- Horizontal V Grooving Machine

- Vertical V Grooving Machine

- Automatic Four Side V Grooving Machine

- V Grooving Machine Accessory

- Metal Forming Machine

- Deburring Machine

- Thin Sheet Deburring Machine

- Abrasive Belt Deburring Machine

- Carbon Steel Deburring Machine

- Deburring and Brushing Machine

- Manual Deburring Machine

- Wet Dust Collector

- Deburring Polishing & Brushing Machine

- Deburring & Chamfering Machine

- Wet Deburring & Brushing Machine

- Deburring, Edge rounding & Polishing Machine

- Carbon Steel Deburring & Brushing & Edge rounding Machine

- Dry Deburring, Brushing, and Polishing Machine

- Deburring and Brushing Machine with Slag Hammer Disc

- Shearing Machine

- Press Brake

Electric Servo CNC Press Brake

The all-electric servo press brake is a high-precision machine for sheet metal forming, featuring a robust alloy steel frame and a pure electric drive system. Utilizing servo motors, ball screws, and optical encoders, it ensures exceptional accuracy and synchronization. This oil-free design offers up to 75% energy savings, faster operation, and includes an intelligent CNC system with automatic deflection compensation for reliable, efficient, and safe high-precision bending tasks.

Model:100t/3200

Send Inquiry

Product Overview

The all-electric servo press brake is a high-precision machine for sheet metal forming, featuring a robust alloy steel frame and a pure electric drive system. Utilizing servo motors, ball screws, and optical encoders, it ensures exceptional accuracy and synchronization. This oil-free design offers up to 75% energy savings, faster operation, and includes an intelligent CNC system with automatic deflection compensation for reliable, efficient, and safe high-precision bending tasks.

CNC System

The integrated control center, specifically designed for electric press brakes. It synchronizes multiple servo motors on the Y-axis through high-resolution optical encoders, enabling precise positioning, force control, and automatic deflection compensation (such as the V-axis) without hydraulic components.

Servo drive

It acts as the bridge between the Controller and the Servo Motor. It receives weak command signals from the Controller (e.g., "rotate the motor 90 degrees") and then converts standard electrical power into controlled, powerful energy that it delivers to the Servo Motor to execute the movement.

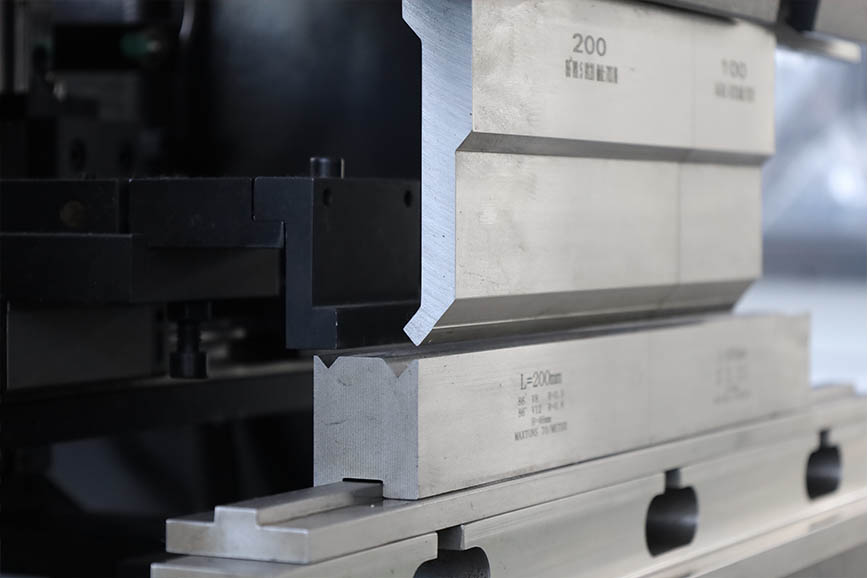

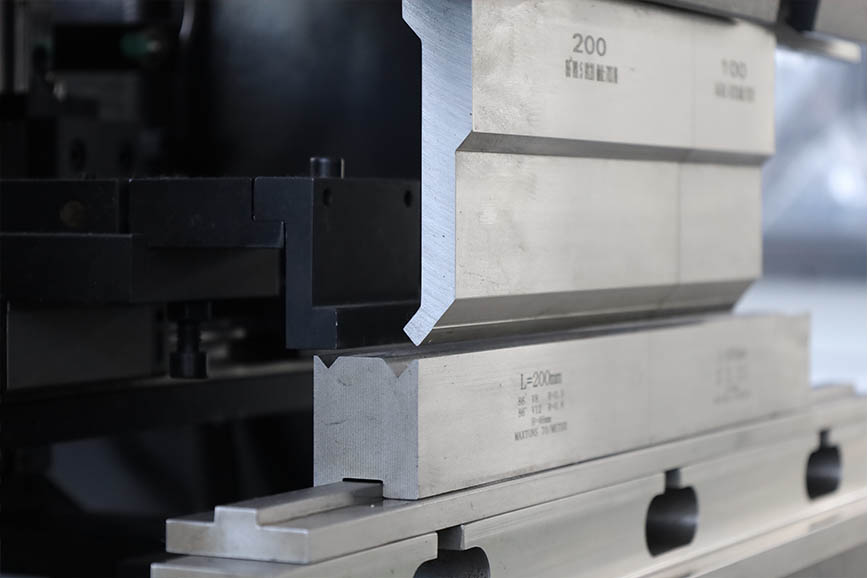

Press brake tooling

Press brake tooling is the core component of a press brake, consisting of a punch and a die. During operation, the punch descends and forces the metal sheet into the V-opening of the die, precisely bending it into the required angle and shape. It is an essential tool for manufacturing various sheet metal components.

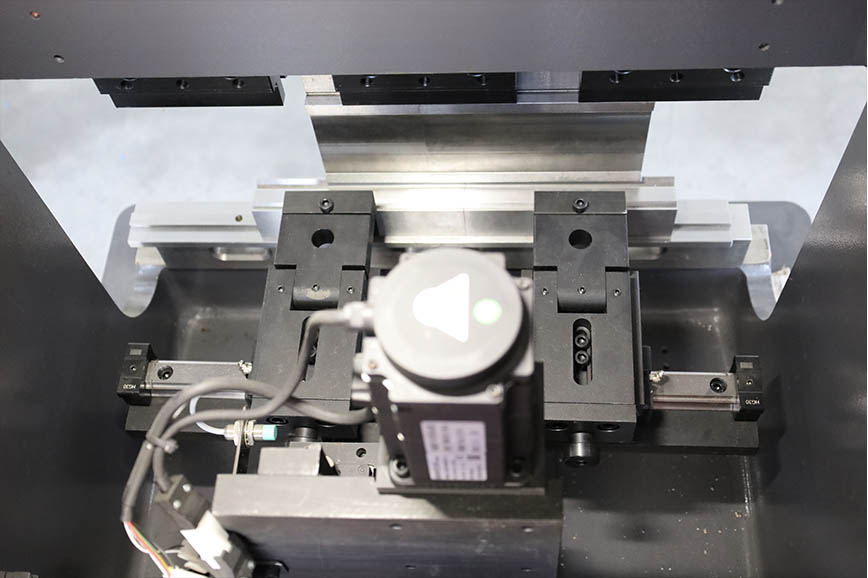

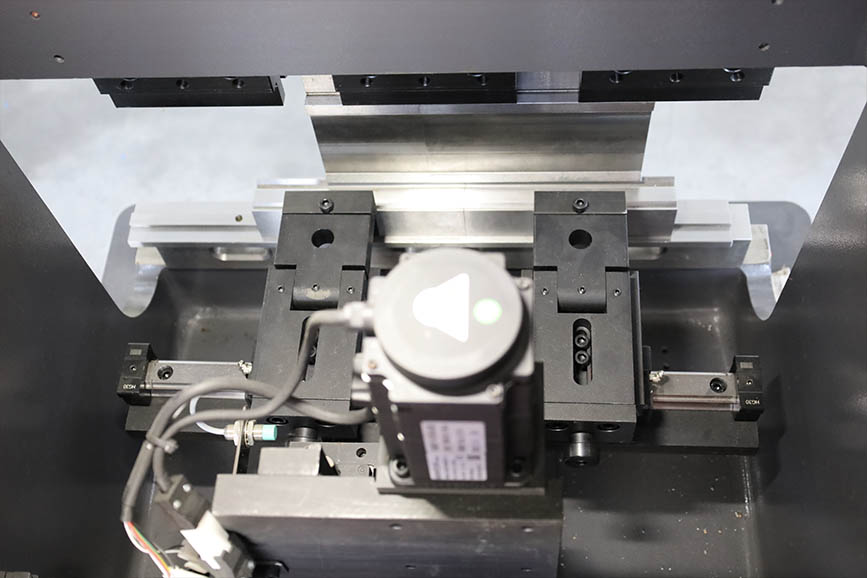

Ball Screw&Linear Guide

The ball screw is a key transmission component in the backgauge system, used to achieve high-precision linear positioning and movement. It enables the backgauge system to maintain stable, fast, and accurate motion during the bending process, serving as an essential foundation for the high-performance operation of the press brake.

The linear guide is an essential component of the backgauge system and the ram guiding mechanism, designed to ensure that all moving parts travel smoothly and accurately along a straight path. It allows the machine to operate more smoothly, precisely, and durably during the bending process, making it a fundamental structure indispensable to modern CNC press brakes.

Back Gauge

The backgauge is an essential component used to position sheet metal workpieces for bending. It utilizes a servo motor-driven ball screw or linear guide system to achieve high-precision adjustment and repeatable positioning of the workpiece.

Quick Clamp

The quick-change clamp on a press brake is an efficient tool-holding device. It utilizes a simple lever or bolt action to securely lock or release the bending dies without traditional tools, significantly reducing tooling setup time and boosting production efficiency and flexibility.

Product Specifications

Category

Item

Specification

Basic Parameters

Nominal Pressure

1000 kN

Bending Length

3200 mm

Slider Stroke

180 mm

Throat Depth

400 mm

Working Speed

Fast

160 mm/s

Normal

30mm/s

Return

160 mm/s

CNC System

Number of Control Axes

4 + 1

X-Axis Stroke

550 mm

Main Motor Power

2x31 kW

Configuration List

All of our component suppliers are globally recognized brands, guaranteeing dependable quality and seamless after-sales support.

Products & Services

JIANMENG delivers not only state-of-the-art machinery but also comprehensive after-sales services. Our support extends across the entire equipment lifecycle—from project design and production supervision to operator training, system maintenance, and spare parts supply—guaranteeing sustained operational efficiency and maximum productivity.

Application

Home Appliance Industry

In the home appliance sector, the electric servo cnc press brake is extensively utilized for producing metal casings and internal sheet metal parts for a range of products including refrigerators, washing machines, air conditioners, microwave ovens, and electric ovens. Equipped with a high-precision electro-hydraulic servo control system, this Press Brake executes intricate multi-angle bending tasks with exceptional accuracy, guaranteeing precise dimensional tolerances and flawless surface quality. This results in household appliances that achieve an optimal balance of aesthetic appeal and robust structural integrity.

Construction Industry

In the construction industry, electric servo cnc press brake are primarily used for shaping diverse metal elements, including curtain wall panels, structural steel supports, frames for doors and windows, staircase handrails, and decorative roofing components. Featuring a high-precision electro-hydraulic servo control system, these machines adeptly handle intricate bending operations and large-format sheet metal, consistently achieving tight dimensional accuracy and excellent surface finish quality.

Decorative Industry

Within the decorative sector, electric servo cnc press brake play a vital role in manufacturing an array of metal ornamentations such as stainless steel panels, metallic ceiling units, door frame edgings, and analogous decorative fittings. These systems excel at performing accurate bending and sophisticated shaping tasks, producing seamless surfaces and refined finishes that enhance the visual quality of decorative installations. Their operation is underpinned by a robust hydraulic control mechanism that guarantees consistent performance and exceptional forming precision, rendering them an optimal choice for both architectural and interior decoration purposes.