- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China V Groove Bending and Punching Machine Manufacturers, Suppliers, Factory

We've one of the most advanced generation tools, experienced and qualified engineers and workers, recognized good quality manage systems and a friendly skilled product sales workforce pre/after-sales support for V Groove Bending and Punching Machine,CNC Sheet Metal V Groove Machine,V Groove Shearing Machine,V Groove Forming Machine,V Groove Plate Cutting Machine, We warmly welcome clients from all around the world for almost any sort of cooperation with us to build a mutual advantage potential. We've been devoting ourselves wholeheartedly to supply consumers the very best company.

V Groove Bending and Punching Machine, All of our solutions comply with international quality standards and are greatly appreciated in a variety of markets around the world. If you are interested in any of our products or would like to discuss a custom order, be sure to feel free to contact us. We've been looking forward to forming successful business relationships with new clients in the near future.

Hot Products

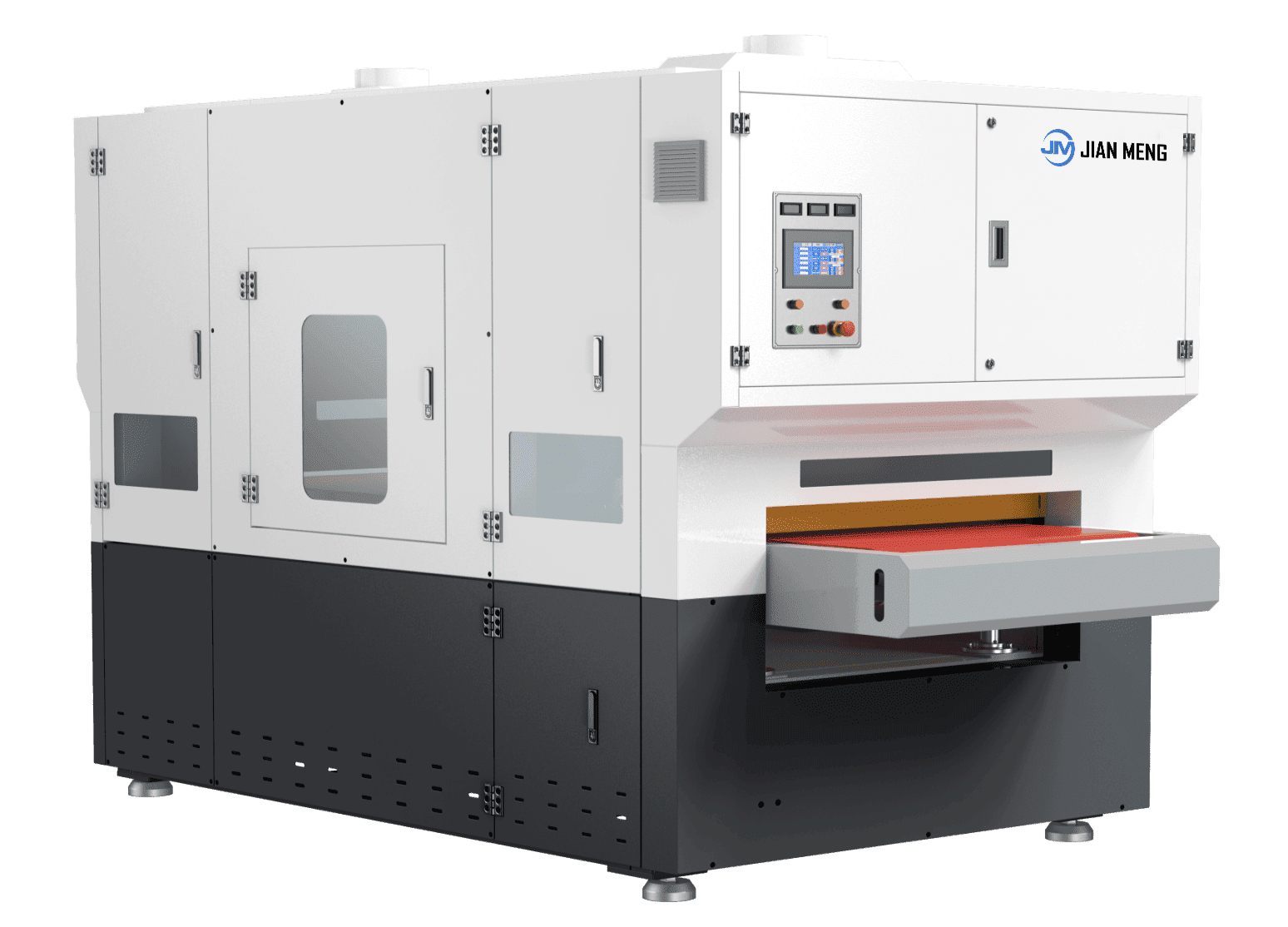

CNC Horizontal High Speed V Groove Slotting Machine

The Chinese manufacturer JM has the most types of V grooving machines in China, the CNC horizontal high speed v groove slotting machine from it is a professional and cost-effectiveness V grooving equipment.Horizontal Double Drive V Slotting Machine For Stainless Steel Plate

The professional V grooving machine manufacturer JM in China not only has excellent horizontal double drive V slotting machine for stainless steel plate, but also provide considerate after-sales service. The groove processed by horizontal double drive V slotting machine for stainless steel plate is as smooth as a mirror.Vertical Back And Forth Cutting Machine

The V cutting machine manufacturer JM in China produces the excellent vertical back and forth cutting machine. The vertical back and forth cutting machine combines with all characteristics of traditional models.Automatic Four Side V-shaped Grooving Machine

JM as a professional automatic four side v-shaped grooving machine manufacturer in China, it offers high energy efficiency automatic four side V -shaped grooving machine. This machine can play an important role in rigid boxes processing.Wet Metal Deburring & Brushing & Polishing Machine

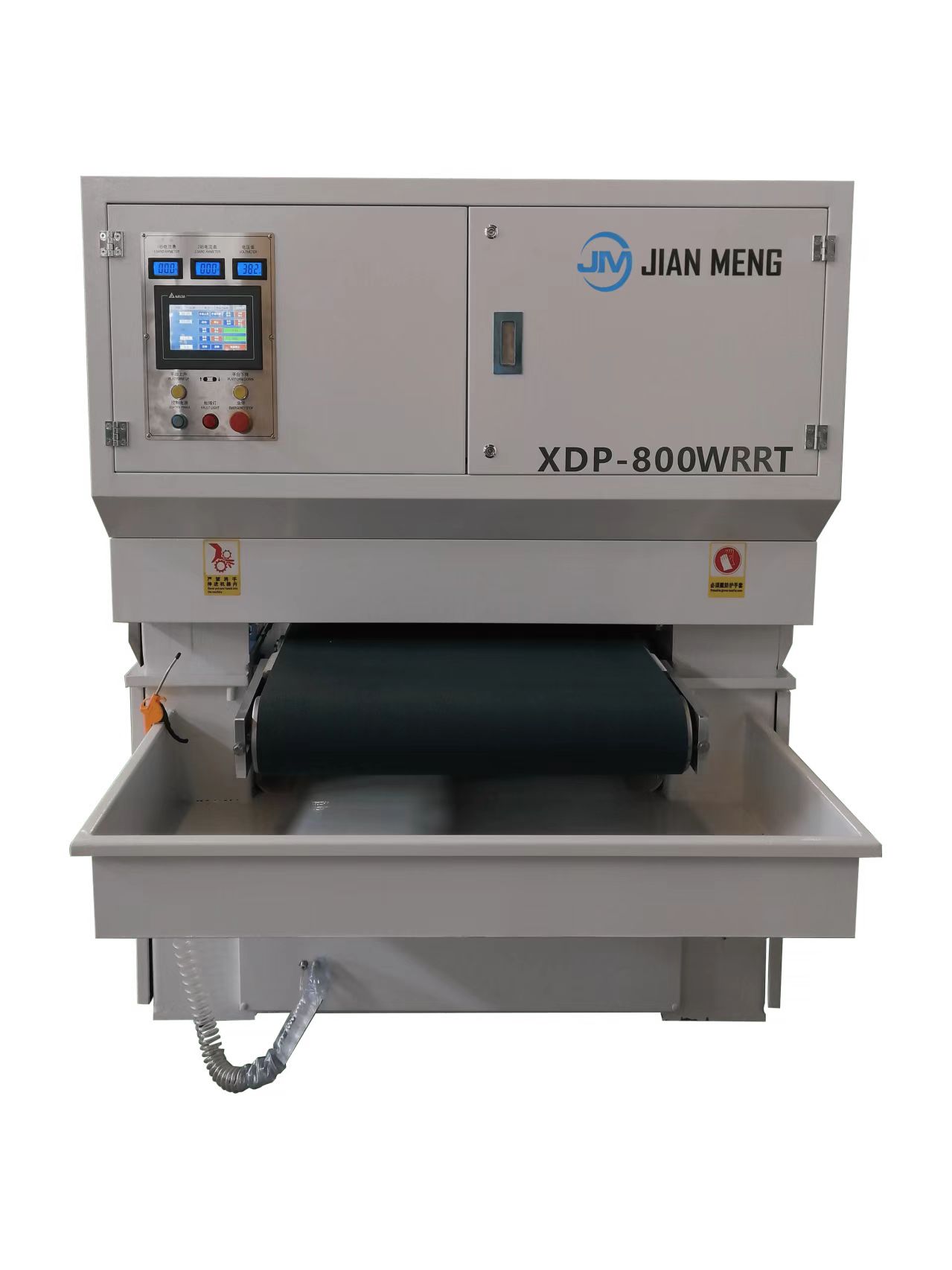

JM Wet Deburring Machine is a high-performance solution designed to efficiently remove burrs, slag, oxide layers, and sharp edges from metal sheets and plates. Utilizing wide abrasive belts in a wet processing environment, it delivers smooth, consistent surface finishes while eliminating harmful dust emissions. This makes it especially effective for post-processing after laser cutting, plasma cutting, or shearing. Equipped with a dual abrasive belt system, the machine ensures fast and uniform material removal across large surfaces. The wet grinding process not only cools the metal during operation—preventing heat-related distortion—but also extends the life of consumables. Its integrated filtration and water recirculation system supports clean, low-maintenance operation. Engineered for materials like stainless steel, aluminum, and copper, this sheet metal deburring machine is widely used in sectors including kitchen appliance manufacturing, electronics, and general metalworking. Compared to dry processing methods, it provides better surface quality, enhances workplace safety, and promotes environmentally responsible manufacturing.Automatic Thin Sheet Deburring Machine

JM is a leading manufacturer dedicated to advanced thin sheet deburring solutions. Our deburring machine is designed to efficiently remove burrs and perform chamfering on a wide range of metal workpieces, ensuring superior surface quality. By integrating abrasive belt deburring with roller brush chamfering, the machine enables multiple surface finishing processes in a single pass, significantly boosting both production efficiency and product consistency. Automatic Deburring Machine is compatible with materials such as stainless steel, aluminum alloys, steel plates, and copper plates. Operators can easily adjust processing parameters and select the most suitable abrasives according to specific requirements. With its high efficiency, operational stability, and intelligent control features, the JM Thin Sheet Deburring Machine offers metalworking enterprises a truly one-stop surface treatment solution. From enhancing product quality to streamlining production, it is an indispensable asset for modern manufacturing.