- Horizontal V Grooving Machine

- Vertical V Grooving Machine

- Automatic Four Side V Grooving Machine

- V Grooving Machine Accessory

- Metal Forming Machine

- Deburring Machine

- Thin Sheet Deburring Machine

- Abrasive Belt Deburring Machine

- Carbon Steel Deburring Machine

- Deburring and Brushing Machine

- Manual Deburring Machine

- Wet Dust Collector

- Deburring Polishing & Brushing Machine

- Deburring & Chamfering Machine

- Wet Deburring & Brushing Machine

- Deburring, Edge rounding & Polishing Machine

- Carbon Steel Deburring & Brushing & Edge rounding Machine

- Dry Deburring, Brushing, and Polishing Machine

- Deburring and Brushing Machine with Slag Hammer Disc

- Shearing Machine

- Press Brake

CNC Swing Beam Shearing Machine

JM CNC Swing Beam Shearing Machine is a commonly used cutting device in metal processing, which shears metal sheets by swinging the blade. The working principle involves the upper blade holder moving in a swinging motion around a fixed axis, pressing the metal sheet against the lower blade to complete the cutting operation. The swing beam shearing machine is typically used for processing thinner metal sheets and is known for its simple structure, ease of operation, and efficiency. It is widely applied in industries such as machinery manufacturing and sheet metal processing, making it suitable for high-volume production and precise cutting needs. The swing beam shearing machine adopts high technical standards, design, and a user-friendly interface. We have reduced the cutting angle to achieve straight-line precision and minimal distortion tolerance. The JM swing beam shearing machine provides high-standard safety and efficient solutions that can enhance your capabilities and add value to your company.

Model:QC12Y-6×3200

Send Inquiry

Swing Beam Shearing Machine

Perfect Shearing: The QC12Y-6×3200 Guillotine CNC Swing Beam Shearing Machine achieves perfect cutting, efficiently and precisely processing various metal sheets to ensure smooth, burr-free edges with every cut. With advanced technology and high-precision control systems, it is widely used in industries such as machinery manufacturing, sheet metal processing, and automotive production for fine cutting of materials like steel plates, stainless steel, and aluminum sheets, meeting high-standard processing requirements.

Main configuration list

Control System:Nanjing Estun (E21S)

Internal Gear Pump:USA Sunny

Main Motor:China Shenghui Motor

Sealing Components:USA Parker

Main Electrical Components:France Schneider

Blade:China SJ

Ball Screw:China Enze

E21S control system

The Estun E21S control system is a specialized CNC device designed for Swing Beam Shearing Machine , suitable for a wide range of users. It significantly reduces the cost of CNC shearing machine while ensuring high work precision.

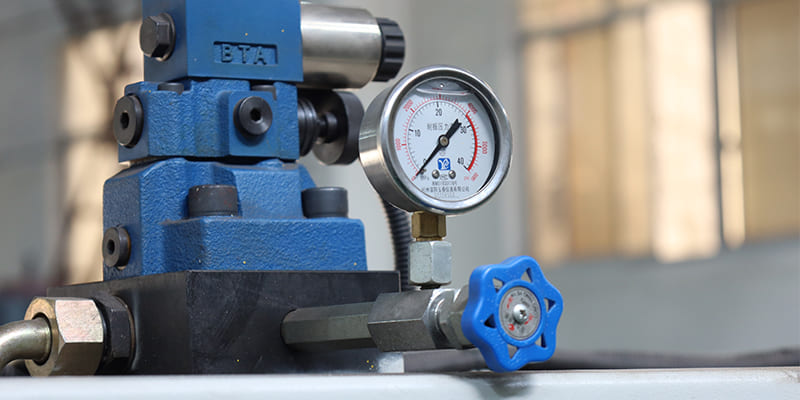

Durable Hydraulic Pressure Gauge

The durable hydraulic pressure gauge on a swing beam shearing machine is a key component used to monitor the working pressure of the hydraulic system in real time. It is typically installed in the main circuit of the hydraulic system. This gauge accurately reflects changes in hydraulic load during the shearing process, assisting operators in assessing the machine's operating condition and ensuring the stability and safety of cutting operations. In the event of abnormal system pressure, the gauge readings serve as a vital reference for fault diagnosis, prompting timely maintenance or adjustments. High-quality endurance pressure gauges are usually designed with shock-resistant and leak-proof features, offering clear readings and strong impact resistance, making them ideal for precise monitoring under long-term, high-frequency shearing conditions.

Spring Pressure Cylinder

The Spring Pressure Cylinder of a Swing Beam Shearing Machine is a component used to assist in stabilizing and supporting the material, especially during the cutting process. The role of the Spring Pressure Cylinder is to ensure that the material is firmly pressed and held in place during cutting, preventing displacement or warping, thereby improving cutting accuracy and safety.

QC11Y-6×2500 Guillotine Shearing Machine

Maximum Shearable Plate Thickness ( Mild Steel )

6.0mm

Maximum Shearable Plate Thickness ( Stainless Steel )

3.0mm

Plate Tensile Strength for Shearing

450-650 N/mm2

Maximum Shearable Plate Width

3200 mm

Working Table Height

800 mm

Backgauge Stroke

10-600 mm

Application Fields

The swing beam shearing machine is widely used across various industrial sectors, particularly in sheet metal processing, machinery manufacturing, automotive parts, shipbuilding, electrical equipment, home appliances, and architectural decoration. It is primarily employed for high-efficiency, high-precision straight-line cutting of various metal sheets, including carbon steel, stainless steel, aluminum plates, and galvanized sheets. With its simple structure, easy operation, and stable cutting quality, the swing beam shearing machine has become an essential piece of equipment for processing medium and thin metal plates.