China Precision V Groove Shearing Machine Manufacturers, Suppliers, Factory

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our firm for the long-term to create jointly with consumers for mutual reciprocity and mutual reward for Precision V Groove Shearing Machine,Automatic V Groove Notcher,Automatic V Groove Welding System,Precision V Groove Welding Equipment,Steel Sheet V Groove Bending Machine, Being a young escalating company, we might not the top, but we're trying our best to generally be your superior partner.

Precision V Groove Shearing Machine, The credibility is the priority, and the service is the vitality. We promise we now have the ability to supply excellent quality and reasonable price products and solutions for customers. With us, your safety is guaranteed.

Hot Products

Horizontal High Speed V Groove Slotting Machine

JM is professional v slotting machine manufacturer in China, its horizontal high speed v groove slotting machine is a durable V grooving equipment, this machine have high cost-effectiveness and economic benefits at medium to low utilization rates.Horizontal High Speed V Cutting Machine For Metal Plates

The Chinese manufacturer JM produces the horizontal high speed V cutting machine for metal plates, it is applicable to all metal plates, such as stainless steel plates, copper plates, galvanized plates and so on.Vertical High Speed Slotting Machine

The vertical high speed slotting machine from Chinese V grooving machine manufacturer JM is a professional V grooving equipment, this machine can bring good economic benefits in processing of mirror plates.Four Side V Grooving Machine

A metal sheet v grooving machine can create V-shaped grooves in stainless steel sheets, aluminum sheets, composite aluminum sheets, copper sheets, and other metal plates. Four side v grooving machine realize the horizontal grooving of the plate. This allows the bent workpieces to have a very small edge radius, meeting the high precision and aesthetic demands of the high-end sheet metal decoration industry.CNC Guillotine Shearing Machine

JM CNC Guillotine Shearing Machine is a commonly used shearing device in metal processing, primarily designed for cutting metal sheets of various thicknesses. It operates by applying a vertical downward motion of the upper blade against the lower blade, generating a shearing force to achieve precise cutting. It is mainly used for high-precision shearing of metal materials such as steel plates, stainless steel, and aluminum sheets. The shearing machine is widely applied in industries such as machinery manufacturing, automotive production, and electrical equipment manufacturing. The shearing method of the JM Guillotine Shearing Machine is similar to a "gate" moving up and down. Using hydraulic or mechanical transmission, the upper blade holder moves linearly downward along a fixed track (usually vertical or at an inclined angle) to shear metal sheets. With high shearing precision, it is especially suitable for cutting thick plates. JM shearing machine is designed for sheet metal processing, providing high-precision cutting solutions suitable for various metal sheets.Wet Deburring & Brushing Machine

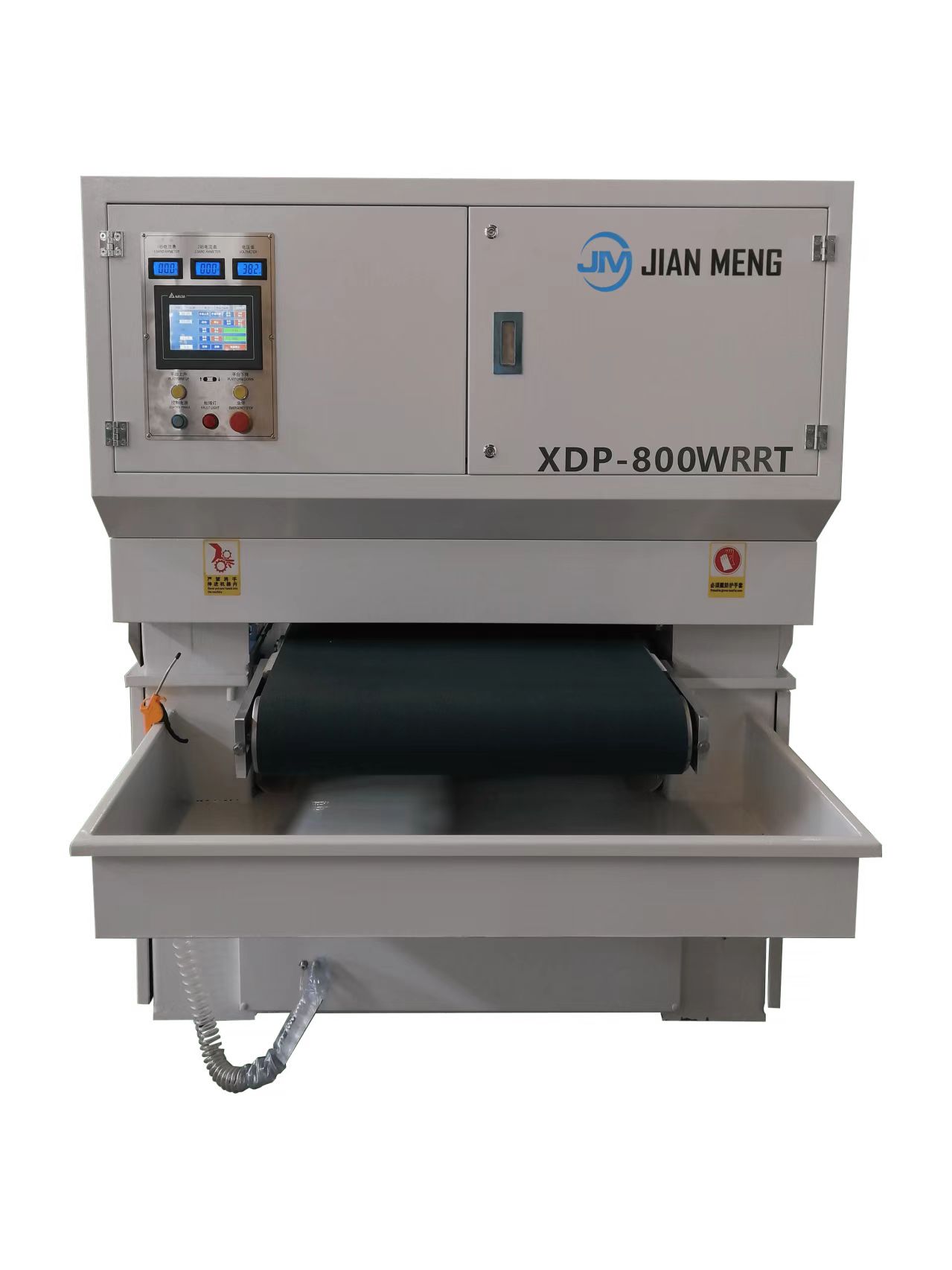

JM Wet Deburring Machine is a specialized solution for removing burrs, slag, oxide layers, and sharp edges from metal sheets and plates. It operates using wide abrasive belts under wet conditions, ensuring clean, uniform surface finishing without producing harmful dust. This machine is ideal for improving surface quality after laser, plasma, or shear cutting. Featuring a dual abrasive belt structure, the metal finishing machine delivers high-speed, consistent material removal across a wide working width. Automatic deburring machine process cools the material during grinding, prevents thermal deformation, and enhances the lifespan of consumables. Its built-in filtration and water circulation system ensures clean operation and easy maintenance. Suitable for stainless steel, aluminum, copper, the deburring equipment for metal sheet is widely used in industries such as kitchenware, electronics, and general metal fabrication. Compared to dry processing, it offers superior surface results, improved workplace safety, and a more environmentally friendly production process.