China Electric Press Brake Manufacturers, Suppliers, Factory

Our staff are generally while in the spirit of "continuous improvement and excellence", and while using the excellent high quality merchandise, favorable value and great after-sales services, we try to gain each customer's have faith in for Electric Press Brake,Electric Servo CNC Press Brake,All-Electric Press Brake,Oil-Free Press Brake, Adhering for the enterprise philosophy of 'customer initial, forge ahead', we sincerely welcome consumers from in the home and abroad to cooperate with us.

Electric Press Brake, We always insist on the management tenet of "Quality is first, Technology is basis, Honesty and Innovation".We've been able to develop new products and solutions continuously to a higher level to satisfy different needs of customers.

Hot Products

Horizontal High Speed V Slotting Machine For Metal Plates

The horizontal high speed v slotting machine for metal plates is produced by the professional V slotting machine manufacturer JM in China. It is suitable for all metal plates, such as copper plates, aluminium plates and so on.CNC Vertical High Speedv Grooving Machine

The Chinese V grooving machine manufacturer JM has the most types of CNC Vertical High Speedv Grooving Machine. Its CNC vertical high speed V grooving machine is efficient during mirror plates processing.CNC Carbon Steel Deburring Machine

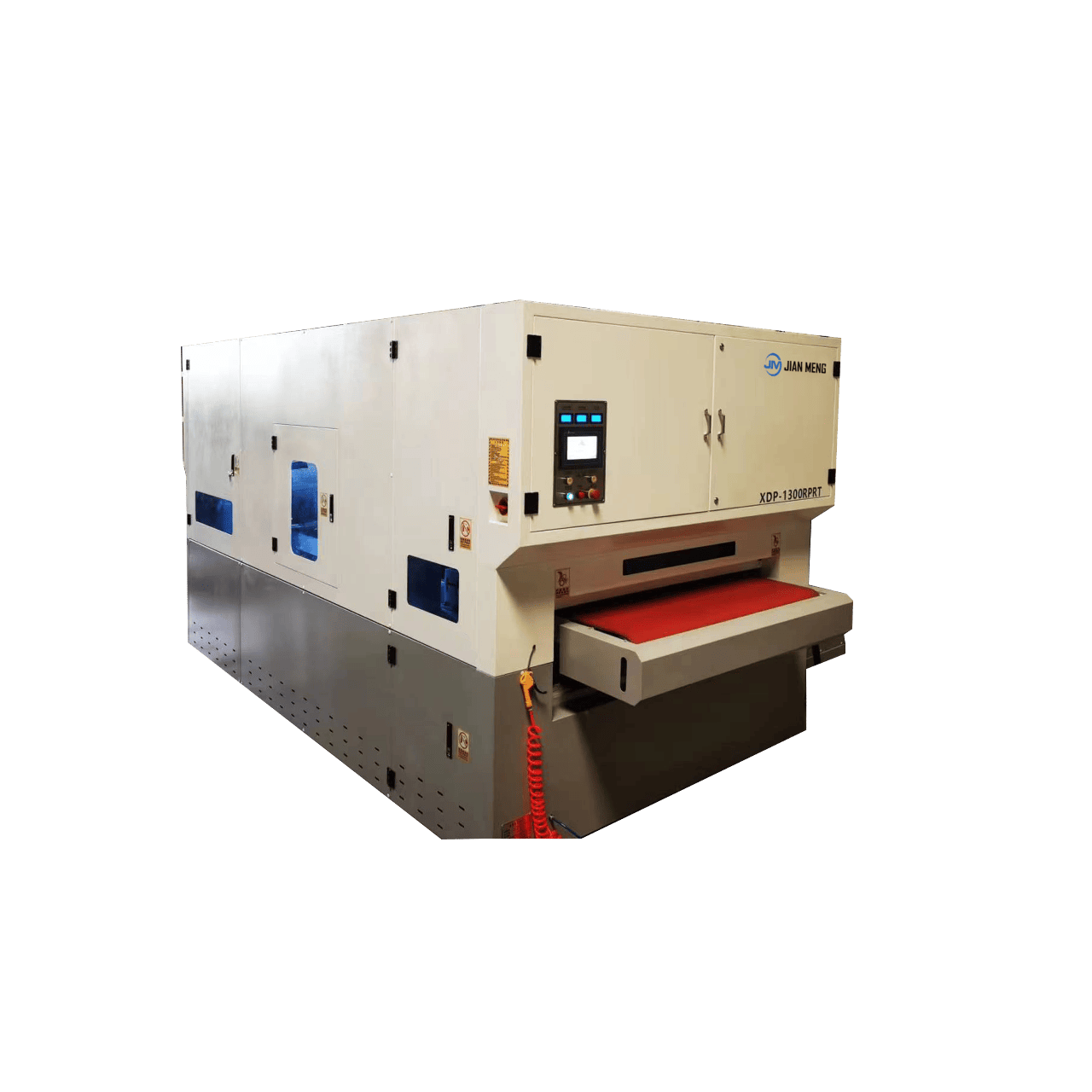

JM is a leading manufacturer specializing in CNC Carbon Steel Deburring Machine. The Carbon Steel Deburring machine is an industrial device specifically designed for removing burrs, sharp edges, and oxide layers from carbon steel parts, plates, and workpieces. Deburring Machine for Carbon Steel Plates is widely used in metal processing, machinery manufacturing, automotive components, Carbon Steel Structure, shipbuilding, and electrical cabinets. JM Carbon Steel Deburring Machine is an efficient deburring, chamfering, and surface finishing equipment specially designed for carbon steel workpieces. It combines advanced technology and high-quality craftsmanship to significantly improve production efficiency while ensuring processing accuracy. Whether used for cutting, stamping, or laser-processed workpieces, the JM Carbon Steel Deburring Machine provides excellent deburring results and ensures that the surface of the workpieces is smooth and flat.Deburring Polishing & Brushing Machine for metal sheet

JM is a leading manufacturer dedicated to developing and producing advanced deburring, polishing, and brushing equipment that meets the highest standards of modern metal surface processing. This efficient and intelligent machine integrates deburring, polishing, oxide removal, chamfering, and surface brushing in one process. Widely used in sheet metal fabrication, automotive parts, and precision instruments, the Industrial Deburring Machine effectively removes burrs, sharp edges, and defects from stainless steel, carbon steel, aluminum, and copper, ensuring smooth and safe edges. Designed for high efficiency, stability, and smart operation, Automatic Deburring Machine enhances workpiece quality, improves consistency, and boosts production speed—providing manufacturers with a reliable, all-in-one surface treatment solution. For superior product quality and streamlined processing, JM’s equipment is the top choice for metalworking enterprises.Electro-Hydraulic Synchronous CNC Bending Machine

The Press Brake is a sophisticated and intelligent sheet metal forming system designed to meet diverse fabrication needs. Its structural framework, developed by JIANMENG Smart, utilizes PRO/E 3D modeling and finite element analysis (FEA) to ensure optimal frame strength and rigidity according to international standards. Made from premium Q235B steel, the frame is treated with shot blasting, anti-corrosion coating, and vibration stress-relief processes to improve mechanical stability, durability, and long-term reliability.Slag Hammer Discs Deburring Polishing & Brushing Machine

The JM disc-brush deburring machine is designed for metal parts after laser cutting, stamping, or flame cutting. Multiple brush discs work together with wide abrasive belts to complete deburring, edge rounding, slag removal, and surface smoothing in a single pass. This creates softer edges and a finer, more uniform finish, enhancing the visual quality and added value of stainless steel, carbon steel, and aluminum workpieces. With a high-rigidity frame and optimized mechanical structure, the machine maintains consistent performance even during long hours of operation. The intelligent control system makes operation simple—brush pressure and processing intensity can be freely adjusted to match different processes. Its wet dust-removal system greatly reduces dust hazards, keeping the workspace safer and cleaner, and making the machine ideal for factory-level continuous production. For enterprises pursuing excellence in metal processing, JM’s technology stands as the trusted choice for achieving flawless results.