- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Hydraulic shearing machine for sheet metal fabrication Manufacturers, Suppliers, Factory

The key to our success is "Good Product Quality, Reasonable Value and Efficient Service" for Hydraulic shearing machine for sheet metal fabrication,Metal Shearing Machine,Hydraulic Shearing Machine,CNC Shearing Machine,Guillotine Shearing Machine, We warmly welcome all intrigued shoppers to make contact with us for more data.

Hydraulic shearing machine for sheet metal fabrication, Our expert engineering team will generally be prepared to serve you for consultation and feedback. We're able to also give you with free of charge samples to meet your requirements. Best efforts will likely be produced to provide you the best service and merchandise. When you are keen on our business and items, make sure you speak to us by sending us emails or call us quickly. In an effort to know our merchandise and company extra, you may come to our factory to view it. We'll generally welcome guests from all over the world to our business to create business relations with us. Be sure to feel cost-free to speak to us for small business and we believe we are going to share the best trading experience with all our merchants.

Hot Products

Horizontal Double Drive V Cutting Machine

The Chinese professional manufacturer of V grooving machine JM has excellent equipment and after-sales service, the horizontal double drive V cutting machine from it supports fixed-point V-shaped cutting.Horizontal Double Drive V Slotting Machine

As the professional V grooving machine manufacturer in China, JM produces the cost-effective horizontal double drive V slotting machine for processing metal plates, this machine is easy to master and operate.Deburring and wire drawing machine

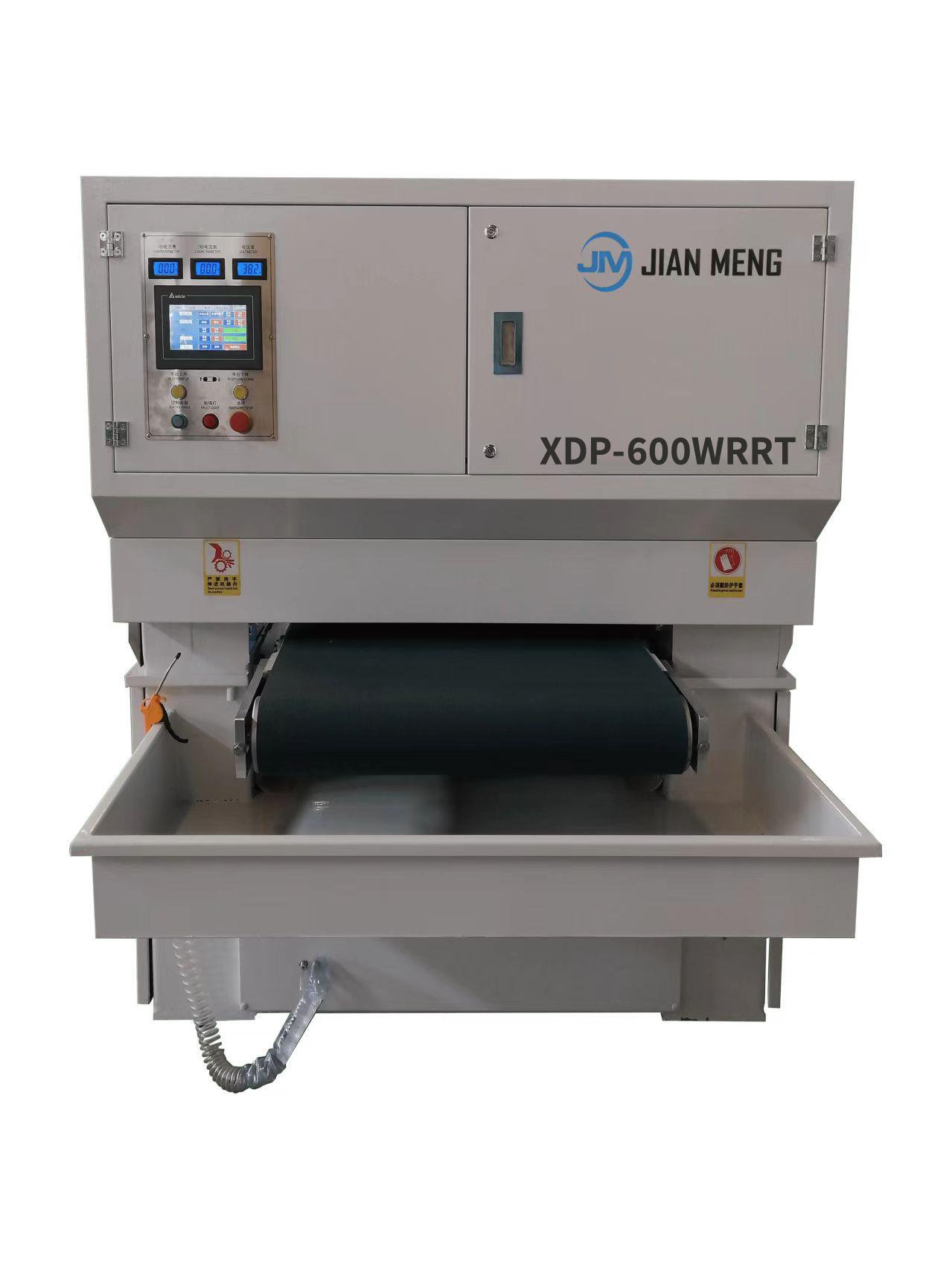

JM is a leading manufacturer specializing in deburring and wire drawing machine. A deburring machine is a piece of equipment used in the metal processing and manufacturing industry, primarily designed to remove burrs, sharp edges, and oxide layers from workpieces, thereby improving product quality and safety. The XDP-800RPR Deburring & Brushing Machine is a highly integrated and intelligent metal surface treatment system, specifically designed for efficient deburring, chamfering, and brushing processes. Independently developed by Jianmeng, the deburring machine ensures stability and processing precision under complex working conditions through dynamic simulation and process optimization. JIANMENG offers various solutions to enhance the efficiency of metal fabrication!CNC Deburring and Wire Drawing Machine

JM is a leading manufacturer specializing in CNC Deburring and Wire Drawing Machine.CNC Deburring and Wire Drawing Machine is a highly efficient and intelligent device that integrates deburring, chamfering, oxide layer removal, and metal surface brushing. Deburring and Wire Drawing Machine is widely used in sheet metal processing, automotive manufacturing, and precision instrument industries. Deburring and Brushing Machine effectively removes burrs, sharp edges, and flash from workpieces, ensuring smooth edges. Deburring Polishing Machine is suitable for surface treatment of stainless steel, carbon steel, copper, and other metal materials. JM Deburring and Wire Drawing Machine, with its high efficiency, stability, and intelligent features, provides a one-stop surface treatment solution for metal processing enterprises. Whether it is improving workpiece quality or enhancing production efficiency, this machine meets all processing demands, making it an essential piece of equipment for modern manufacturing.CNC Wet Metal Deburring & Brushing & Polishing Machine

JM Wet Deburring Machine is a high-performance solution designed to efficiently remove burrs, slag, oxide layers, and sharp edges from metal sheets and plates. Utilizing wide abrasive belts in a wet processing environment, it delivers smooth, consistent surface finishes while eliminating harmful dust emissions. This makes it especially effective for post-processing after laser cutting, plasma cutting, or shearing. Equipped with a dual abrasive belt system, the machine ensures fast and uniform material removal across large surfaces. The wet grinding process not only cools the metal during operation—preventing heat-related distortion—but also extends the life of consumables. Its integrated filtration and water recirculation system supports clean, low-maintenance operation. Engineered for materials like stainless steel, aluminum, and copper, this sheet metal deburring machine is widely used in sectors including kitchen appliance manufacturing, electronics, and general metalworking. Compared to dry processing methods, it provides better surface quality, enhances workplace safety, and promotes environmentally responsible manufacturing.Electro-Hydraulic Synchronous CNC Bending Machine

The Press Brake is a sophisticated and intelligent sheet metal forming system designed to meet diverse fabrication needs. Its structural framework, developed by JIANMENG Smart, utilizes PRO/E 3D modeling and finite element analysis (FEA) to ensure optimal frame strength and rigidity according to international standards. Made from premium Q235B steel, the frame is treated with shot blasting, anti-corrosion coating, and vibration stress-relief processes to improve mechanical stability, durability, and long-term reliability.