China power hammer Manufacturers, Suppliers, Factory

We are commitment to offer the competitive price ,outstanding products quality, as well as fast delivery for power hammer,kraftformer,Metal Forming Machine,Shrinking Machine,Metal Stretching Machine, On account of superior top quality and aggressive selling price , we'll be the market leader, be sure to don’t wait to get in touch with us by phone or email, should you be intrigued in almost any of our products.

power hammer, With the spirit of "credit first, development through innovation, sincere cooperation and joint growth", our company is striving to create a brilliant future with you, so as to become a most valuable platform for exporting our products in China!

Hot Products

Horizontal High Speed V Slotting Machine For Stainless Steel Plates

The V grooving machine manufacturer JM in China provides the most types of of Horizontal High Speed V Slotting Machine For Stainless Steel Plates, this machine also can be used for processing other metals plates, such as aluminium plates, galvanized plates and so on.CNC Horizontal Double Drive V Grooving Machine For Stainless Steel Plates

As the famous V grooving machine manufacturer in China, JM provide customers with professional equipment and assistance, the CNC Horizontal Double Drive V Grooving Machine For Stainless Steel Plates is easy to operate.Horizontal V Grooving Machine

JM is a professional leader China Horizontal V Grooving Machine manufacturer with high quality and reasonable price. A metal sheet v grooving machine can create V-shaped grooves in stainless steel sheets, aluminum sheets, composite aluminum sheets, copper sheets, and other metal plates. This allows the bent workpieces to have a very small edge radius, meeting the high precision and aesthetic demands of the high-end sheet metal decoration industry.JIANMENG provides various solutions, making metal fabrication easier!Deburring and wire drawing machine

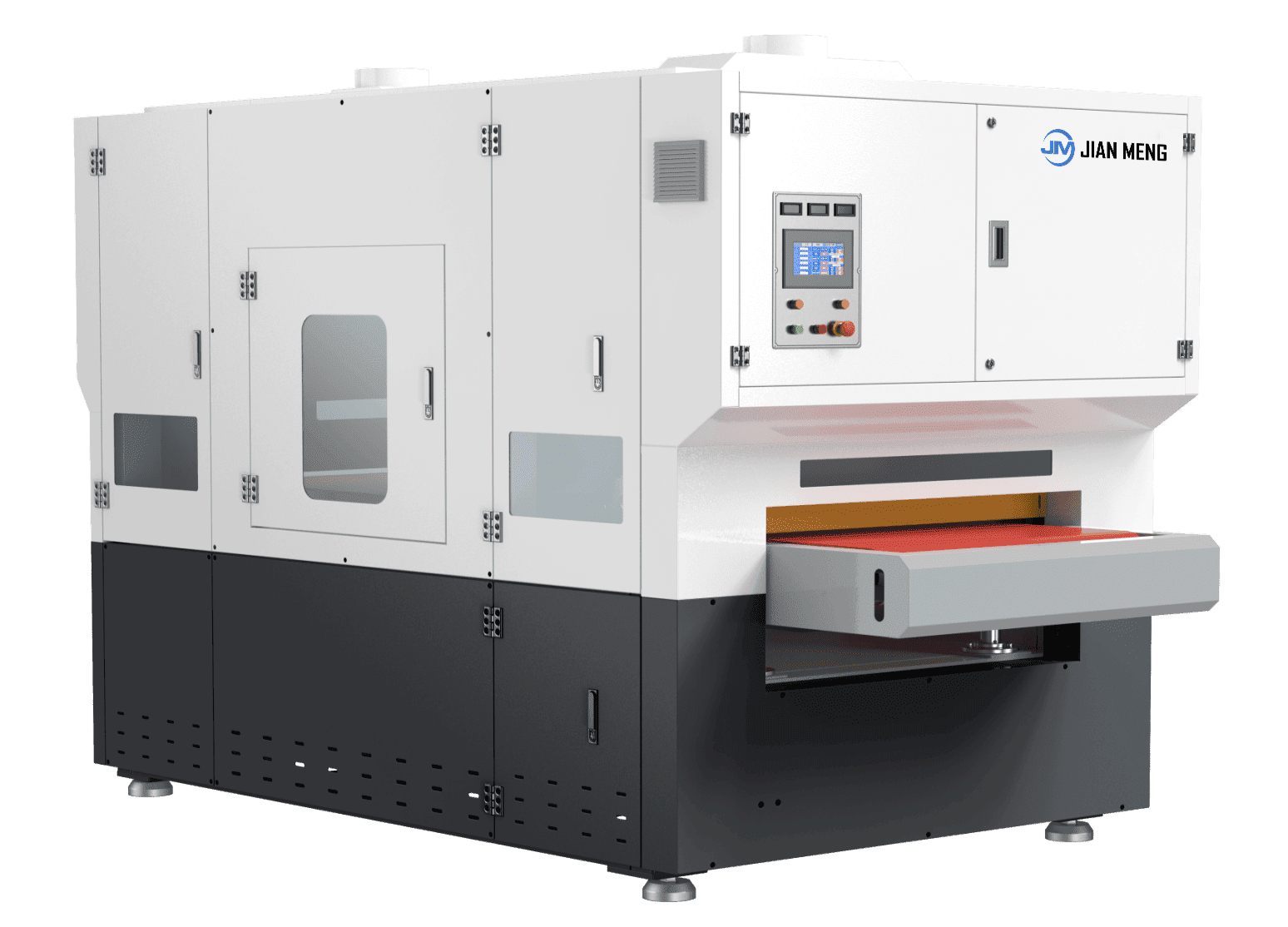

JM is a leading manufacturer specializing in deburring and wire drawing machine. A deburring machine is a piece of equipment used in the metal processing and manufacturing industry, primarily designed to remove burrs, sharp edges, and oxide layers from workpieces, thereby improving product quality and safety. The XDP-800RPR Deburring & Brushing Machine is a highly integrated and intelligent metal surface treatment system, specifically designed for efficient deburring, chamfering, and brushing processes. Independently developed by Jianmeng, the deburring machine ensures stability and processing precision under complex working conditions through dynamic simulation and process optimization. JIANMENG offers various solutions to enhance the efficiency of metal fabrication!Pneumatic Metal Forming Machine

JIANMENG specializes in advanced Metal Shaping Machine, engineered for high-precision, chip-free processing of metal sheets with exceptionally low noise. These Metal shrinker machine support a wide range of metal forming applications, making them an ideal solution for both manufacturing new components and performing precise adjustments or repairs on existing parts. With rapid tool change capabilities and smooth transitions between functions, JIANMENG solutions are designed to maximize flexibility and efficiency. The PMF 400Metal Shaping Machine stands out with its reinforced structure and significantly increased forming pressure, enabling it to handle more demanding tasks. Its modular die system supports a variety of easily interchangeable tools—including shrinker and stretcher toolings—offering unmatched adaptability in metal forming operations. Built for long service life, high precision, and multifunctionality, JIANMENG delivers next-generation forming technology that sets a new standard for efficiency, control, and performance in modern metal fabrication.CNC Carbon Steel Deburring &Brushing& Edge roundingBrushing Machine

The deburring and chamfering machine is specifically designed for surface treatment of carbon steel components. Automatic Deburring Machine features an innovative combination of three sets of wide abrasive belts and six universal rotary brushes for chamfering. This design ensures efficient and precise removal of surface burrs while achieving edge chamfering and surface brushing, significantly improving the surface quality and appearance of the workpiece. The Deburring & Brushing&edge rounding Machine meets the precision and quality requirements of carbon steel surface treatment across various industries, enhancing both production efficiency and product value. Parameters can be adjusted according to different processing needs, and suitable abrasives can be selected accordingly. The metal deburring machine is equipped with one 5.5kW wet dust collector. Dust removal method: The dust generated during operation is effectively extracted through a dust collection port, eliminating most of the dust, preventing potential dust explosion hazards, and keeping the internal structure clean.