- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Horizontal V Grooving Machine

- Vertical V Grooving Machine

- Automatic Four Side V Grooving Machine

- V Grooving Machine Accessory

- Metal Forming Machine

- Deburring Machine

- Thin Sheet Deburring Machine

- Abrasive Belt Deburring Machine

- Carbon Steel Deburring Machine

- Deburring and Brushing Machine

- Manual Deburring Machine

- Wet Dust Collector

- Deburring Polishing & Brushing Machine

- Deburring & Chamfering Machine

- Wet Deburring & Brushing Machine

- Deburring, Edge rounding & Polishing Machine

- Carbon Steel Deburring & Brushing & Edge rounding Machine

- Shearing Machine

- Press Brake

Electro-Hydraulic Synchronous CNC Bending Machine

The Press Brake is a sophisticated and intelligent sheet metal forming system designed to meet diverse fabrication needs. Its structural framework, developed by JIANMENG Smart, utilizes PRO/E 3D modeling and finite element analysis (FEA) to ensure optimal frame strength and rigidity according to international standards. Made from premium Q235B steel, the frame is treated with shot blasting, anti-corrosion coating, and vibration stress-relief processes to improve mechanical stability, durability, and long-term reliability.

Model:130T/3200

Send Inquiry

CNC System: Laimore MT15

The CNC system of a press brake is the brain of the entire machine, responsible for controlling the ram, backgauge, and worktable compensation to ensure precise bending angles, dimensions, and positioning. It serves as the core control unit of the press brake, automatically managing the movement of each axis based on the programmed bending parameters to achieve accurate and efficient bending operations.

Hydraulic Valve Group:

The hydraulic valve group is the core control component of the hydraulic system, mainly responsible for regulating the flow direction, pressure, and flow rate of hydraulic oil to achieve precise movement and synchronized control of the ram. It operates according to the control signals from the CNC system, coordinating the flow and pressure distribution of the hydraulic oil to ensure ram synchronization, precise bending, and safe operation.

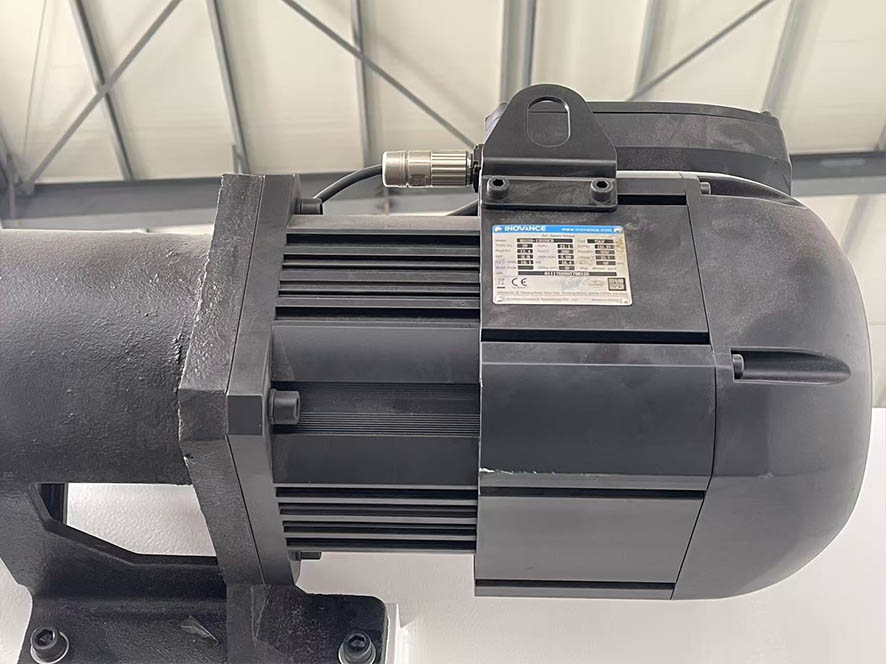

Servo Motor: China INOVANCE

The servo motor is one of the key driving components of the entire system, used to precisely control the movement of the ram in the hydraulic system. It is a high-precision and controllable motor that can accurately adjust speed, position, and torque according to control signals, and is widely used in CNC machinery.

Ball Screw&Linear Guide:Taiwan Hiwin

The ball screw is a key transmission component in the backgauge system, used to achieve high-precision linear positioning and movement. It enables the backgauge system to maintain stable, fast, and accurate motion during the bending process, serving as an essential foundation for the high-performance operation of the press brake.

The linear guide is an essential component of the backgauge system and the ram guiding mechanism, designed to ensure that all moving parts travel smoothly and accurately along a straight path. It allows the machine to operate more smoothly, precisely, and durably during the bending process, making it a fundamental structure indispensable to modern CNC press brakes..)

Quick Clamp

The quick clamp is a specialized mechanism designed for the rapid installation and replacement ofpunching on press brakes. It significantly reduces tool changeover time, enhances production efficiency, and ensures high precision and operational safety during clamping operations.

Back Gauge

The backgauge is an essential component used to position sheet metal workpieces for bending. It utilizes a servo motor-driven ball screw or linear guide system to achieve high-precision adjustment and repeatable positioning of the workpiece.

3. Product Specifications

Category

Item

Specification

Basic Parameters

Nominal Pressure

1300 kN

Workbench Length

3200 mm

Slider Stroke

200 mm

Throat Depth

500 mm

Working Speed

Fast

160 mm/s

Normal

10 mm/s

Return

130 mm/s

CNC System

Number of Control Axes

4 + 1

X-Axis Stroke

20–600 mm

Main Motor Power

11 kW

3. Configuration List

All of our component suppliers are globally recognized brands, guaranteeing dependable quality and seamless after-sales support.

Structural Design

The bending machine structure, designed by JIANMENG Smart, employs PRO/E 3D simulation and finite element analysis to guarantee the frame’s strength and stiffness, complying with industry standards. The Hydraulic Press Brake frame is constructed from Q235B steel and treated with shot blasting, anti-corrosion coating, and vibration stress-relief processes, enhancing its durability and stability.

Precision Processing

The structure of the hydraulic bending machine consists of the worktable, slider, and side panels, all machined using a large CNC system to guarantee accuracy. The slider and worktable are coordinated via an electro-hydraulic servo system, featuring real-time error detection and dynamic correction to ensure precise operation. This level of precision enables the Press Brake to perform complex bending tasks under uneven loads while maximizing product yield.

Products & Services

JIANMENG offers advanced machinery along with comprehensive after-sales support. From project planning and production supervision to operator training, maintenance, and spare parts provision, we provide complete end-to-end services to guarantee peak performance and efficiency.

Application

Home Appliance Industry

The hydraulic bending machine is extensively applied in the home appliance sector for producing metal housings and internal sheet metal parts of appliances like refrigerators, washing machines, air conditioners, microwave ovens, and electric ovens. Equipped with a high-precision electro-hydraulic servo control system, the press brake can execute complex, multi-angle bending operations, guaranteeing precise dimensions and smooth surfaces, thereby delivering both excellent appearance and reliable structural support for household appliances.

Construction Industry

The hydraulic bending machine is primarily utilized in the construction industry for shaping a variety of metal components, including curtain wall panels, steel structure supports, door and window frames, stair handrails, and roof decorations. Featuring a high-precision electro-hydraulic servo control system, the machine allows efficient handling of complex bends and large metal sheets, ensuring both dimensional accuracy and high-quality surface finishes.

Decorative Industry

The hydraulic press brake finds extensive application in the decoration industry for fabricating various metal decorative elements, including stainless steel panels, metal ceilings, door edge covers, and decorative trims. The hydraulic bending machine delivers precise bending and intricate shaping, producing smooth, visually appealing surfaces that enhance the overall decorative effect. Thanks to the stable control of its hydraulic system, the machine operates reliably with high forming accuracy, making it well-suited for architectural and interior decoration projects.