China V Groove Panel Bender Manufacturers, Suppliers, Factory

No matter new customer or old customer, We believe in long term and trusted relationship for V Groove Panel Bender,V Slotting Machine,V Slotting Grooving Machine,V Groove Notching Machine,V Groove Slotting Machine, Prospects first! Whatever you require, we should do our utmost to help you. We warmly welcome clients from all around the globe to cooperate with us for mutual enhancement.

V Groove Panel Bender, Now we have sufficient experience in producing solutions according to samples or drawings. We warmly welcome customers from home and abroad to visit our company, and to cooperate with us for a splendid future together.

Hot Products

CNC Horizontal Double Drive V Grooving Machine

As the professional manufacturer of V grooving machine in China, JM has the most types of V grooving machines, its CNC horizontal double drive V grooving machine makes the processing of dissimilar work is convenient.Four Side V Grooving Machine

A metal sheet v grooving machine can create V-shaped grooves in stainless steel sheets, aluminum sheets, composite aluminum sheets, copper sheets, and other metal plates. Four side v grooving machine realize the horizontal grooving of the plate. This allows the bent workpieces to have a very small edge radius, meeting the high precision and aesthetic demands of the high-end sheet metal decoration industry.Vertical CNC V Groove Machine for Metal Sheet

JM is a leading China vertical cnc v groove machine for metal sheet manufacturer. A metal sheet v grooving machine can create V-shaped grooves in stainless steel sheets, aluminum sheets, composite aluminum sheets, copper sheets, and other metal plates. Vertical v cut machine allows the bent workpieces to have a very small edge radius, meeting the high precision and aesthetic demands of the high-end sheet metal decoration industry. JIANMENG provides various solutions, making metal fabrication easier!Vertical Laser & V Cutting Machine for Sheet Metal

JIANMENG Laser Cutting Machine integrates high-precision laser cutting, intelligent V-grooving, and fully automated production into one system, enabling one-stop processing from flat sheet to finished workpiece. V Grooving & Laser Integrated Machine achieves positioning accuracy of up to ±0.1 mm, delivering smooth, burr-free, deformation-free edges, and is capable of machining complex irregular shapes and sharp, reflection-free bends. Vertical Laser & V Cutting Machine intelligent control system connects directly to engineering drawings, automatically completing cutting path planning, process parameter matching, and continuous whole-sheet processing. Compared with traditional multi-machine, step-by-step workflows,V Grooving & Laser Integrated Machine boosts efficiency by more than three times, reduces process changeover time by over 80%, and ensures top-tier standards in dimensional accuracy, surface quality, and design complexity—making it the ideal choice for high-end architectural decoration and artistic installations.Deburring Polishing & Brushing & Chamfering Machine

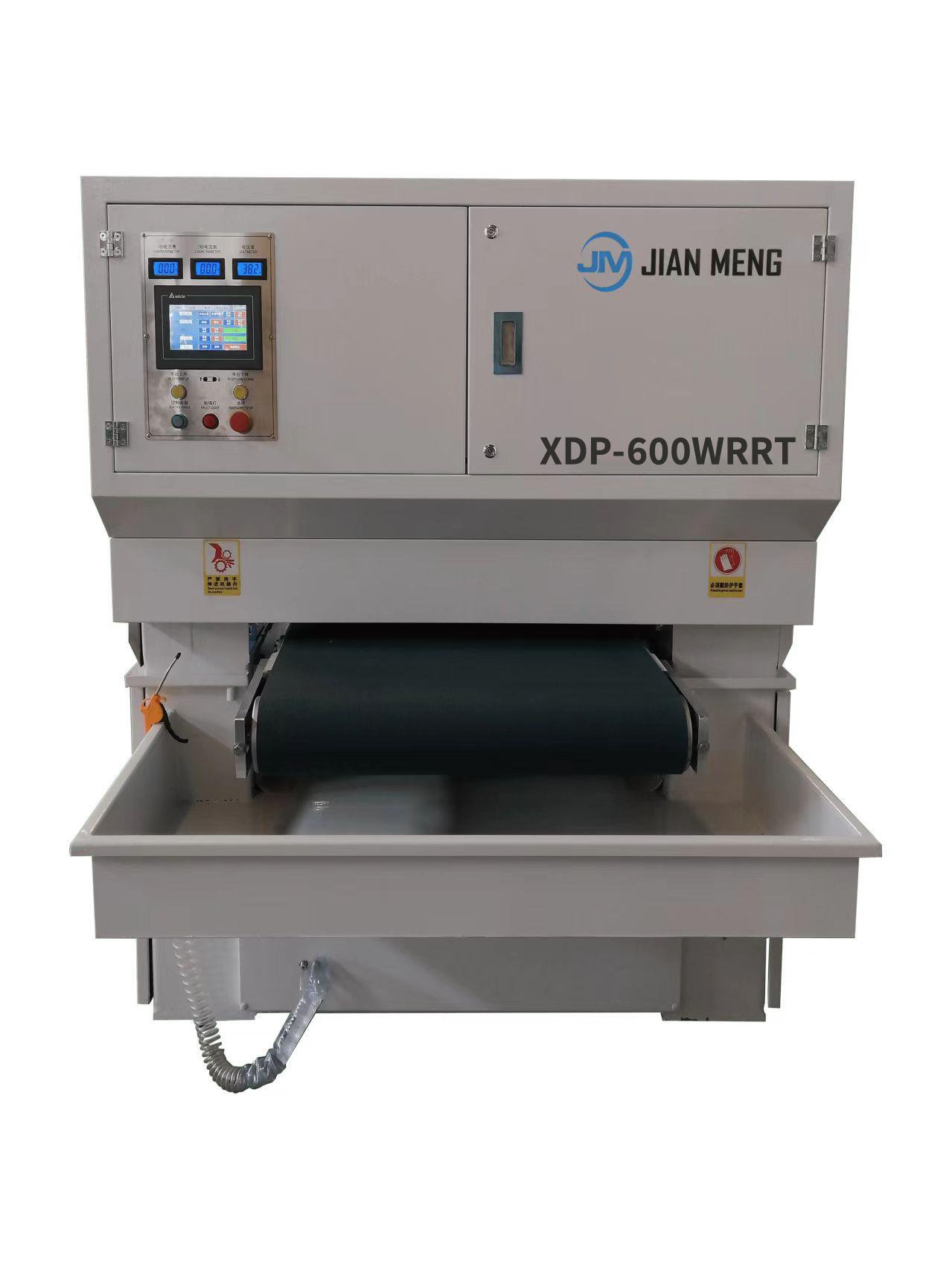

JM Deburring & Brushing Machine stands at the forefront of metal surface treatment technology, specializing in the development of advanced Deburring, Polishing & Brushing Machines. Our solutions combine multiple processes—deburring, polishing, oxide removal, chamfering, and surface brushing—into one streamlined operation. Designed for industries such as sheet metal fabrication, automotive components, and precision instruments, Metal Finishing Machine delivers exceptional results across materials including stainless steel, carbon steel, aluminum, and copper. It removes burrs, sharp edges, and surface imperfections with ease, ensuring clean, safe, and consistent finishes. With a focus on efficiency, reliability, and intelligent control, Metal Finishing Machine help manufacturers enhance both product quality and throughput. By integrating superior performance with user-friendly operation, we provide a complete surface finishing solution that drives productivity and consistency. For companies seeking to raise their standards in metalworking, Deburring & Brushing Machine offers the trusted choice in achieving flawless surface quality and optimized production efficiency.CNC Deburring, Brushing & Polishing Machine for metal sheet

JM is a premier manufacturer committed to delivering cutting-edge solutions in metal surface finishing. Our advanced deburring, polishing, and brushing systems combine efficiency, precision, and intelligence—integrating deburring, polishing, oxide removal, chamfering, and surface brushing into a single, seamless process. Designed for the demanding needs of sheet metal fabrication, automotive components, and precision instrument industries, JM’s Industrial Deburring Machines ensure perfectly smooth, safe edges on stainless steel, carbon steel, aluminum, and copper. With outstanding performance in efficiency, stability, and smart control, our automatic systems help manufacturers enhance product quality, maintain consistency, and accelerate production—offering a dependable, all-in-one solution for superior surface treatment. For enterprises pursuing excellence in metal processing, JM’s technology stands as the trusted choice for achieving flawless results.