China CNC V Groove Notching Machine Manufacturers, Suppliers, Factory

The incredibly rich projects administration experiences and a person to 1 service model make the substantial importance of organization communication and our easy understanding of your expectations for CNC V Groove Notching Machine,V Slotting Machine,V Slotting Grooving Machine,V Groove Notching Machine,V Groove Slotting Machine, We welcome you to inquire us by get in touch with or mail and hope to create a successful and cooperative partnership.

CNC V Groove Notching Machine, With its rich manufacturing experience, high-quality products, and perfect after-sale service, the company has gained good reputation and has become one of the famous enterprise specialized in manufacturing series.We sincerely hope to establish business relation with you and pursue mutual benefit.

Hot Products

Horizontal High Speed V Groove Cutting Machine

The horizontal high speed V groove cutting machine is a professional V groove cutting equipment produced by JM, the Chinese manufacturer with the most types of V groove cutting machines. The horizontal high speed cutting machines have high cost-effectiveness at medium to low utilization rates.Vertical High Speed V Grooving Machine For Stainless Steel Plates

The Vertical High Speed V Grooving Machine For Stainless Steel Plates manufacturer JM in China determines to bring high-quality Chinese manufacturing grooving machines to the world ! The vertical high speed V grooving machine for stainless steel is an upgraded product of traditional grooving machine.Sheet Metal CNC V Grooving Machine

High quality Sheet Metal CNC V Grooving Machine is offered by China manufacturer JM. A metal sheet v grooving machine can create V-shaped grooves in stainless steel sheets, aluminum sheets, composite aluminum sheets, copper sheets, and other metal plates. This allows the bent workpieces to have a very small edge radius, meeting the high precision and aesthetic demands of the high-end sheet metal decoration industry.JIANMENG provides various solutions, making metal fabrication easier!Wet Metal Deburring & Brushing & Polishing Machine

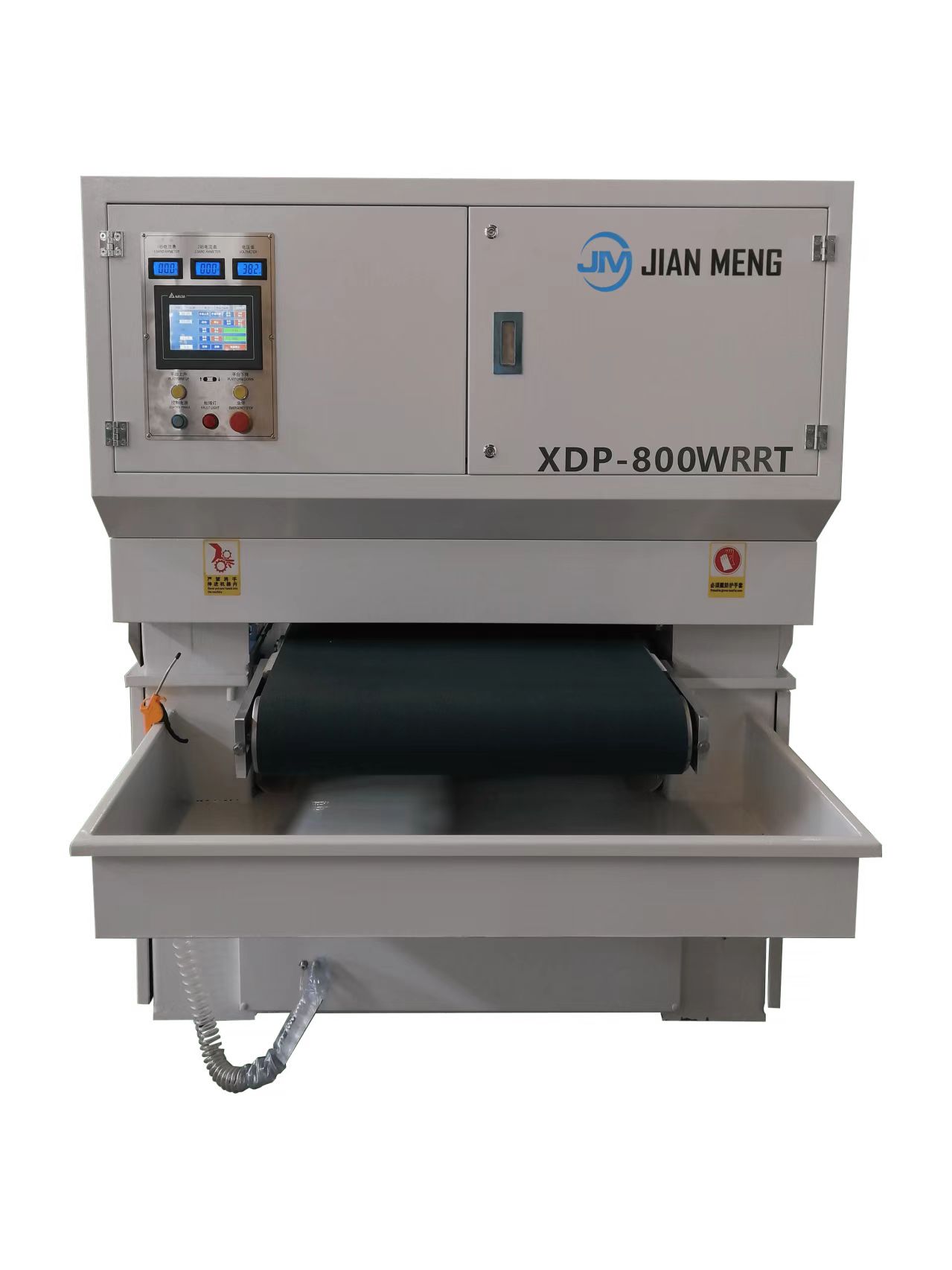

JM Wet Deburring Machine is a high-performance solution designed to efficiently remove burrs, slag, oxide layers, and sharp edges from metal sheets and plates. Utilizing wide abrasive belts in a wet processing environment, it delivers smooth, consistent surface finishes while eliminating harmful dust emissions. This makes it especially effective for post-processing after laser cutting, plasma cutting, or shearing. Equipped with a dual abrasive belt system, the machine ensures fast and uniform material removal across large surfaces. The wet grinding process not only cools the metal during operation—preventing heat-related distortion—but also extends the life of consumables. Its integrated filtration and water recirculation system supports clean, low-maintenance operation. Engineered for materials like stainless steel, aluminum, and copper, this sheet metal deburring machine is widely used in sectors including kitchen appliance manufacturing, electronics, and general metalworking. Compared to dry processing methods, it provides better surface quality, enhances workplace safety, and promotes environmentally responsible manufacturing.Electro-Hydraulic CNC Bending Machine

The Press Brake is a sophisticated and intelligent solution for sheet metal forming, engineered to meet diverse fabrication needs. Its structural frame, designed by JIANMENG Smart, utilizes PRO/E 3D modeling and finite element analysis (FEA) to ensure superior strength and stiffness compliant with global standards. Built from high-grade Q235B steel, the frame is treated with shot blasting, anti-corrosion coatings, and vibration stress-relief processes to improve mechanical stability, service life, and long-term dependability.Manual metal sheet deburring machine

JM manual deburring machine is primarily used for removing burrs from the surface of metal workpieces. Due to its design and operation, the machine is suitable for fine surface deburring and polishing. The manual deburring machine effectively removes surface burrs, ensuring smooth and safe workpieces. It is widely used in sheet metal workpieces for medical devices, kitchenware, refrigerators, and other similar applications. JM manual deburring machine excels in surface deburring of metal workpieces. If your focus is on achieving smooth and high-quality surfaces, it provides an efficient and precise solution.