China Deburring Machine for Construction Industry Manufacturers, Suppliers, Factory

keep on to improve, to make sure solution good quality in line with market and shopper standard requirements. Our business has a top quality assurance program are actually established for Deburring Machine for Construction Industry,Deburring Machine for Precision Components,Deburring Machine for surface finishing,Deburring Machine for Sheet Metal Fabrication,Deburring Machine for Metalworking, We welcome new and aged consumers to speak to us by telephone or send out us inquiries by mail for long term company associations and attaining mutual results.

Deburring Machine for Construction Industry, For many years, we have now adhered to the principle of customer oriented, quality based, excellence pursuing, mutual benefit sharing. We hope, with great sincerity and good will, to have the honor to help with your further market.

Hot Products

CNC Horizontal High Speed V Grooving Machine

The CNC Horizontal High Speed V Grooving Machine is a stable V grooving equipment produced by JM, the Chinese manufacturer with the most types of V grooving machines. The CNC horizontal high speed V grooving machines is the most cost-effective grooving machine at medium to low utilization rates.Horizontal High Speed V Groove Slotting Machine

JM is professional v slotting machine manufacturer in China, its horizontal high speed v groove slotting machine is a durable V grooving equipment, this machine have high cost-effectiveness and economic benefits at medium to low utilization rates.Horizontal Double Drive V-Shaped Grooving Machine

The horizontal double drive V-shaped grooving machine from the professional v grooving machine manufacturer JM in China, this machine supports fixed-point grooving, processing of dissimilar work.Vertical High Speed V Cutting Machine

The vertical high speed V cutting machine is one of the best-selling grooving machines from Chinese professional V grooving machine manufacturer JM. The vertical high speed V cutting machine is stable and reliable during processing.CNC Thin Sheet Deburring Machine

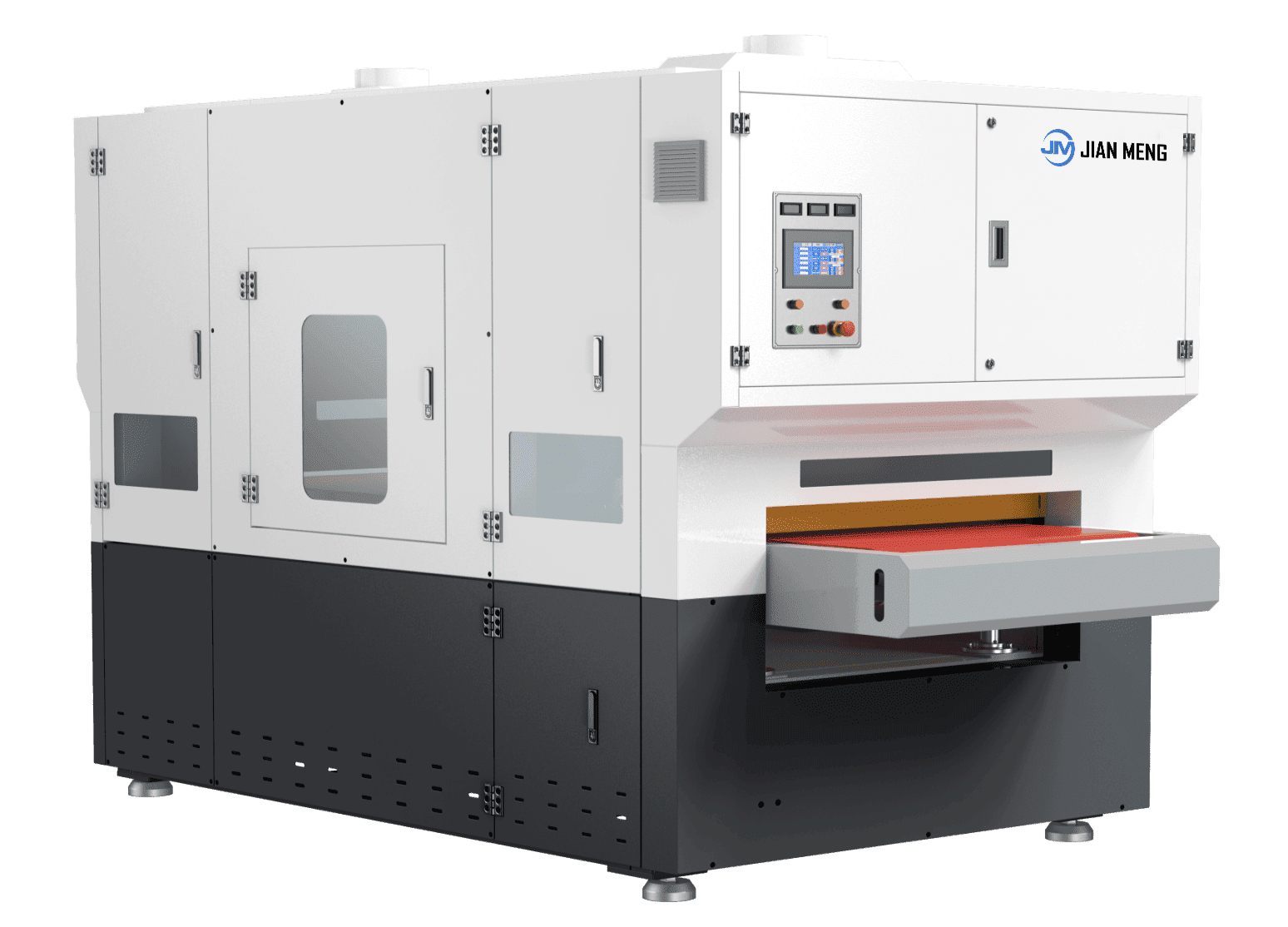

JM is a leading manufacturer specializing in CNC Thin Sheet Deburring Machine.The deburring machine is primarily used for deburring and chamfering the surfaces of various metal workpieces to improve surface quality. The JM deburring machine combines two functions: abrasive belt deburring and roller brush chamfering, allowing multiple surface processing steps to be completed in a single operation, thus enhancing production efficiency and product quality stability. It is suitable for materials such as stainless steel, aluminum alloy plates, steel plates, and copper plates. Different parameters can be adjusted, and appropriate abrasives can be selected based on processing requirements. JM Thin Sheet Deburring Machine, with its high efficiency, stability, and intelligent features, provides a one-stop surface treatment solution for metal processing enterprises. Whether it is improving workpiece quality or enhancing production efficiency, this machine meets all processing demands, making it an essential piece of equipment for modern manufacturing.CNC Carbon Steel Deburring &Brushing& Edge roundingBrushing Machine

The deburring and chamfering machine is specifically designed for surface treatment of carbon steel components. Automatic Deburring Machine features an innovative combination of three sets of wide abrasive belts and six universal rotary brushes for chamfering. This design ensures efficient and precise removal of surface burrs while achieving edge chamfering and surface brushing, significantly improving the surface quality and appearance of the workpiece. The Deburring & Brushing&edge rounding Machine meets the precision and quality requirements of carbon steel surface treatment across various industries, enhancing both production efficiency and product value. Parameters can be adjusted according to different processing needs, and suitable abrasives can be selected accordingly. The metal deburring machine is equipped with one 5.5kW wet dust collector. Dust removal method: The dust generated during operation is effectively extracted through a dust collection port, eliminating most of the dust, preventing potential dust explosion hazards, and keeping the internal structure clean.