- Horizontal V Grooving Machine

- Vertical V Grooving Machine

- Automatic Four Side V Grooving Machine

- V Grooving Machine Accessory

- Metal Forming Machine

- Deburring Machine

- Thin Sheet Deburring Machine

- Abrasive Belt Deburring Machine

- Carbon Steel Deburring Machine

- Deburring and Brushing Machine

- Manual Deburring Machine

- Wet Dust Collector

- Deburring Polishing & Brushing Machine

- Deburring & Chamfering Machine

- Wet Deburring & Brushing Machine

- Deburring, Edge rounding & Polishing Machine

- Carbon Steel Deburring & Brushing & Edge rounding Machine

- Dry Deburring, Brushing, and Polishing Machine

- Deburring and Brushing Machine with Slag Hammer Disc

- Shearing Machine

- Press Brake

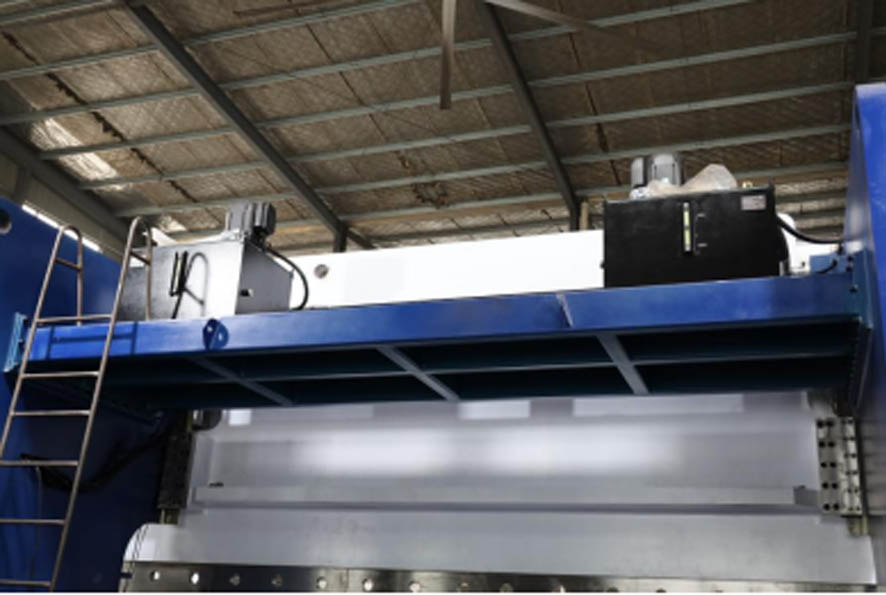

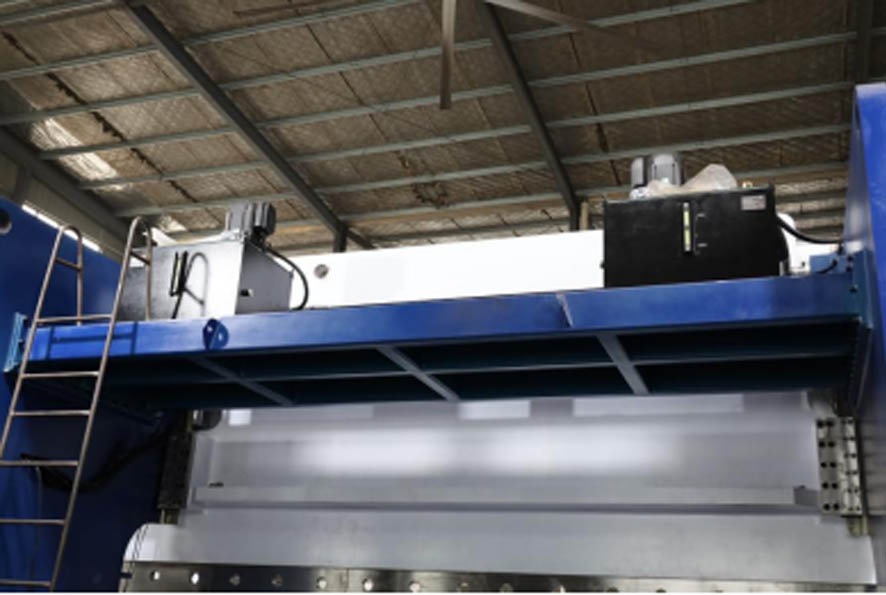

Electro-Hydraulic Dual Servo Pump CNC Press Brake

This Electro-Hydraulic Dual Servo Pump CNC Press Brake is a high-performance, intelligent machine for sheet metal bending. Its core advantage is the energy-saving dual-servo pump system, which cuts electricity costs significantly. It guarantees extreme precision and consistent quality with automatic real-time adjustments, even for off-center parts. Built for stability and ease of use, it is a reliable and cost-effective solution for efficient manufacturing.

Model:130t/3200

Send Inquiry

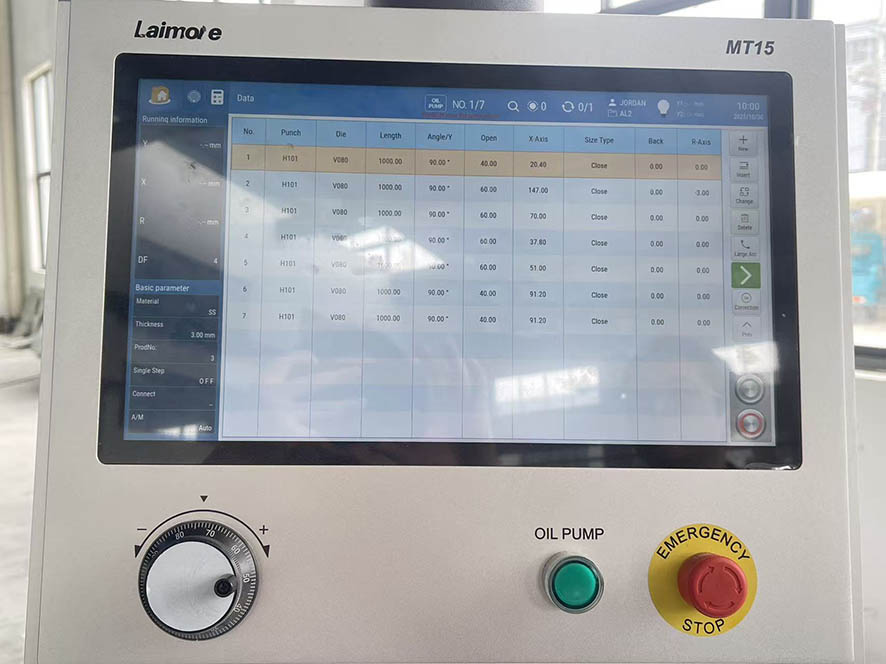

CNC System: Laimore MT15

The CNC system of a press brake is the brain of the entire machine, responsible for controlling the ram, backgauge, and worktable compensation to ensure precise bending angles, dimensions, and positioning. It serves as the core control unit of the press brake, automatically managing the movement of each axis based on the programmed bending parameters to achieve accurate and efficient bending operations.

Hydraulic Station

In a dual servo pump bending machine, the two independent Hydraulic Power Units (HPUs) are key to its high performance. They form an intelligent power system that precisely controls the left and right cylinders separately. The core function of these two HPUs is to enable precise digital control over the ram's speed, position, and synchronization through the servo system, ensuring high accuracy and consistency in bending operations. Moreover, this on-demand oil supply mechanism significantly reduces energy consumption and operating noise compared to traditional hydraulic systems.

Servo Motor: China INOVANCE

The servo motor is one of the key driving components of the entire system, used to precisely control the movement of the ram in the hydraulic system. It is a high-precision and controllable motor that can accurately adjust speed, position, and torque according to control signals, and is widely used in CNC machinery.

Ball Screw&Linear Guide

The ball screw is a key transmission component in the backgauge system, used to achieve high-precision linear positioning and movement. It enables the backgauge system to maintain stable, fast, and accurate motion during the bending process, serving as an essential foundation for the high-performance operation of the press brake.

The linear guide is an essential component of the backgauge system and the ram guiding mechanism, designed to ensure that all moving parts travel smoothly and accurately along a straight path. It allows the machine to operate more smoothly, precisely, and durably during the bending process, making it a fundamental structure indispensable to modern CNC press brakes.

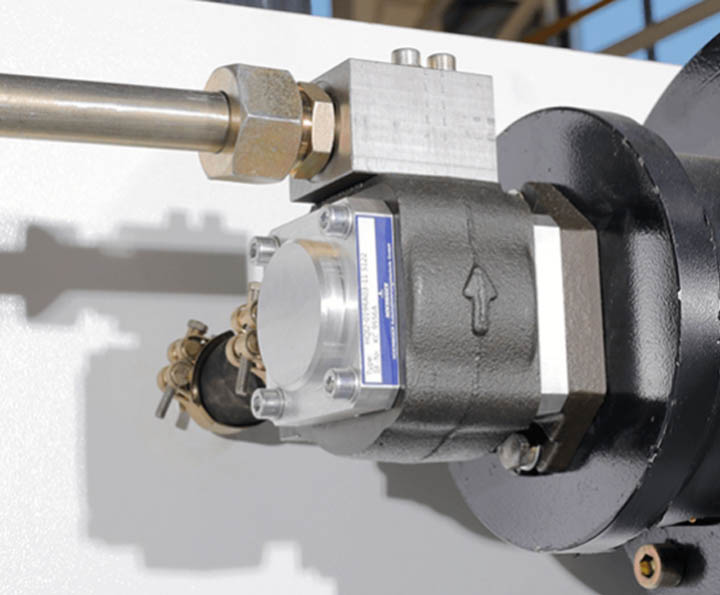

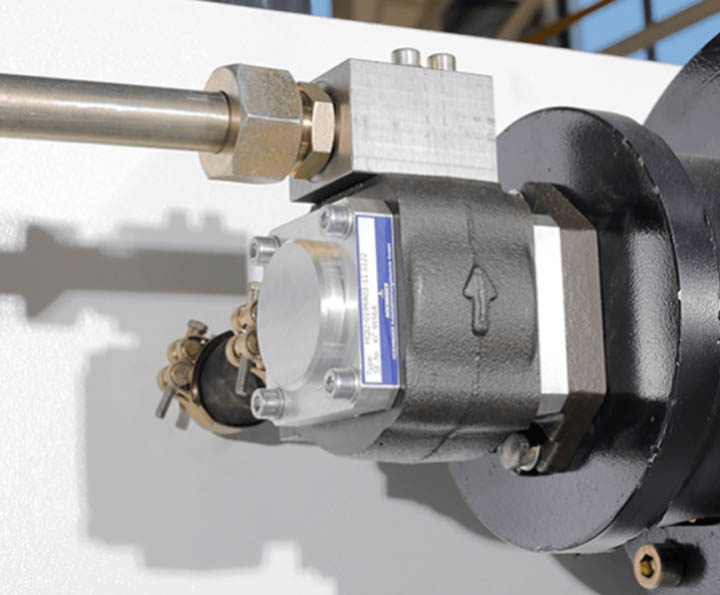

Internal Gear Pump

An internal gear pump is the "heart" of the press brake's hydraulic system. It uses two interlocking gears—one inside the other—to suck in and push out hydraulic oil. This action creates the powerful, smooth flow of oil needed to move the machine's slider and generate bending force. It's known for being efficient, compact, and reliable.

Product Specifications

|

Category |

Item |

Specification |

|

Basic Parameters |

Nominal Pressure |

1300 kN |

|

|

Bending Length |

3200 mm |

|

|

Slider Stroke |

200 mm |

|

|

Throat Depth |

400 mm |

|

Working Speed |

Fast |

180 mm/s |

|

|

Normal |

10mm/s |

|

|

Return |

180 mm/s |

|

CNC System |

Number of Control Axes |

4 + 1 |

|

|

X-Axis Stroke |

600 mm |

|

|

Main Motor Power |

2x6 kW |

Configuration List

All of our component suppliers are globally recognized brands, guaranteeing dependable quality and seamless after-sales support.

Products & Services

We are committed to your machine's entire lifecycle. Our global team provides 24/7 support and rapid spare parts delivery to minimize downtime. We also offer equipment upgrades and preventative maintenance plans to enhance performance, extend longevity, and protect your investment.

Application

In the construction industry, theElectro-Hydraulic Dual Servo Pump CNC Press Brake is primarily used for precisely processing metal structural components, such as load-bearing beams and columns for steel frames, metal support keels for curtain walls, as well as various ventilation ducts and decorative panels. Its core value lies in its ability to efficiently bend extra-long sheets in a single operation, thanks to the precise synchronization control of the ram by its two independent hydraulic power units. This ensures highly consistent bend angles along the entire length of the component, effectively preventing on-site installation issues caused by component twisting or angular deviations. Consequently, it guarantees the structural safety, construction efficiency, and final aesthetic quality of large-scale building projects from the very source.