China V Grooving Cutting Machine Manufacturers, Suppliers, Factory

With our abundant experience and considerate products and services, we have been recognized to be a reputable supplier for a lot of global consumers for V Grooving Cutting Machine,Grooving Machine,V Grooving Machine,Cutting Machine,V Cutting Machine, We have been wanting forwards to creating long-term company interactions with around the world shoppers.

V Grooving Cutting Machine, In the increasingly competitive market, With sincere service high quality products and well-deserved reputation, we always supply customers support on solutions and techniques to achieve long-term cooperation. Living by quality, development by credit is our eternal pursuit, We firmly believe that after your visit we will become long-term partners.

Hot Products

CNC Horizontal High Speed V Grooving Machine

The CNC Horizontal High Speed V Grooving Machine is a stable V grooving equipment produced by JM, the Chinese manufacturer with the most types of V grooving machines. The CNC horizontal high speed V grooving machines is the most cost-effective grooving machine at medium to low utilization rates.Horizontal High Speed V Cutting Machine For Metal Plates

The Chinese manufacturer JM produces the horizontal high speed V cutting machine for metal plates, it is applicable to all metal plates, such as stainless steel plates, copper plates, galvanized plates and so on.CNC Horizontal Double Drive V Groove Cutting Machine

The Chinese V grooving machine manufacturer JM has been focus on CNC Horizontal Double Drive V Groove Cutting Machine for many years. Its CNC horizontal double drive V groove cutting machine is effective and competitive in market.The CNC horizontal double drive V groove machine from Chinese manufacturer Jianmeng is equipped with intelligent system, easy to master and operate.Vertical High Speed V Grooving Machine For Metal Plates

The Chinese Vertical High Speed V Grooving Machine For Metal Plates manufacturer JM is a comprehensive enterprise that integrates the research and development, production, sales and after-sales of CNC v grooving equipment. The vertical high speed V grooving machine for metal plates from it has a long service life.Vertical High Speed V Slotting Machine For Stainless Steel Plates

JM As the professional Chinese Vertical High Speed V Slotting Machine For Stainless Steel Plates manufacturer, its core advantage is technological innovation. The vertical high speed V slotting machine for stainless steel plates from it has all the advantages of traditional cutting machine and combines with the latest international cutting machine technology, which meets the actual needs of domestic customers.Wet Metal Deburring & Brushing & Polishing Machine

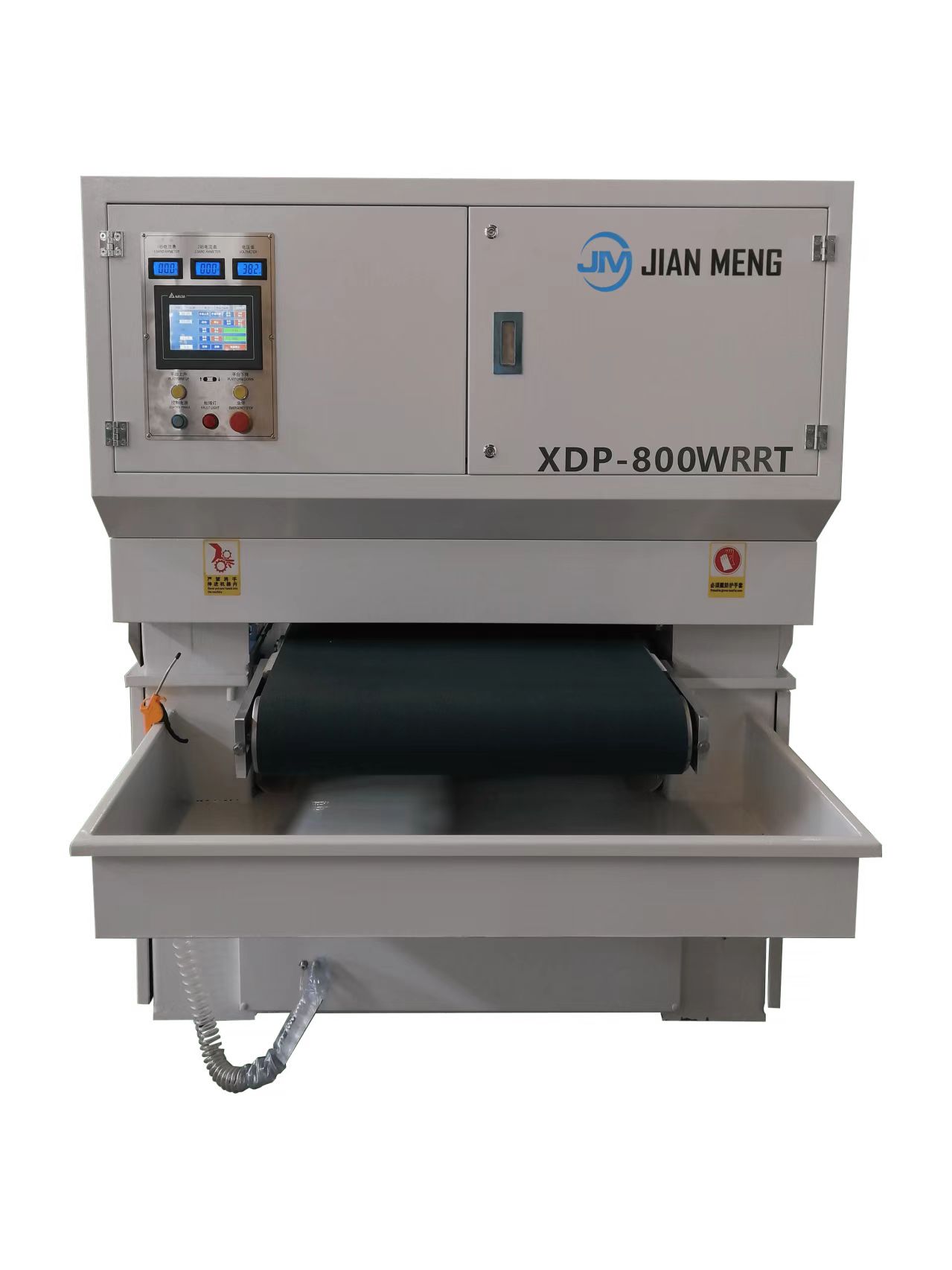

JM Wet Deburring Machine is a high-performance solution designed to efficiently remove burrs, slag, oxide layers, and sharp edges from metal sheets and plates. Utilizing wide abrasive belts in a wet processing environment, it delivers smooth, consistent surface finishes while eliminating harmful dust emissions. This makes it especially effective for post-processing after laser cutting, plasma cutting, or shearing. Equipped with a dual abrasive belt system, the machine ensures fast and uniform material removal across large surfaces. The wet grinding process not only cools the metal during operation—preventing heat-related distortion—but also extends the life of consumables. Its integrated filtration and water recirculation system supports clean, low-maintenance operation. Engineered for materials like stainless steel, aluminum, and copper, this sheet metal deburring machine is widely used in sectors including kitchen appliance manufacturing, electronics, and general metalworking. Compared to dry processing methods, it provides better surface quality, enhances workplace safety, and promotes environmentally responsible manufacturing.