- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Metal Plate V Groove Cutter Manufacturers, Suppliers, Factory

We are commitment to offer the competitive price ,outstanding products quality, as well as fast delivery for Metal Plate V Groove Cutter,Automatic V Groove Notcher,Automatic V Groove Welding System,Precision V Groove Shearing Machine,Precision V Groove Welding Equipment, On account of superior top quality and aggressive selling price , we'll be the market leader, be sure to don’t wait to get in touch with us by phone or email, should you be intrigued in almost any of our products.

Metal Plate V Groove Cutter, Ensuring high product quality by choosing the best suppliers, we have also implemented comprehensive quality control processes throughout our sourcing procedures. Meanwhile, our access to a large range of factories, coupled with our excellent management, also ensures that we can quickly fill your requirements at the best prices, regardless the order size.

Hot Products

Horizontal High Speed V Cutting Machine

The horizontal high speed V cutting machine is a professional V cutting equipment produced by JM, the Chinese manufacturer with the most types of V grooving machines. The horizontal high speed cutting machines have high cost-effectiveness at medium to low utilization rates.Horizontal Double Drive V Slotting Machine For Metal Plates

The Chinese manufacturer JM has been at forefront of Horizontal Double Drive V Slotting Machine For Metal Plates manufacturing, with technological innovation as its core advantage. The horizontal double dive V slotting machine for metal plates is efficient.Horizontal Double Drive V Slotting Machine For Stainless Steel Plate

The professional V grooving machine manufacturer JM in China not only has excellent horizontal double drive V slotting machine for stainless steel plate, but also provide considerate after-sales service. The groove processed by horizontal double drive V slotting machine for stainless steel plate is as smooth as a mirror.Automatic Four Side V Cutting Machine

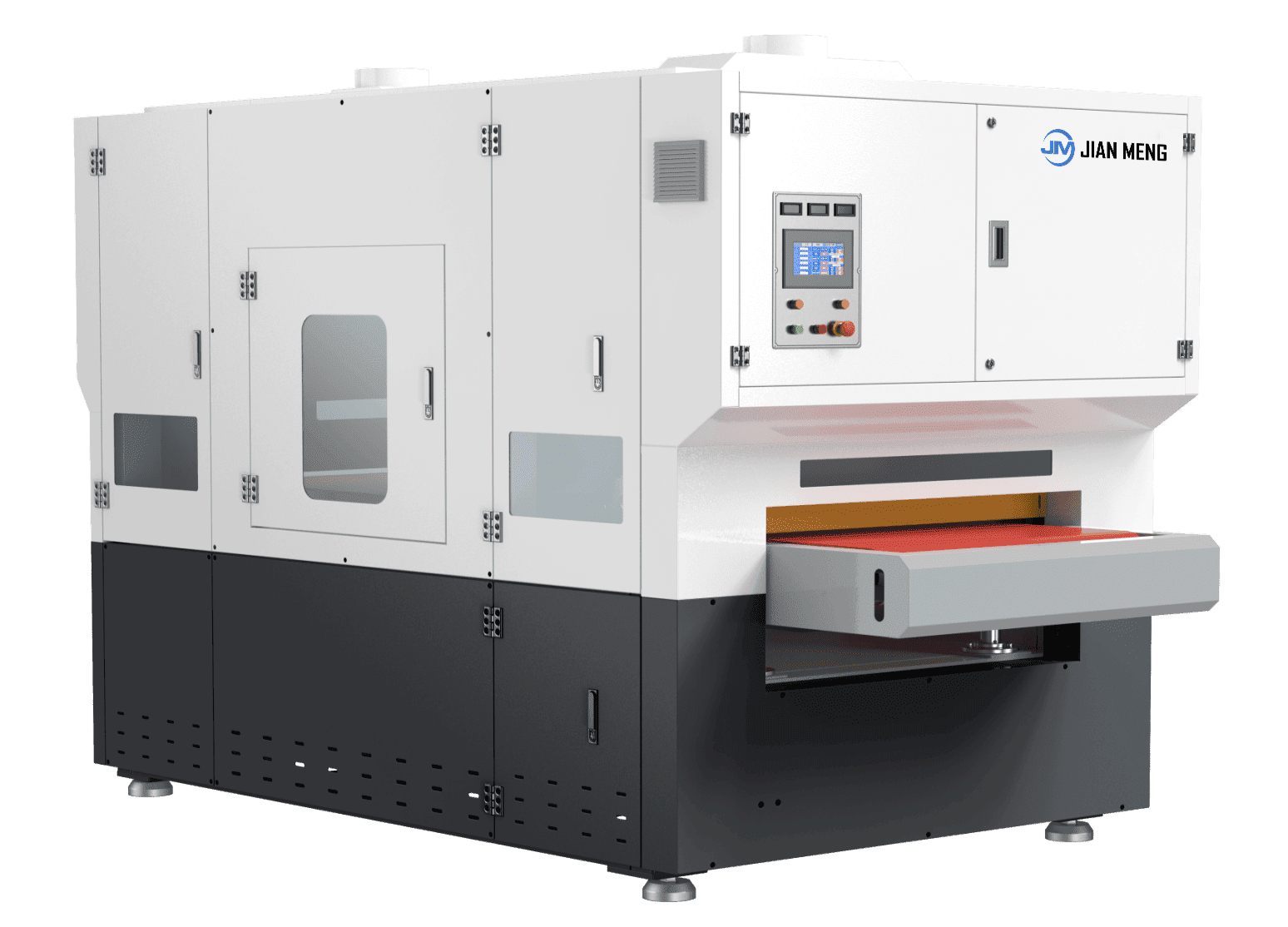

As the professional automatic four side V cutting machine manufacturer in China, JM strictly controlled the product quality and witnessed the rapid and solid development of the brand benefiting from the high quality products. The automatic four side V cutting machine is more useful for machining on four sides.Automatic Thin Sheet Deburring Machine

JM is a leading manufacturer dedicated to advanced thin sheet deburring solutions. Our deburring machine is designed to efficiently remove burrs and perform chamfering on a wide range of metal workpieces, ensuring superior surface quality. By integrating abrasive belt deburring with roller brush chamfering, the machine enables multiple surface finishing processes in a single pass, significantly boosting both production efficiency and product consistency. Automatic Deburring Machine is compatible with materials such as stainless steel, aluminum alloys, steel plates, and copper plates. Operators can easily adjust processing parameters and select the most suitable abrasives according to specific requirements. With its high efficiency, operational stability, and intelligent control features, the JM Thin Sheet Deburring Machine offers metalworking enterprises a truly one-stop surface treatment solution. From enhancing product quality to streamlining production, it is an indispensable asset for modern manufacturing.CNC Carbon Steel Deburring &Brushing& Edge roundingBrushing Machine

The deburring and chamfering machine is specifically designed for surface treatment of carbon steel components. Automatic Deburring Machine features an innovative combination of three sets of wide abrasive belts and six universal rotary brushes for chamfering. This design ensures efficient and precise removal of surface burrs while achieving edge chamfering and surface brushing, significantly improving the surface quality and appearance of the workpiece. The Deburring & Brushing&edge rounding Machine meets the precision and quality requirements of carbon steel surface treatment across various industries, enhancing both production efficiency and product value. Parameters can be adjusted according to different processing needs, and suitable abrasives can be selected accordingly. The metal deburring machine is equipped with one 5.5kW wet dust collector. Dust removal method: The dust generated during operation is effectively extracted through a dust collection port, eliminating most of the dust, preventing potential dust explosion hazards, and keeping the internal structure clean.