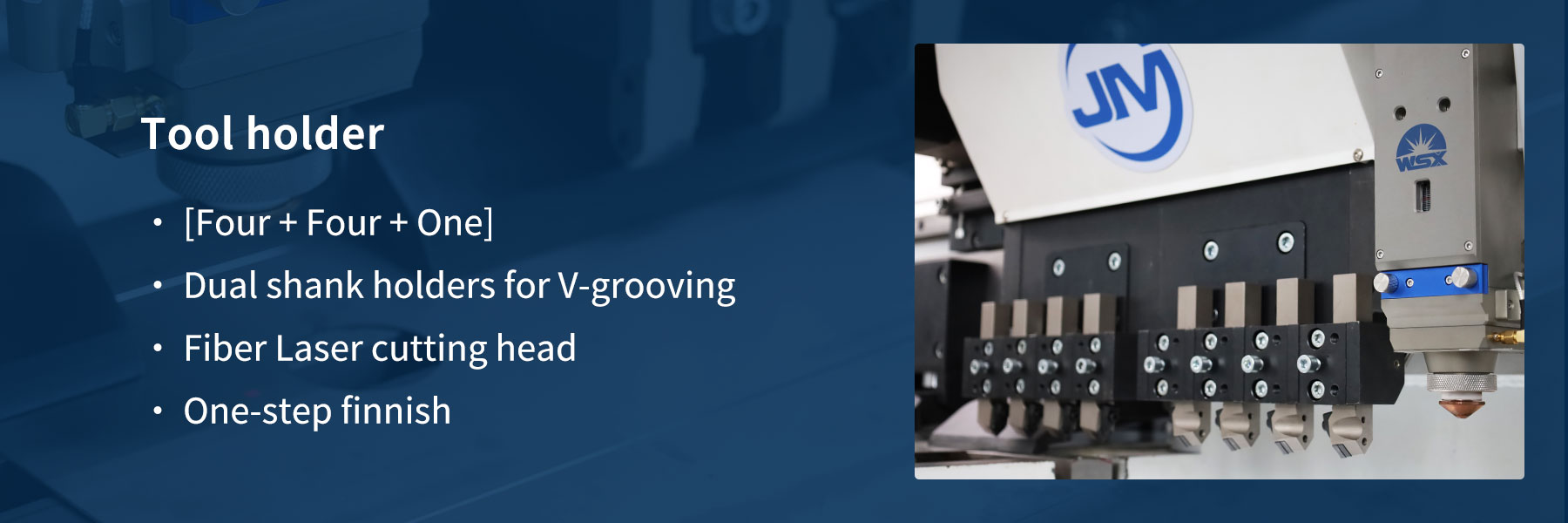

Our Vertical Laser Cutting Combo V Grooving Machine. It’s a 3-in-1 system: laser cutting, shearing, and v grooving — all integrated into one compact machine. Compared to using three separate machines, this combo design saves up to 50% of your workshop space — no need to shuffle materials from one machine to another. One setup, multiple functions — this machine cuts, shears, and grooves with one loading. It simplifies your workflow and improves production efficiency dramatically.

| Parameter |

|

|

Maximum plate thickness (stainless steel) |

6.0mm |

|

Minimum plate thickness |

0.4mm |

|

Minimum V-groove distance from edge |

8.0mm |

|

Minimum laser cutting distance from edge |

25mm |

|

Table flatness |

0.03mm |

| Dimension | 5700*2900*2100mm |

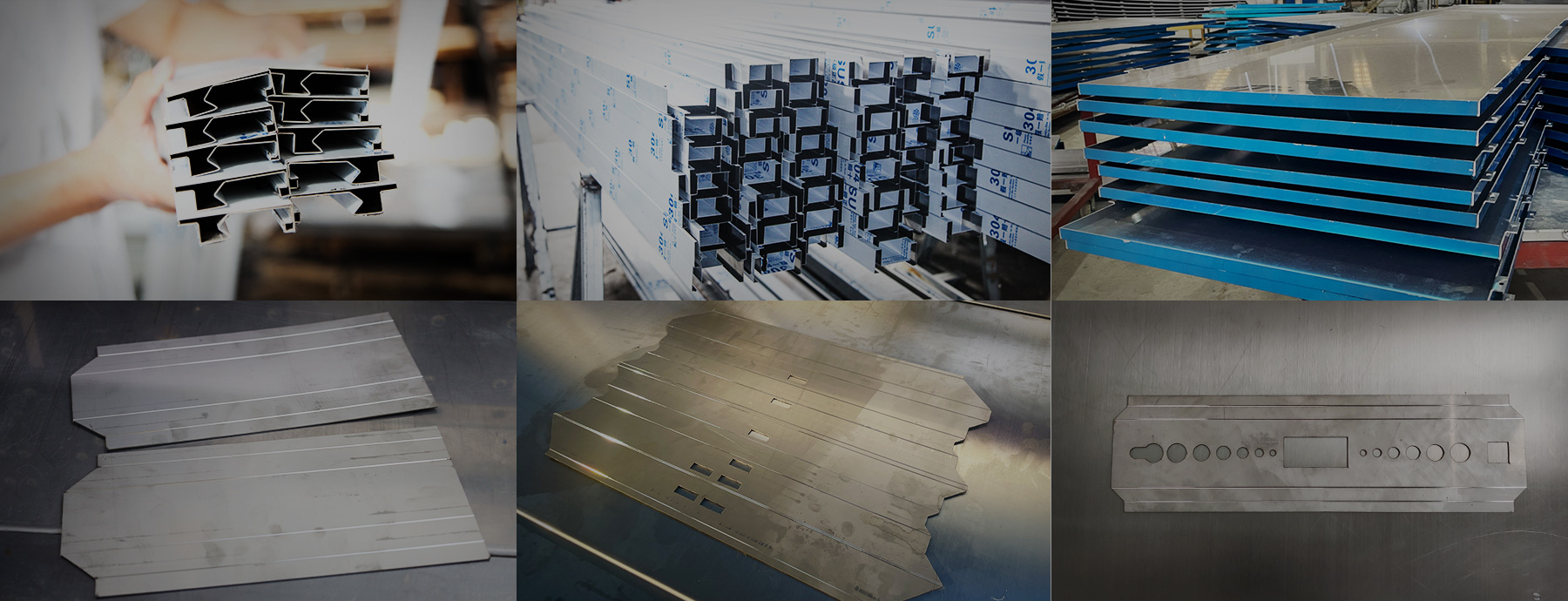

Clients’ Grooving Cases

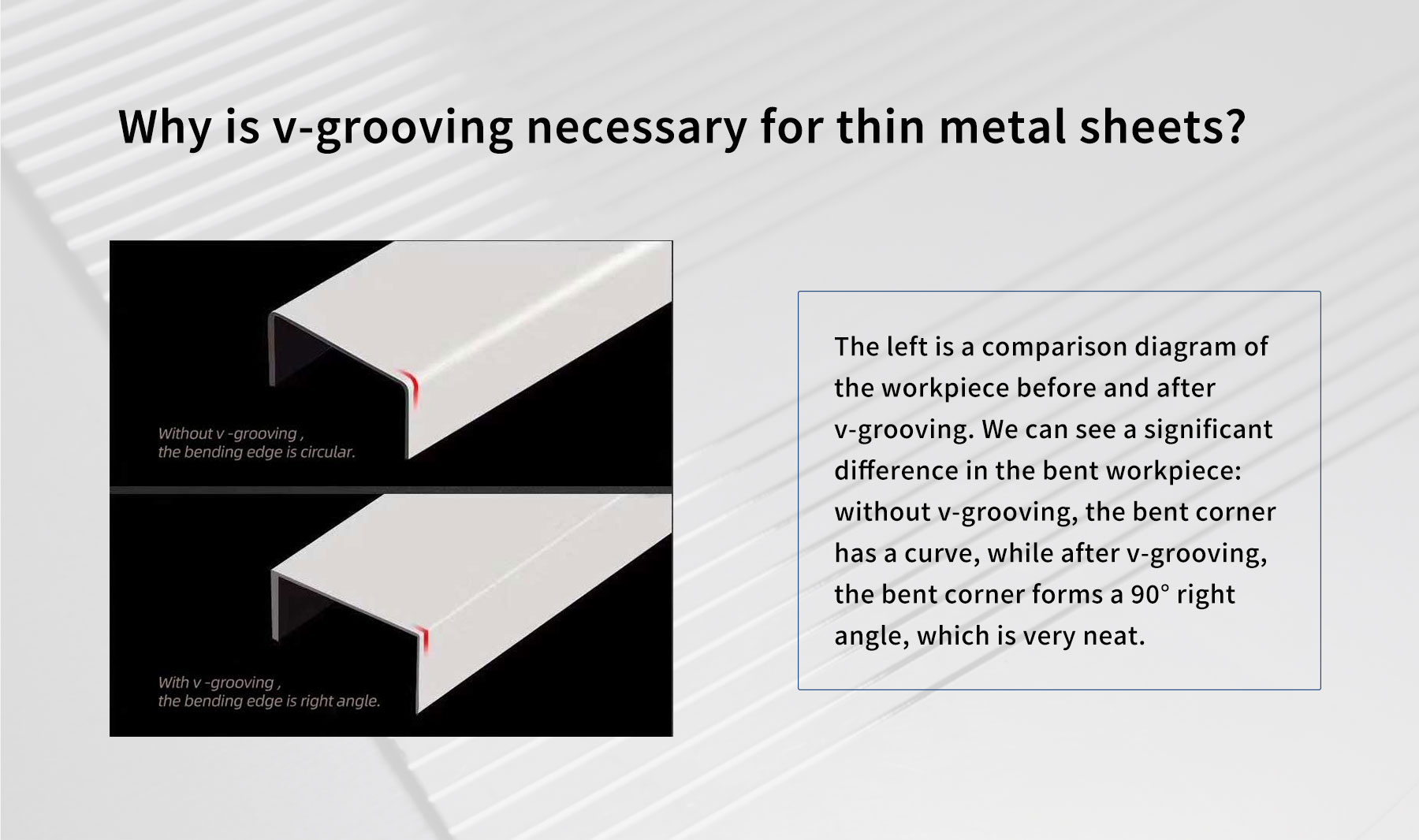

After customers adopt our CNC v grooving laser cutting combo machine, they can notice significant improvements in the quality and precision of the bending and laser cutting workpieces. The consistent and uniform grooves created by the machine allow for a smoother and more controlled bending process. This leads to workpieces with better-defined shapes, reduced material distortion, and enhanced overall structural integrity.

Our customers can achieve superior bending outcomes regardless of the specific material or specifications of the workpieces. It means our CNC v cut machine significantly meet and exceed the expectations of our customers.

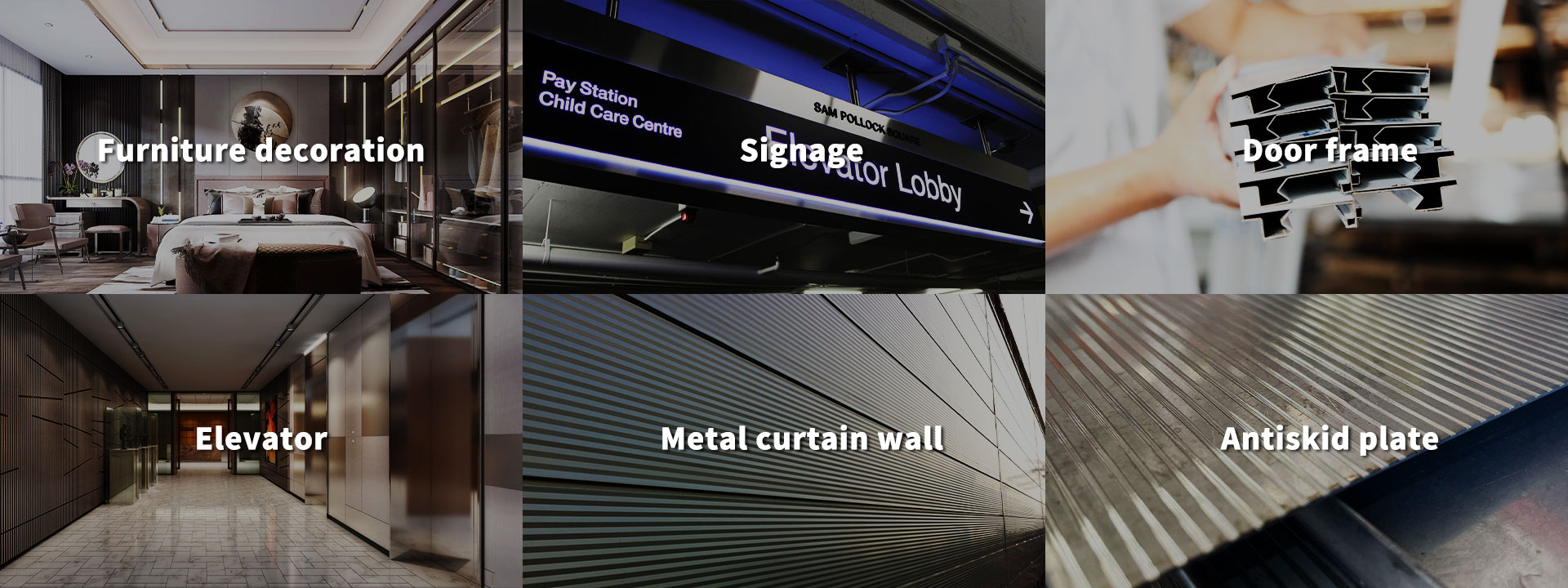

Application

Our CNC Automatic Four Side CNC V Grooving Machine is widely used in various metal processing industries such as architectural decoration, sanitary ware, kitchenware, door manufacturing, elevator equipment, advertising signage, equipment enclosures, and aluminum curtain walls. Many customers also use this v grooving machine in the automotive manufacturing, machinery, electrical equipment, precision parts, hardware products, and aluminum and copper products industries.