- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Horizontal V Grooving Machine

- Vertical V Grooving Machine

- Automatic Four Side V Grooving Machine

- V Grooving Machine Accessory

- Metal Forming Machine

- Deburring Machine

- Thin Sheet Deburring Machine

- Abrasive Belt Deburring Machine

- Carbon Steel Deburring Machine

- Deburring and Brushing Machine

- Manual Deburring Machine

- Wet Dust Collector

- Deburring Polishing & Brushing Machine

- Deburring & Chamfering Machine

- Wet Deburring & Brushing Machine

- Deburring, Edge rounding & Polishing Machine

- Carbon Steel Deburring & Brushing & Edge rounding Machine

- Dry Deburring, Brushing, and Polishing Machine

- Deburring and Brushing Machine with Slag Hammer Disc

- Shearing Machine

- Press Brake

Products

- View as

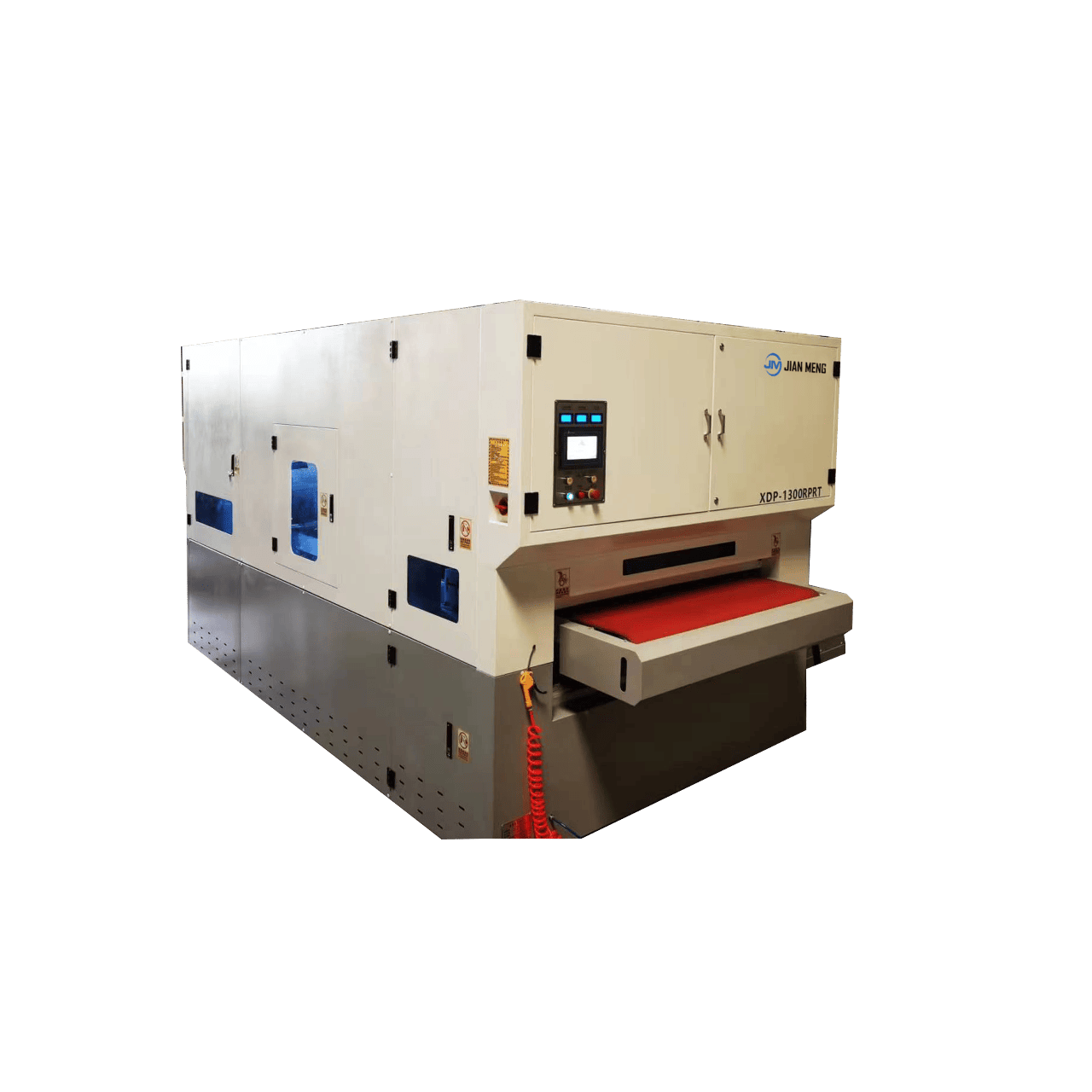

CNC Deburring, Chamfering & Polishing Machine

JM, a trusted manufacturer, has developed the advanced RPT series of deburring, polishing, and brushing machines to meet the highest standards of modern metal finishing. This versatile machine combines abrasive belt deburring, universal roller brush chamfering, and polishing and brushing finishing into a single, efficient process, providing a comprehensive surface treatment solution. The RPT machine is widely used in sheet metal fabrication, automotive parts production, precision instrument manufacturing, and other industries where edge quality and surface finish are critical. It reliably removes burrs, sharp edges, and irregularities from stainless steel, carbon steel, aluminum, copper, and various other metals, resulting in a smooth, secure, and fine finish. Designed for high perfo......

Read MoreSend InquiryAutomatic Thin Sheet Deburring Machine

JM is a leading manufacturer dedicated to advanced thin sheet deburring solutions. Our deburring machine is designed to efficiently remove burrs and perform chamfering on a wide range of metal workpieces, ensuring superior surface quality. By integrating abrasive belt deburring with roller brush chamfering, the machine enables multiple surface finishing processes in a single pass, significantly boosting both production efficiency and product consistency. Automatic Deburring Machine is compatible with materials such as stainless steel, aluminum alloys, steel plates, and copper plates. Operators can easily adjust processing parameters and select the most suitable abrasives according to specific requirements. With its high efficiency, operational stability, and intelligent control features,......

Read MoreSend InquiryCNC Deburring, Edge rounding & Polishing Machine

JM is a leading manufacturer specializing in the production of advanced RPT Deburring, Polishing & Brushing Machines, designed to meet the highest standards of modern metal surface processing. This highly efficient and intelligent equipment integrates abrasive belt deburring, universal roller brush chamfering, and polishing roller brushing into one process, providing an all-in-one solution for surface finishing. The RPT Machine is widely applied in sheet metal fabrication, automotive parts manufacturing, precision instrument production, and other industries that require superior edge and surface quality. It effectively removes burrs, sharp edges, and surface irregularities from stainless steel, carbon steel, aluminum, copper, and other metals, ensuring smooth, safe, and refined surfaces......

Read MoreSend InquiryDeburring Polishing & Brushing Machine for metal sheet

JM is a leading manufacturer dedicated to developing and producing advanced deburring, polishing, and brushing equipment that meets the highest standards of modern metal surface processing. This efficient and intelligent machine integrates deburring, polishing, oxide removal, chamfering, and surface brushing in one process. Widely used in sheet metal fabrication, automotive parts, and precision instruments, the Industrial Deburring Machine effectively removes burrs, sharp edges, and defects from stainless steel, carbon steel, aluminum, and copper, ensuring smooth and safe edges. Designed for high efficiency, stability, and smart operation, Automatic Deburring Machine enhances workpiece quality, improves consistency, and boosts production speed—providing manufacturers with a reliable,......

Read MoreSend InquiryDeburring Polishing & Brushing & Chamfering Machine

JM Deburring & Brushing Machine stands at the forefront of metal surface treatment technology, specializing in the development of advanced Deburring, Polishing & Brushing Machines. Our solutions combine multiple processes—deburring, polishing, oxide removal, chamfering, and surface brushing—into one streamlined operation. Designed for industries such as sheet metal fabrication, automotive components, and precision instruments, Metal Finishing Machine delivers exceptional results across materials including stainless steel, carbon steel, aluminum, and copper. It removes burrs, sharp edges, and surface imperfections with ease, ensuring clean, safe, and consistent finishes. With a focus on efficiency, reliability, and intelligent control, Metal Finishing Machine help manufacturers enhance b......

Read MoreSend InquiryVertical Laser & V Cutting Machine for Sheet Metal

JIANMENG Laser Cutting Machine integrates high-precision laser cutting, intelligent V-grooving, and fully automated production into one system, enabling one-stop processing from flat sheet to finished workpiece. V Grooving & Laser Integrated Machine achieves positioning accuracy of up to ±0.1 mm, delivering smooth, burr-free, deformation-free edges, and is capable of machining complex irregular shapes and sharp, reflection-free bends. Vertical Laser & V Cutting Machine intelligent control system connects directly to engineering drawings, automatically completing cutting path planning, process parameter matching, and continuous whole-sheet processing. Compared with traditional multi-machine, step-by-step workflows,V Grooving & Laser Integrated Machine boosts efficiency by more than three ti......

Read MoreSend Inquiry