- Horizontal V Grooving Machine

- Vertical V Grooving Machine

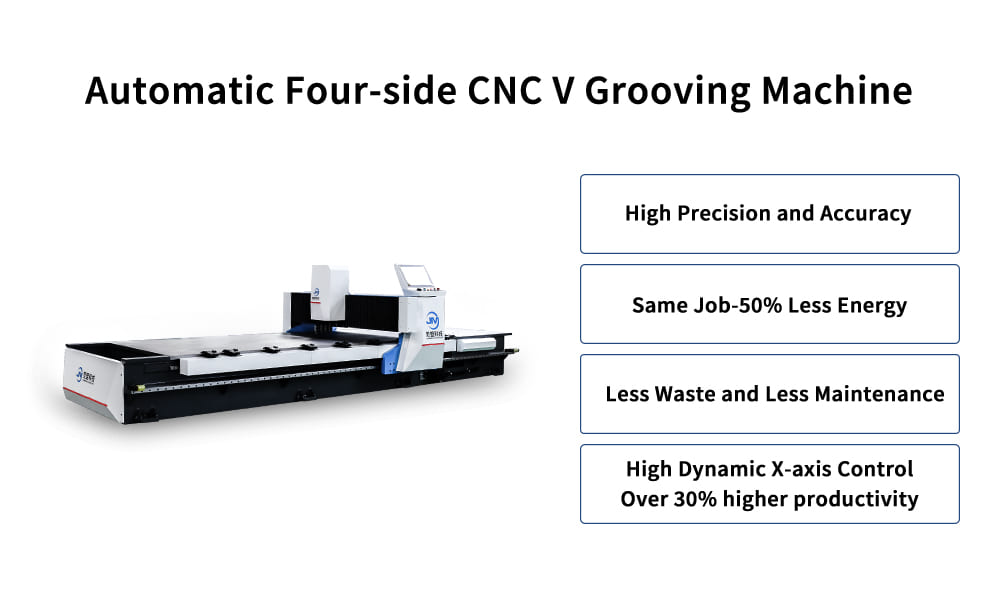

- Automatic Four Side V Grooving Machine

- V Grooving Machine Accessory

- Metal Forming Machine

- Deburring Machine

- Thin Sheet Deburring Machine

- Abrasive Belt Deburring Machine

- Carbon Steel Deburring Machine

- Deburring and Brushing Machine

- Manual Deburring Machine

- Wet Dust Collector

- Deburring Polishing & Brushing Machine

- Deburring & Chamfering Machine

- Wet Deburring & Brushing Machine

- Deburring, Edge rounding & Polishing Machine

- Carbon Steel Deburring & Brushing & Edge rounding Machine

- Dry Deburring, Brushing, and Polishing Machine

- Deburring and Brushing Machine with Slag Hammer Disc

- Shearing Machine

- Press Brake

Vertical Back And Forth V Grooving Machine for Sheet Metal

JM is a leading manufacturer specializing in vertical back and forth v grooving machine for sheet metal in China. The Vertical Back-and-Forth V Grooving Machine precisely cuts V-shaped grooves in stainless steel, aluminum, composite aluminum, copper, and other metal sheets. A metal sheet v grooving machine machine allows workpieces to achieve an extremely small edge radius, perfectly meeting the high precision and aesthetic demands of the high-end sheet metal decoration industry. JIANMENG offers various solutions to enhance the efficiency of metal fabrication!

Model:GSTM 1500×4000 Customized

Send Inquiry

Fixed Clamp

The function of the fixed clamp on CNC vertical back and forth v grooving machine for sheet metal is to securely hold the workpiece in place during the milling or slotting process, preventing any movement or shifting. This ensures precise and consistent cuts, improving the accuracy and quality of the machining process.

Tool holder

In V Cutting Machine , the function of the tool is to support and secure the cutting tool, allowing it to cut along a predetermined path during the machining process. The tool holder is usually adjustable to accommodate different machining requirements, ensuring machining accuracy and cutting performance.

Racks and guide rails

Racks and guide rails provide smooth and stable linear movement for the tool post or worktable, reducing friction and ensuring machining accuracy.

Movable Clamp

In Vertical CNC Grooving Machine, the function of the movable clamp is to adjust according to the different shapes and sizes of the workpiece to better secure it. It can move during the machining process as needed, ensuring that the workpiece does not shift during cutting, thereby improving machining accuracy and stability.

Flexible cable

Flexible cables can withstand the reciprocating motion of components such as the tool post and worktable without easily breaking or getting damaged. They ensure the reliable operation of CNC systems, servo motors, and sensors, enhancing machining accuracy. Made with high-strength protective sheathing, they prevent external wear and reduce electromagnetic interference, improving overall operational stability.

Electrical components

Electrical components supply power to various parts of the v grooving machine, such as the servo motor, CNC system, and sensors, ensuring normal operation of the equipment. They also prevent overloads, short circuits, and other faults through circuit protection devices (such as circuit breakers, fuses, and protective relays), ensuring safe operation of the equipment.

|

Double-head v cut machine Configuration list

|

Controller: EASYCAT |

|

Hydraulic control system: Japan Yuken |

|

|

Servo motor: EASYCAT |

|

|

Single/double pole air switch: France Schneider |

|

|

AC contacter: Schneider-France |

|

|

Bearing: Japan SKF |

|

|

Alloy knife: Chinese |

|

|

Machine tool cable: Germany Igus |

Two Tool Holders

The vertical back-and-forth grooving machine has 6 or 8-tool holders, with dual tool holders for back-and-forth cutting work.

CNC System

·CNC large touch screen

·2D-Drawing function

·Bending effect display

·Remote control function

·Full servo control system

Worktable

CNC V Groove Machine features an open worktable, with double-sided presser feet for firm fixation, and a high-hardness bottom film for mark-free processing.

The back gauge

The back gauge of the Vertical V Grooving Machine is driven by dual screws and rails, providing stable operation and precise positioning, ensuring consistent cutting distances for each pass, thereby improving machining accuracy and efficiency.

The process flow of a vertical v grooving machine:

Raw Material Processing:

· Cut raw materials to ensure dimensions meet design requirements.

· Perform welding to connect components and form the initial structure.

· Apply painting to enhance corrosion resistance and aesthetics.

Machining:

· Use a gantry milling machine for precision machining to improve dimensional accuracy and flatness.

Assembly & Debugging:

· Workshop personnel assemble the processed components into a complete machine or module.

· Perform debugging to ensure proper operation and compliance with design requirements.

Quality Inspection:

· Use instruments to measure accuracy and ensure the equipment meets technical specifications and quality standards.

Shipping & Delivery:

· Load and ship the qualified products to the customer or project site.

Vertical Back And Forth V Grooving Machine Parameter

| Working width and length |

1250/1500-4000mm/customized |

| Thickness range of machinable sheet |

0.4-6mm |

|

Maximum shaft speed parallel to X-axis |

130m/min |

|

X-axis servo motor power |

5.5KW |

|

Axis resolution(X, Y, Z1,Z2) |

0.001mm |

|

Axis positioning accuracy(X, Y, Z1, Z2) |

0.001mm |

Clients’ Grooving Cases:

The vertical back-and-forth v grooving machine, with its high precision, stability, and efficiency, has been widely used in various industries, helping customers improve product quality and optimize processing workflows. This leads to workpieces with better-defined shapes, reduced material distortion, and enhanced overall structural integrity.

Regardless of the material or specifications of the workpieces, our customers can achieve superior bending results. This demonstrates that our CNC V-cut machine not only meets but exceeds their expectations.

Application OF Vertical CNC V Groove Machine for Metal Sheet:

Our CNC grooving machine is widely used in various metal processing industries such as architectural decoration, sanitary ware, kitchenware, door manufacturing, elevator equipment, advertising signage, equipment enclosures, and aluminum curtain walls. Many customers also use this v grooving machine in the automotive manufacturing, machinery, electrical equipment, precision parts, hardware products, and aluminum and copper products industries.