- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Horizontal DOUBLE DRIVE V Grooving Machine Manufacturers, Suppliers, Factory

Our goal is to satisfy our customers by offering golden service, good price and high quality for Horizontal DOUBLE DRIVE V Grooving Machine,High-Precision V Groove Cutter,Automatic Four Side V Grooving Machine, Our products are strictly inspected before exporting , So we gain a good reputation all over the world. We looking forward to cooperation with you in the future.

Horizontal DOUBLE DRIVE V Grooving Machine, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we are going to continue to develop, to supply the high-quality merchandise and services, and promote lasting cooperation with our customers, common development and create a better future.

Hot Products

Horizontal Double Drive V Slotting Machine For Metal Plates

The Chinese manufacturer JM has been at forefront of Horizontal Double Drive V Slotting Machine For Metal Plates manufacturing, with technological innovation as its core advantage. The horizontal double dive V slotting machine for metal plates is efficient.Vertical Back And Forth V Cutting Machine

The professional V cutting machine manufacturer and supplier JM in China offer customer from all over the world the excellent vertical back and forth V cutting machine. The vertical back and forth cutting machine have all characteristics of traditional V cutting machine.Four Side CNC V Grooving Machine

JM is a leading China Four Side CNC V Grooving Machine manufacturer. A metal sheet v grooving machine can create V-shaped grooves in stainless steel sheets, aluminum sheets, composite aluminum sheets, copper sheets, and other metal plates. Four side v grooving machine realize the horizontal grooving of the plate. This allows the bent workpieces to have a very small edge radius, meeting the high precision and aesthetic demands of the high-end sheet metal decoration industry. JIANMENG provides various solutions, making metal fabrication easier!Horizontal CNC V Groove Machine for Metal Sheet

High quality Horizontal CNC V Groove Machine for Metal Sheet is offered by China manufacturer JM. A metal sheet cnc v grooving machine can create V-shaped grooves in stainless steel sheets, aluminum sheets, composite aluminum sheets, copper sheets, and other metal plates. Our cnc v cut machine allows the bent workpieces to have a very small edge radius, meeting the high precision and aesthetic demands of the high-end sheet metal decoration industry. JIANMENG provides various solutions, making metal fabrication easier!Metal Guillotine Shearing Machine

The JM Metal Guillotine Shearing Machine is a widely used metal processing tool designed for cutting metal sheets of different thicknesses. It functions by driving the upper blade in a vertical downward motion against the stationary lower blade, creating a shearing force for precise cutting. JM Guillotine Shearing Machine is particularly effective for accurately shearing materials such as steel plates, stainless steel, and aluminum sheets. Shearing Machine finds extensive application in industries like machinery manufacturing, automotive production, and electrical equipment manufacturing. The JM Metal Guillotine Shearing Machine utilizes hydraulic power to drive the upper blade holder along a predetermined path in a straight downward motion, ensuring efficient cutting. With its exceptional shearing precision, this machine is especially suitable for processing thick metal plates. Engineered for sheet metal processing, the JM shearing machine delivers high-precision cutting solutions for various types of metal sheets, ensuring accuracy and efficiency in industrial applications.Wet Metal Deburring & Brushing & Polishing Machine

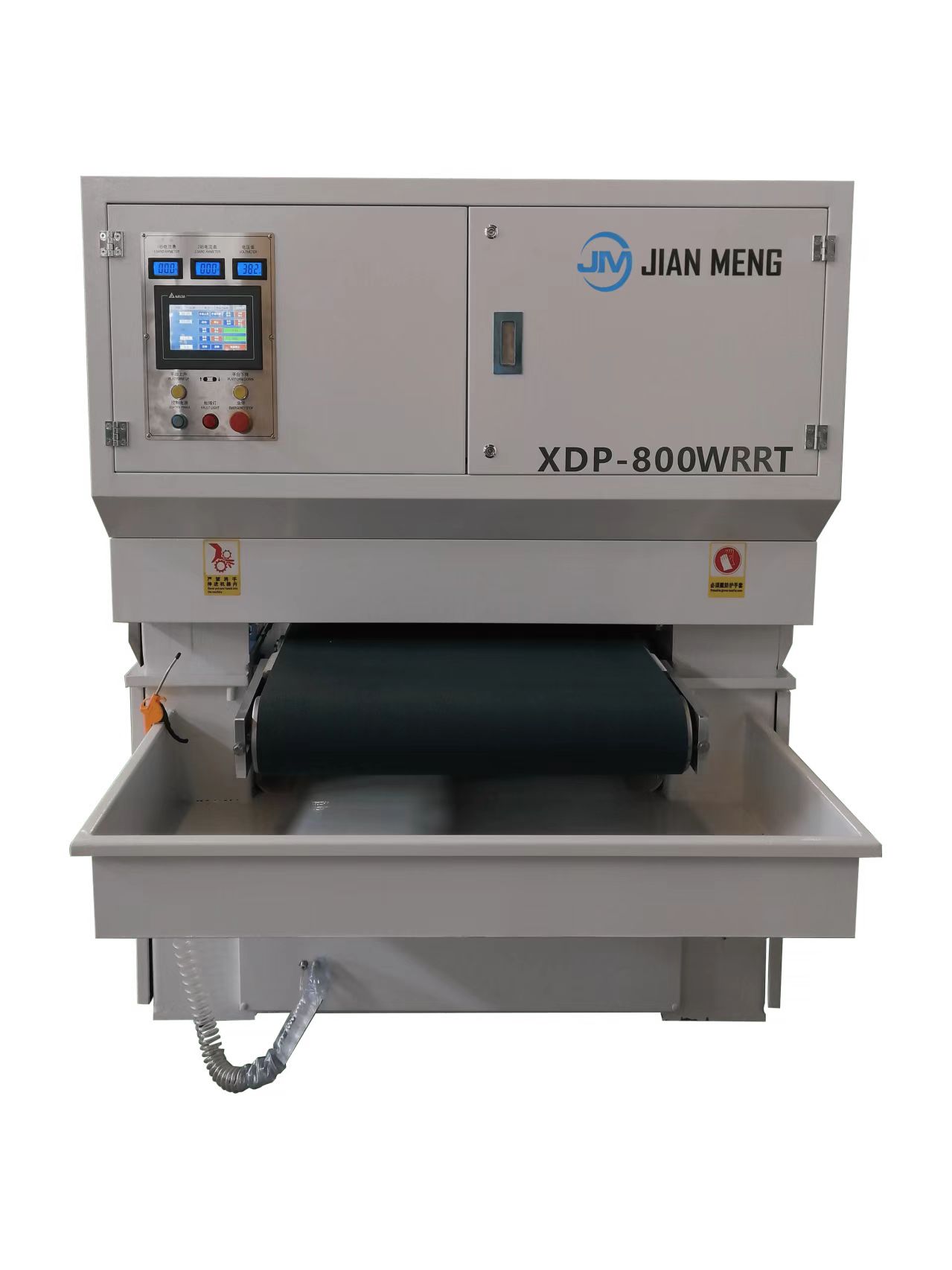

JM Wet Deburring Machine is a high-performance solution designed to efficiently remove burrs, slag, oxide layers, and sharp edges from metal sheets and plates. Utilizing wide abrasive belts in a wet processing environment, it delivers smooth, consistent surface finishes while eliminating harmful dust emissions. This makes it especially effective for post-processing after laser cutting, plasma cutting, or shearing. Equipped with a dual abrasive belt system, the machine ensures fast and uniform material removal across large surfaces. The wet grinding process not only cools the metal during operation—preventing heat-related distortion—but also extends the life of consumables. Its integrated filtration and water recirculation system supports clean, low-maintenance operation. Engineered for materials like stainless steel, aluminum, and copper, this sheet metal deburring machine is widely used in sectors including kitchen appliance manufacturing, electronics, and general metalworking. Compared to dry processing methods, it provides better surface quality, enhances workplace safety, and promotes environmentally responsible manufacturing.