China V Groove Cutting and Bending Machine Manufacturers, Suppliers, Factory

All we do is usually affiliated with our tenet " Buyer to start with, Belief to start with, devoting about the food packaging and environmental defense for V Groove Cutting and Bending Machine,Grooving Machine,V Grooving Machine,Cutting Machine,V Cutting Machine, sincerity and strength ,constantly preserve approved superior quanlity ,welcome to our factoty for pay a visit to and instruction and organization.

V Groove Cutting and Bending Machine, We've got constantly insisted on the evolution of solutions, spent good funds and human resource in technological upgrading, and facilitate production improvement, meeting the wants of prospects from all countries and regions.

Hot Products

Horizontal Double Drive V Slotting Machine

As the professional V grooving machine manufacturer in China, JM produces the cost-effective horizontal double drive V slotting machine for processing metal plates, this machine is easy to master and operate.Horizontal Double Drive V Grooving Machine For Metal Plates

The Chinese metal plate processing machine manufacturer JM produces ultra-precision Horizontal Double Drive V Grooving Machine For Metal Plates, supply 100% technical independent maintenance services and perfect logistics support.CNC Vertical High Speed V Slotting Machine For Stainless Steel Plates

The V grooving machine manufacturer JM in China provides the professional CNC vertical high speed V slotting machine for stainless steel plates with high energy efficiency and low maintenance, it can significantly improve production energy efficiency and slot speed.Vertical High Speed V Cutting Machine For Stainless Steel Plates

The manufacturer JM in China is one of professional manufacturer and exporter of Vertical High Speed V Cutting Machine For Stainless Steel Plates. The vertical high speed V cutting machine for stainless steel plates is an upgraded product of traditional grooving machine.Wet Deburring & Brushing Machine

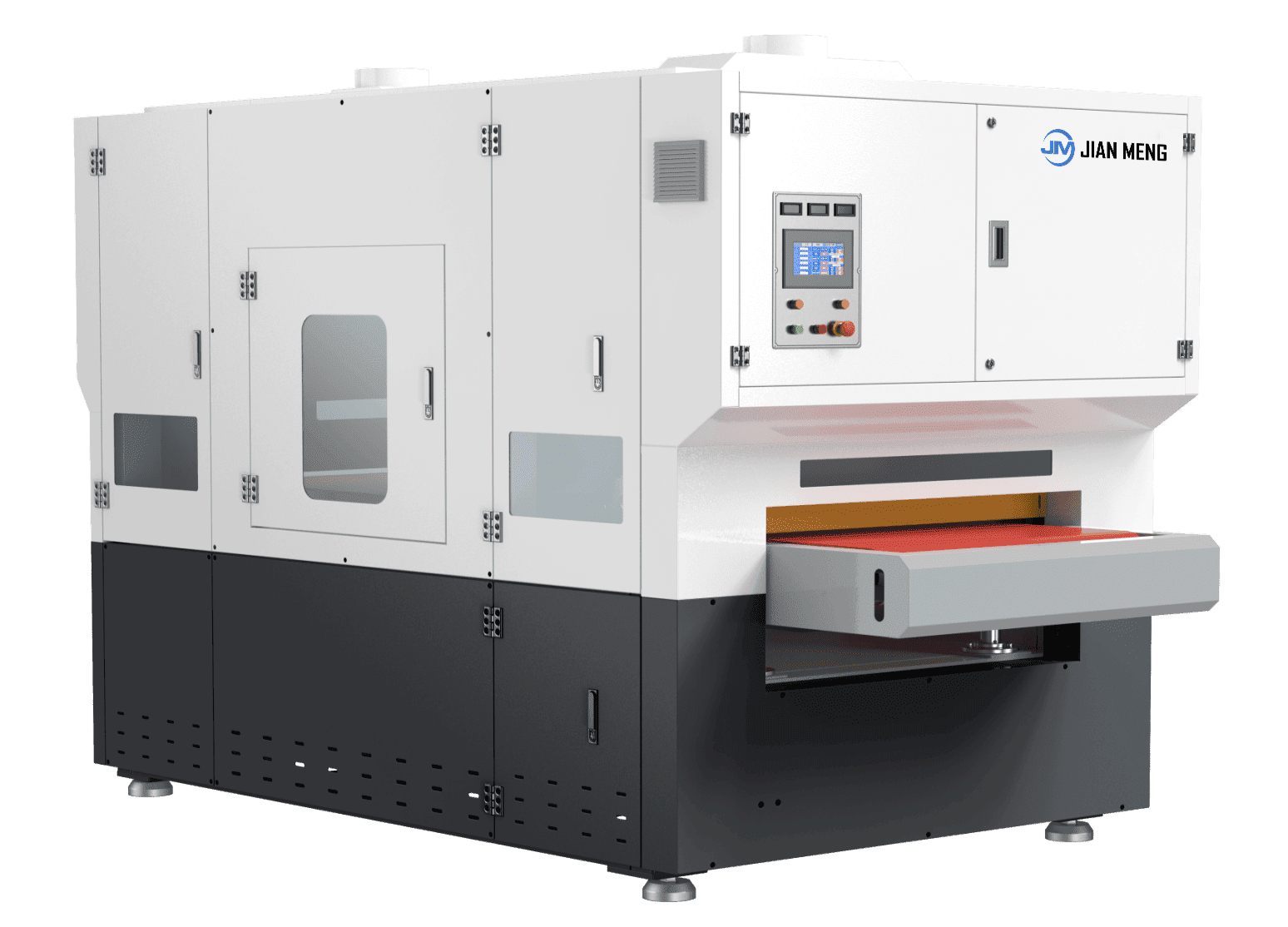

JM Wet Deburring Machine is a specialized solution for removing burrs, slag, oxide layers, and sharp edges from metal sheets and plates. It operates using wide abrasive belts under wet conditions, ensuring clean, uniform surface finishing without producing harmful dust. This machine is ideal for improving surface quality after laser, plasma, or shear cutting. Featuring a dual abrasive belt structure, the metal finishing machine delivers high-speed, consistent material removal across a wide working width. Automatic deburring machine process cools the material during grinding, prevents thermal deformation, and enhances the lifespan of consumables. Its built-in filtration and water circulation system ensures clean operation and easy maintenance. Suitable for stainless steel, aluminum, copper, the deburring equipment for metal sheet is widely used in industries such as kitchenware, electronics, and general metal fabrication. Compared to dry processing, it offers superior surface results, improved workplace safety, and a more environmentally friendly production process.CNC Carbon Steel Deburring &Brushing& Edge roundingBrushing Machine

The deburring and chamfering machine is specifically designed for surface treatment of carbon steel components. Automatic Deburring Machine features an innovative combination of three sets of wide abrasive belts and six universal rotary brushes for chamfering. This design ensures efficient and precise removal of surface burrs while achieving edge chamfering and surface brushing, significantly improving the surface quality and appearance of the workpiece. The Deburring & Brushing&edge rounding Machine meets the precision and quality requirements of carbon steel surface treatment across various industries, enhancing both production efficiency and product value. Parameters can be adjusted according to different processing needs, and suitable abrasives can be selected accordingly. The metal deburring machine is equipped with one 5.5kW wet dust collector. Dust removal method: The dust generated during operation is effectively extracted through a dust collection port, eliminating most of the dust, preventing potential dust explosion hazards, and keeping the internal structure clean.