- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China CNC V Groove Slotting Equipment Manufacturers, Suppliers, Factory

To be able to ideal meet up with client's needs, all of our operations are strictly performed in line with our motto "High High-quality, Competitive Cost, Fast Service" for CNC V Groove Slotting Equipment,CNC Sheet Metal V Groove Machine,V Groove Shearing Machine,V Groove Forming Machine,V Groove Bending and Punching Machine, We play a leading role in giving buyers with high-quality goods fantastic provider and competitive selling prices.

CNC V Groove Slotting Equipment, You can do one-stop shopping here. And customized orders are acceptable. Real business is to get win-win situation, if possible, we would like to deliver more support for customers. Welcome all nice buyers communicate details of solutions and ideas with us!!

Hot Products

CNC Horizontal High Speed V Grooving Machine

The CNC Horizontal High Speed V Grooving Machine is a stable V grooving equipment produced by JM, the Chinese manufacturer with the most types of V grooving machines. The CNC horizontal high speed V grooving machines is the most cost-effective grooving machine at medium to low utilization rates.Vertical High Speed V Groove Cutting Machine

The V grooving machine manufacturer JM in China is professional and durable, its vertical high speed V groove cutting machine is the best choice, when there is a need to process the mirror plate.Vertical High Speed V Groove Slotting Machine

The Vertical High Speed V Groove Slotting Machine manufacturer JM in China has a standard rack production workshop, with technological innovation as its core advantage. Its vertical high speed V grooving machine make use in processing mirror plates.Automatic Four Side V Groove Cutting Machine

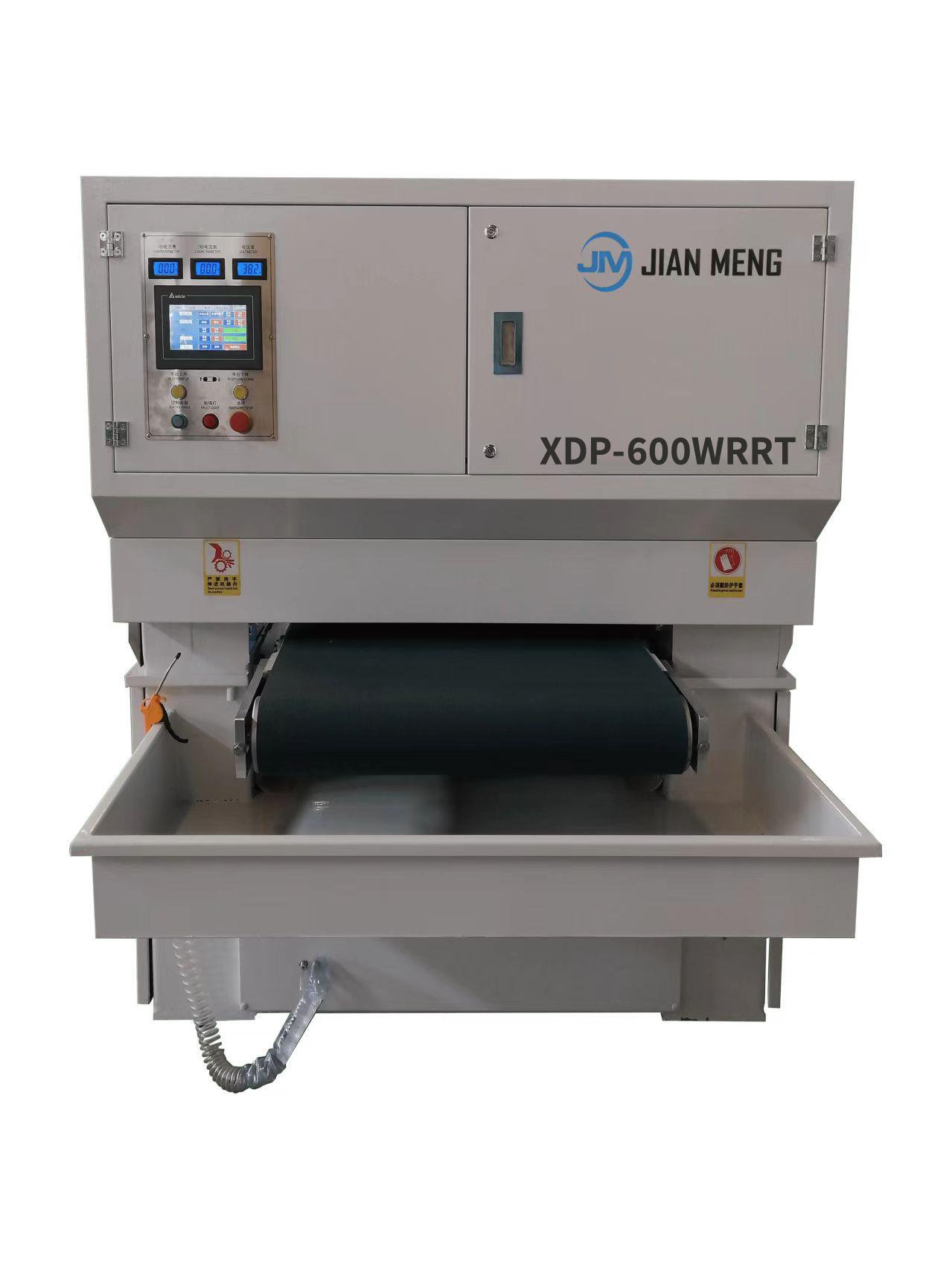

JM is the professional China manufacturer and supplier of automatic four side V groove cutting machine with affordable price. If customers choose to use automatic four side V groove cutting machine, the workpiece no longer needs to be shifted manually, which greatly improves the dimensional accuracy, saves labor costs, saves time costs and improves production efficiency.CNC Wet Metal Deburring & Brushing & Polishing Machine

JM Wet Deburring Machine is a high-performance solution designed to efficiently remove burrs, slag, oxide layers, and sharp edges from metal sheets and plates. Utilizing wide abrasive belts in a wet processing environment, it delivers smooth, consistent surface finishes while eliminating harmful dust emissions. This makes it especially effective for post-processing after laser cutting, plasma cutting, or shearing. Equipped with a dual abrasive belt system, the machine ensures fast and uniform material removal across large surfaces. The wet grinding process not only cools the metal during operation—preventing heat-related distortion—but also extends the life of consumables. Its integrated filtration and water recirculation system supports clean, low-maintenance operation. Engineered for materials like stainless steel, aluminum, and copper, this sheet metal deburring machine is widely used in sectors including kitchen appliance manufacturing, electronics, and general metalworking. Compared to dry processing methods, it provides better surface quality, enhances workplace safety, and promotes environmentally responsible manufacturing.Electro-Hydraulic Synchronous CNC Bending Machine

The Press Brake is a sophisticated and intelligent sheet metal forming system designed to meet diverse fabrication needs. Its structural framework, developed by JIANMENG Smart, utilizes PRO/E 3D modeling and finite element analysis (FEA) to ensure optimal frame strength and rigidity according to international standards. Made from premium Q235B steel, the frame is treated with shot blasting, anti-corrosion coating, and vibration stress-relief processes to improve mechanical stability, durability, and long-term reliability.