- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China CNC Press Brake Manufacturers, Suppliers, Factory

We know that we only thrive if we can easily guarantee our combined cost competiveness and high-quality advantageous at the same time for CNC Press Brake,Metal Sheet Plate Hydraulic Press Brake,Hydraulic Press Brake,Mechanical Press Brake,Electric Press Brake, We sincerely be expecting exchange and cooperation with you. Allow us to move forward hand in hand and accomplish win-win circumstance.

CNC Press Brake, During in 11 years, We have now participated in more than 20 exhibitions, obtains the highest praise from each customer. Our company has been devoting that "customer first" and committed to helping customers expand their business, so that they become the Big Boss !

Hot Products

Vertical Back And Forth Cutting Machine

The V cutting machine manufacturer JM in China produces the excellent vertical back and forth cutting machine. The vertical back and forth cutting machine combines with all characteristics of traditional models.Tool Holder

JM is the leading V grooving machine manufacturer in China, it always accompany customers with rich experience, technical strength, good after-sales service. JIANMENG has own spare parts warehouse, a lot of tool holder can be found in it.Automatic Four Side V Grooving Machine

JM is a leading China automatic four side v grooving machine manufacturer. Grooving machine is highly effective in precision work and corner bending to maintain edges. By using V grooving machine which is stable to bend metal sheets, they can be folded into tight, seamless workpieces.Four Side CNC V Grooving Machine

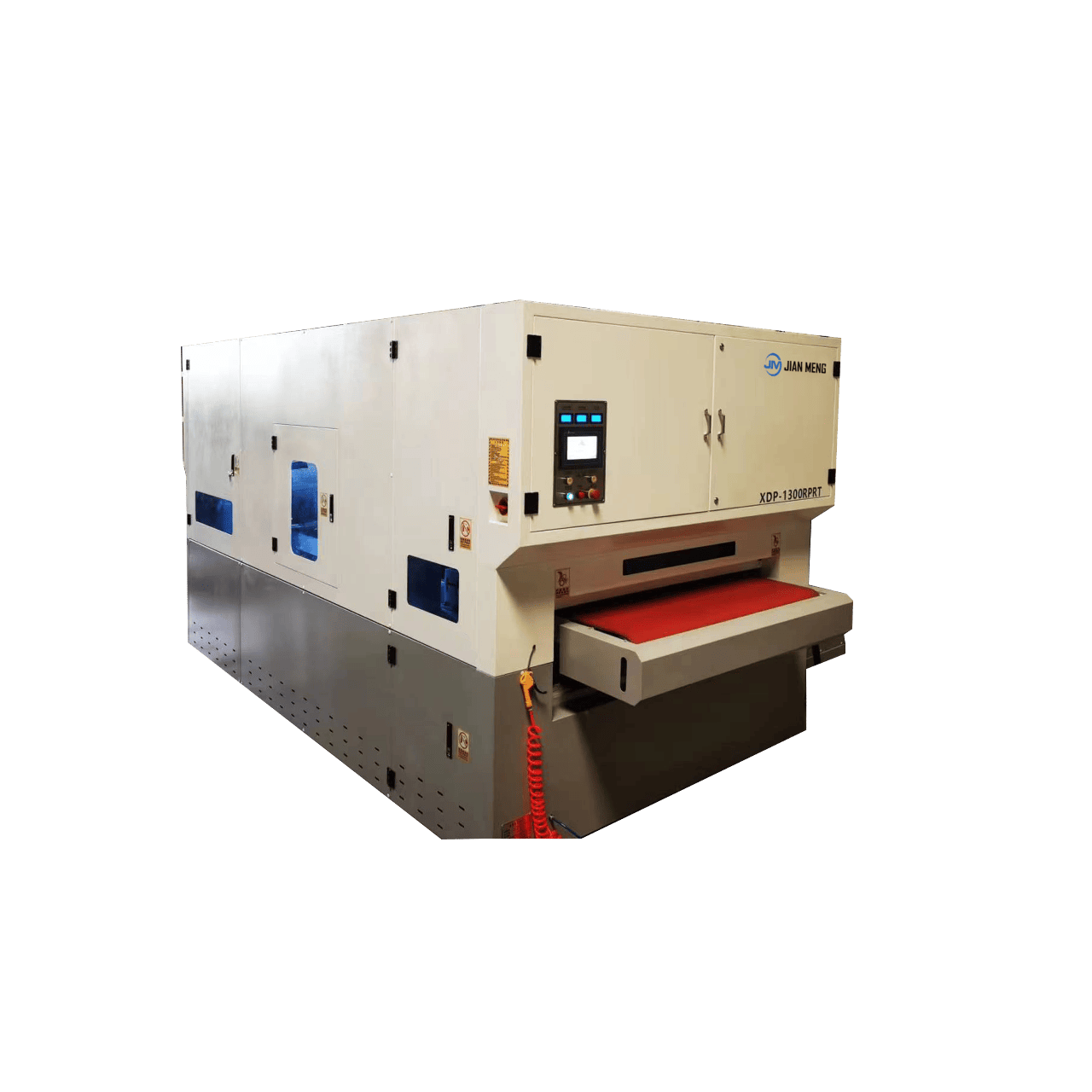

JM is a leading China Four Side CNC V Grooving Machine manufacturer. A metal sheet v grooving machine can create V-shaped grooves in stainless steel sheets, aluminum sheets, composite aluminum sheets, copper sheets, and other metal plates. Four side v grooving machine realize the horizontal grooving of the plate. This allows the bent workpieces to have a very small edge radius, meeting the high precision and aesthetic demands of the high-end sheet metal decoration industry. JIANMENG provides various solutions, making metal fabrication easier!Deburring and wire drawing machine

JM is a leading manufacturer specializing in deburring and wire drawing machine. A deburring machine is a piece of equipment used in the metal processing and manufacturing industry, primarily designed to remove burrs, sharp edges, and oxide layers from workpieces, thereby improving product quality and safety. The XDP-800RPR Deburring & Brushing Machine is a highly integrated and intelligent metal surface treatment system, specifically designed for efficient deburring, chamfering, and brushing processes. Independently developed by Jianmeng, the deburring machine ensures stability and processing precision under complex working conditions through dynamic simulation and process optimization. JIANMENG offers various solutions to enhance the efficiency of metal fabrication!Wet Deburring & Brushing Machine

JM Wet Deburring Machine is a specialized solution for removing burrs, slag, oxide layers, and sharp edges from metal sheets and plates. It operates using wide abrasive belts under wet conditions, ensuring clean, uniform surface finishing without producing harmful dust. This machine is ideal for improving surface quality after laser, plasma, or shear cutting. Featuring a dual abrasive belt structure, the metal finishing machine delivers high-speed, consistent material removal across a wide working width. Automatic deburring machine process cools the material during grinding, prevents thermal deformation, and enhances the lifespan of consumables. Its built-in filtration and water circulation system ensures clean operation and easy maintenance. Suitable for stainless steel, aluminum, copper, the deburring equipment for metal sheet is widely used in industries such as kitchenware, electronics, and general metal fabrication. Compared to dry processing, it offers superior surface results, improved workplace safety, and a more environmentally friendly production process.