- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Shearing Machine High-Speed Cutting Manufacturers, Suppliers, Factory

We hold strengthening and perfecting our items and repair. At the same time, we get the job done actively to do research and progress for Shearing Machine High-Speed Cutting,Shearing Machine for Carbon Steel,Sheet Metal Cutting,Shearing Machine for Aluminum Sheet,Shearing Machine for Construction Industry, We welcome new and aged buyers from all walks of lifetime to make contact with us for potential small business associations and mutual success!

Shearing Machine High-Speed Cutting, Welcome to visit our company, factory and our showroom where displays various hair merchandise that will meet your expectation. Meanwhile, it is convenient to visit our website, and our sales staff will try their best to deliver you the best service. Make sure you contact us if you require more information. Our aim is to help customers realize their goals. We're making great efforts to achieve this win-win situation.

Hot Products

V-Shaped Grooving Machine

The horizontal high speed v-shaped grooving machine is a professional V grooving equipment produced by JM, a manufacturer in China with the most types of V grooving machines. The horizontal high speed v-shaped grooving machines have high economic benefits and cost-effectiveness at medium to low utilization rates.Horizontal Double Drive V-Shaped Grooving Machine

The horizontal double drive V-shaped grooving machine from the professional v grooving machine manufacturer JM in China, this machine supports fixed-point grooving, processing of dissimilar work.Vertical High Speed V Cutting Machine

The vertical high speed V cutting machine is one of the best-selling grooving machines from Chinese professional V grooving machine manufacturer JM. The vertical high speed V cutting machine is stable and reliable during processing.CNC Vertical Back And Forth Grooving Machine

The V grooving machine manufacturer JM in China offers the leading CNC Vertical Back And Forth Grooving Machine. The CNC vertical back and forth V grooving machines completely solves the problem of deformation of working table, ensures the flatness of working table(+0.3mm),and solves the problem of depth accuracy affecting the quality of slotting.CNC Carbon Steel Deburring &Brushing& Edge roundingBrushing Machine

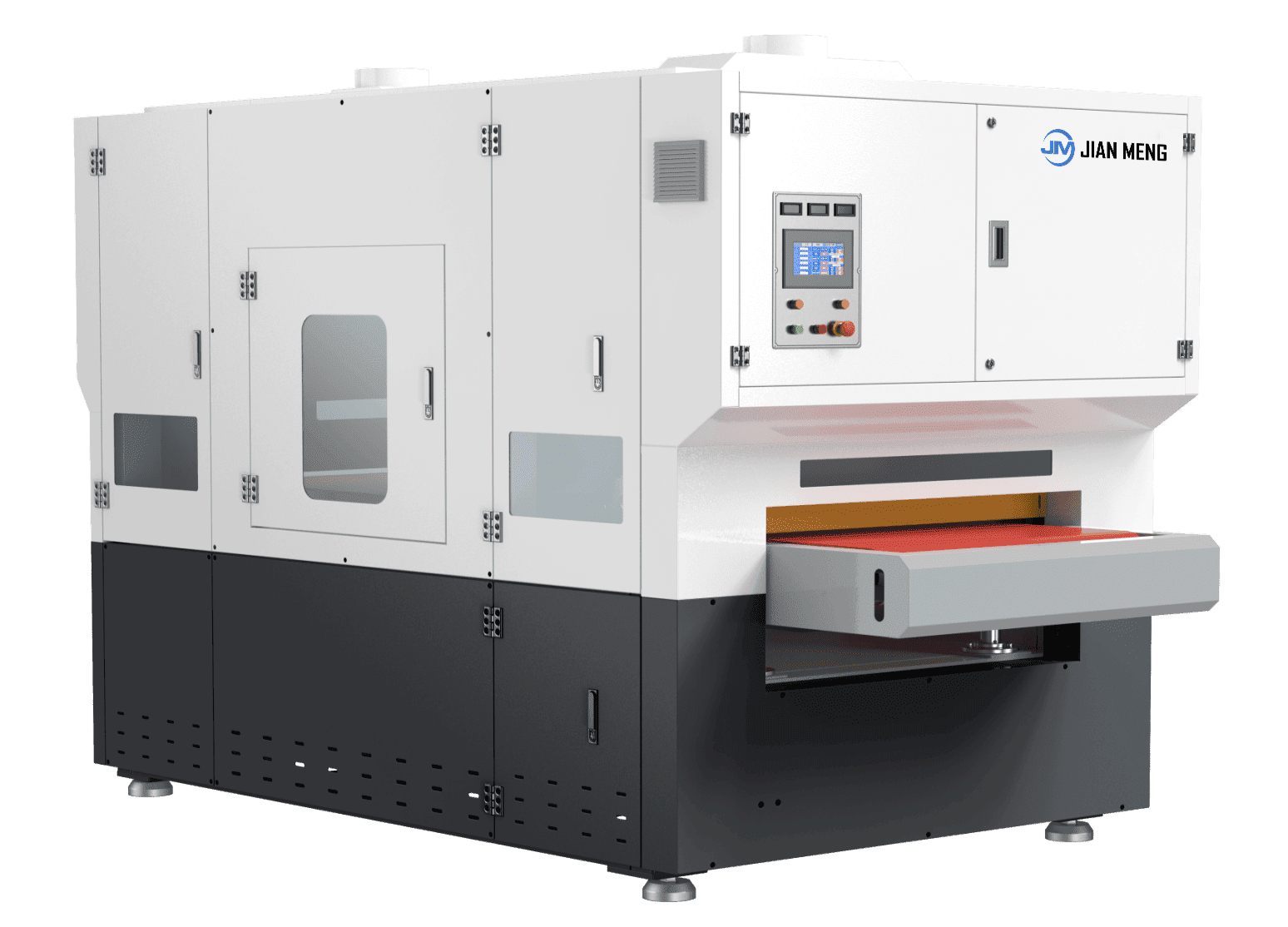

The deburring and chamfering machine is specifically designed for surface treatment of carbon steel components. Automatic Deburring Machine features an innovative combination of three sets of wide abrasive belts and six universal rotary brushes for chamfering. This design ensures efficient and precise removal of surface burrs while achieving edge chamfering and surface brushing, significantly improving the surface quality and appearance of the workpiece. The Deburring & Brushing&edge rounding Machine meets the precision and quality requirements of carbon steel surface treatment across various industries, enhancing both production efficiency and product value. Parameters can be adjusted according to different processing needs, and suitable abrasives can be selected accordingly. The metal deburring machine is equipped with one 5.5kW wet dust collector. Dust removal method: The dust generated during operation is effectively extracted through a dust collection port, eliminating most of the dust, preventing potential dust explosion hazards, and keeping the internal structure clean.CNC Deburring, Brushing & Polishing Machine for metal sheet

JM is a premier manufacturer committed to delivering cutting-edge solutions in metal surface finishing. Our advanced deburring, polishing, and brushing systems combine efficiency, precision, and intelligence—integrating deburring, polishing, oxide removal, chamfering, and surface brushing into a single, seamless process. Designed for the demanding needs of sheet metal fabrication, automotive components, and precision instrument industries, JM’s Industrial Deburring Machines ensure perfectly smooth, safe edges on stainless steel, carbon steel, aluminum, and copper. With outstanding performance in efficiency, stability, and smart control, our automatic systems help manufacturers enhance product quality, maintain consistency, and accelerate production—offering a dependable, all-in-one solution for superior surface treatment. For enterprises pursuing excellence in metal processing, JM’s technology stands as the trusted choice for achieving flawless results.